Mud base porcelain plate rolling forming device with facilitated base taking

A roll forming and mud blank technology is applied in the field of porcelain slab blank processing, which can solve the problems of low firing rate of porcelain slabs, low production efficiency, and high maintenance costs, and achieve low use costs, improved production efficiency, and maintenance costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

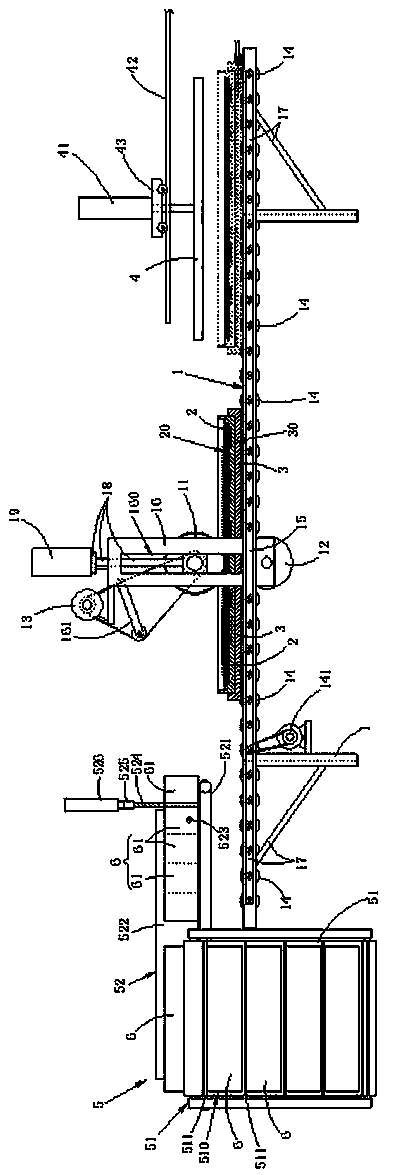

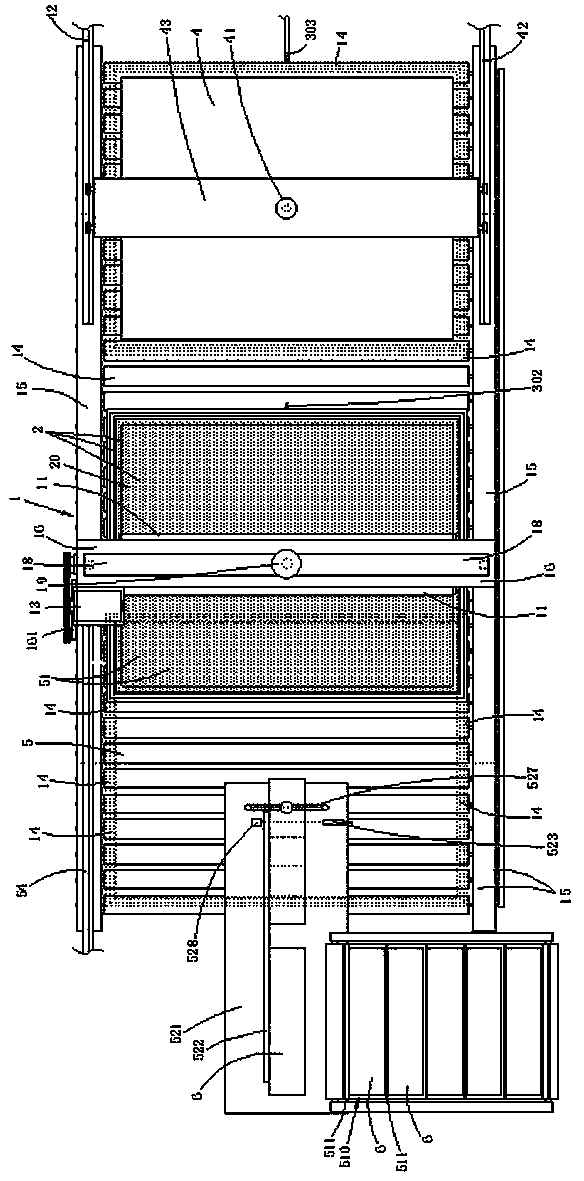

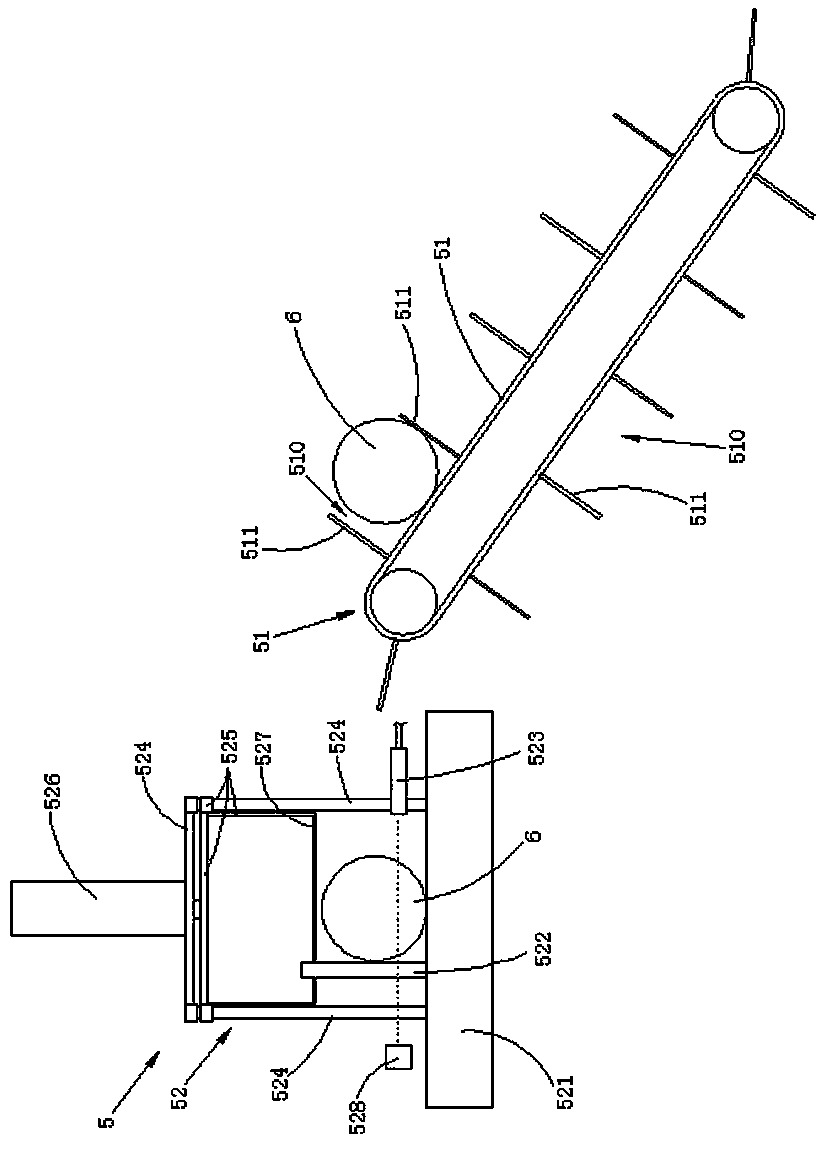

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0024] refer to figure 1 , figure 2 , the roll-forming device for mud ceramic slabs that is convenient for taking blanks, including a main frame 1 and an upper pressure roller 11 assembled on the main frame 1, a lower pressure roller 12, a pressure roller motor 13 and a number of parallel transmission rollers 14, The pressure roller motor 13 drives the upper pressure roller 11 to rotate, the upper pressure roller 11 can be adjusted vertically up and down, and the lower pressure roller 12 is a driven roller with a fixed position. It also includes a forming mold 2 placed on the above-mentioned conveying roller 14, the porcelain slab mud is placed in the forming cavity 20 of the forming mold 2, and the forming mold 2 horizontally passes between the above-mentioned upper pressing roller 11 and the lower pressing roller 12, The periphery of the upper pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com