Odor Conversion Method

A technology of odor and excrement, which is applied in the field of odor transformation, can solve the problems that the odor is difficult to completely disappear, and the odor cannot be deodorized, so as to achieve the effect of reducing the unpleasant feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

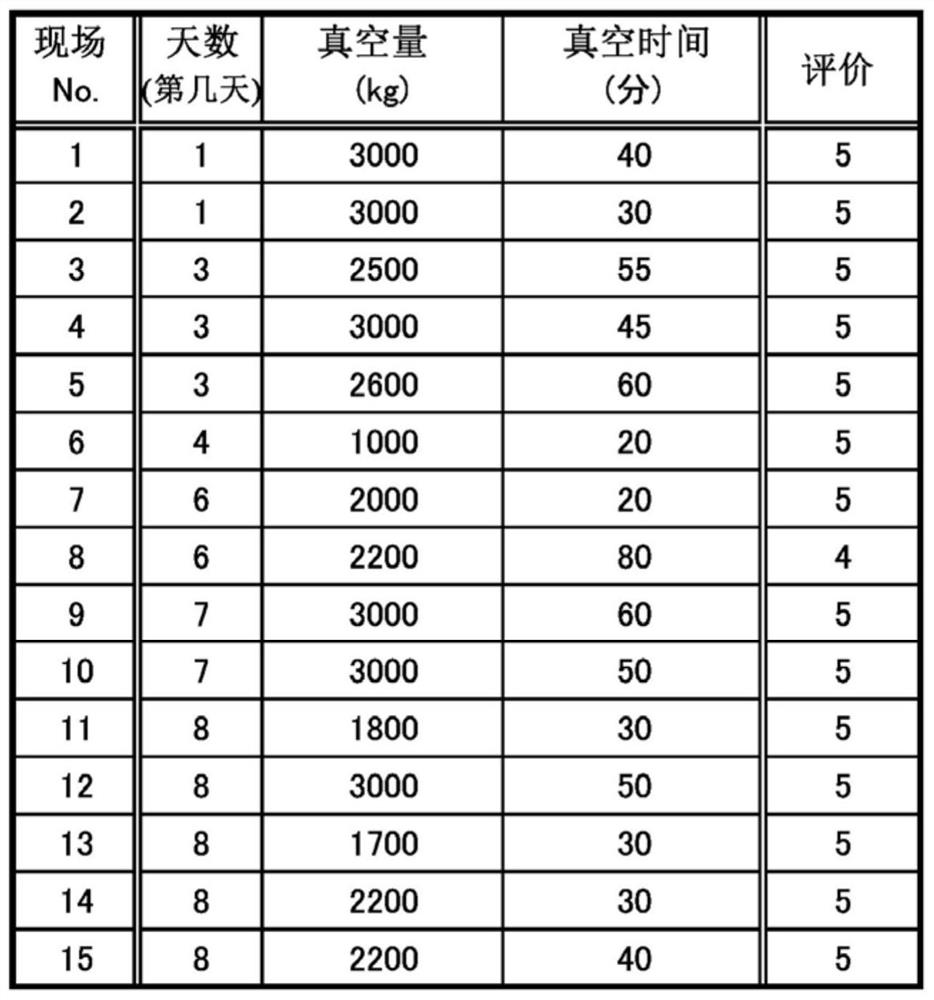

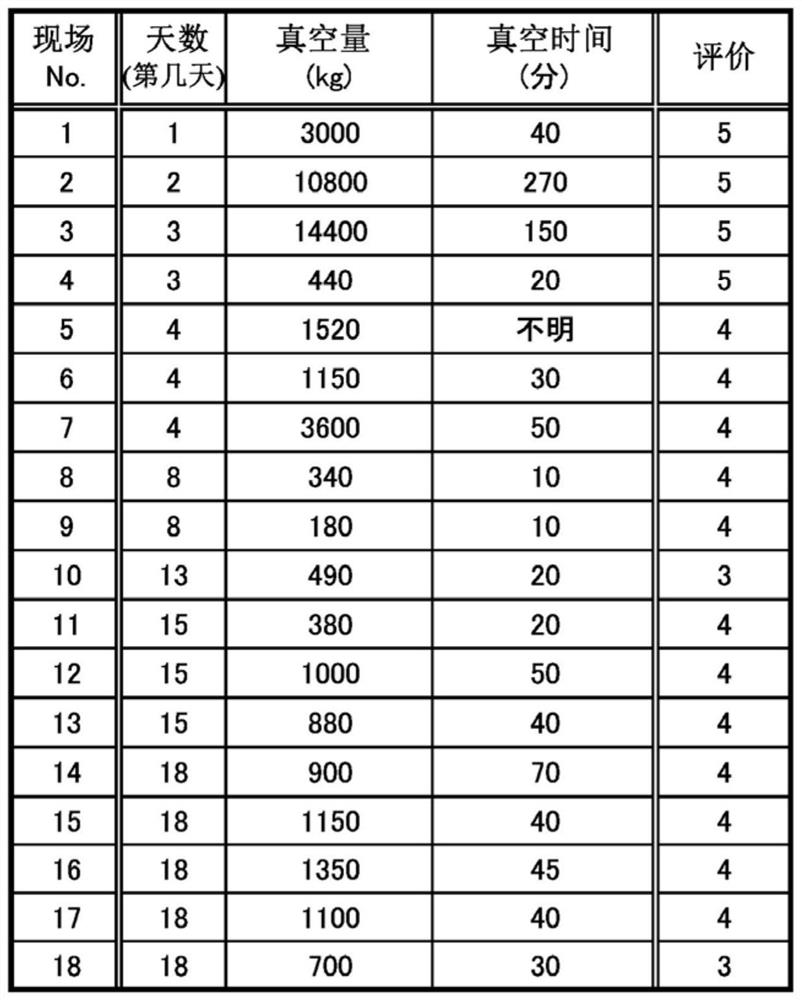

Examples

Embodiment 1

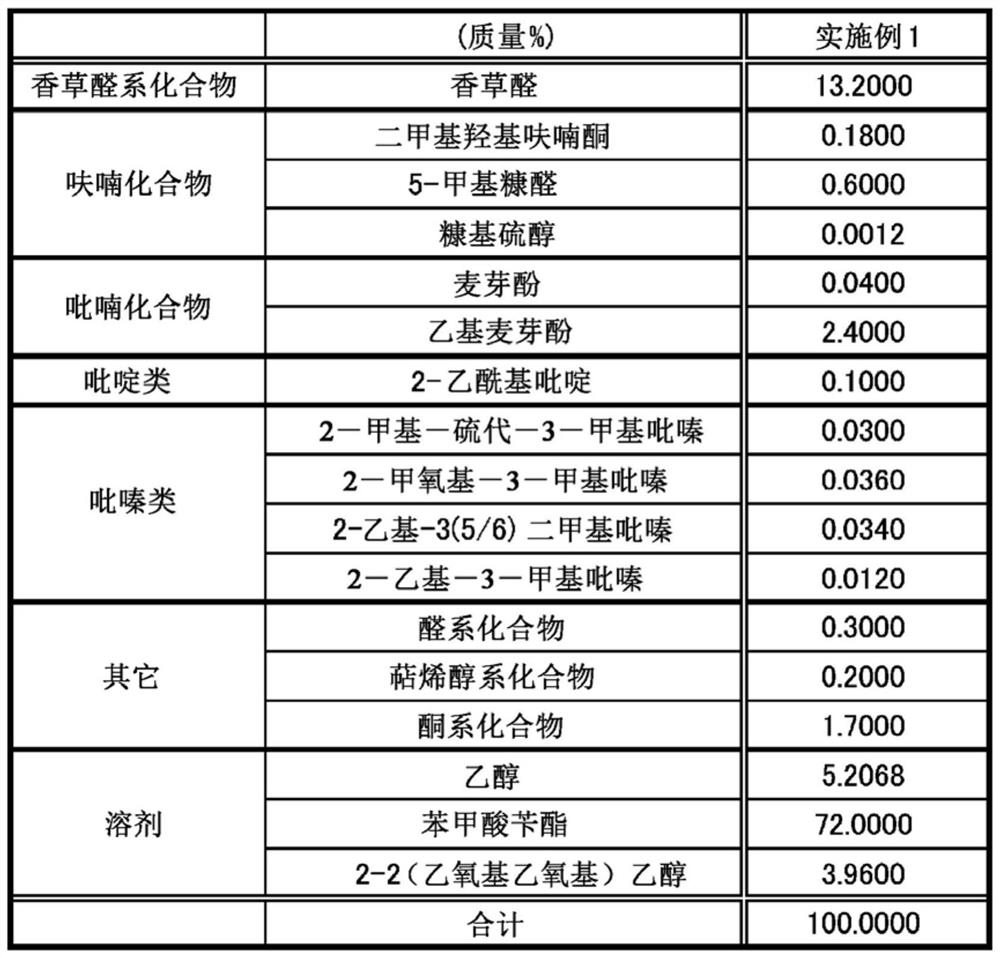

[0101] (Preparation of Odor Converting Components)

[0102] The raw materials of the odor conversion components shown in Table 1 were put into a mixing tank, mixed and stirred, and an odor conversion component was prepared. Specifically, a solvent was put into a mixing tank equipped with a heating device according to the compounding method shown in Table 1, and then other raw materials were sequentially added, and stirred at 20° C. for 30 minutes to prepare an odor conversion component.

[0103] (Preparation of oil agent for odor conversion)

[0104] As an oil component, sorbitan monooleate (HLB is 4.3) was prepared, and the odor conversion component prepared above and sorbitan monooleate were prepared in a mass ratio of 1:1. Method Mix at room temperature in a mixing tank to prepare an oil agent for odor conversion.

[0105] (preparation of lubricating oil)

[0106] 50 cc of the oil agent for odor transformation prepared above and 4950 cc of lubricating oil were filled in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com