A method of forming a strong antibacterial layer on the surface of polylactic acid

A technology of polylactic acid and antibacterial layer, applied in the field of materials, can solve the problems of insufficient utilization of antibacterial agents, high price, and inability to play a role

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

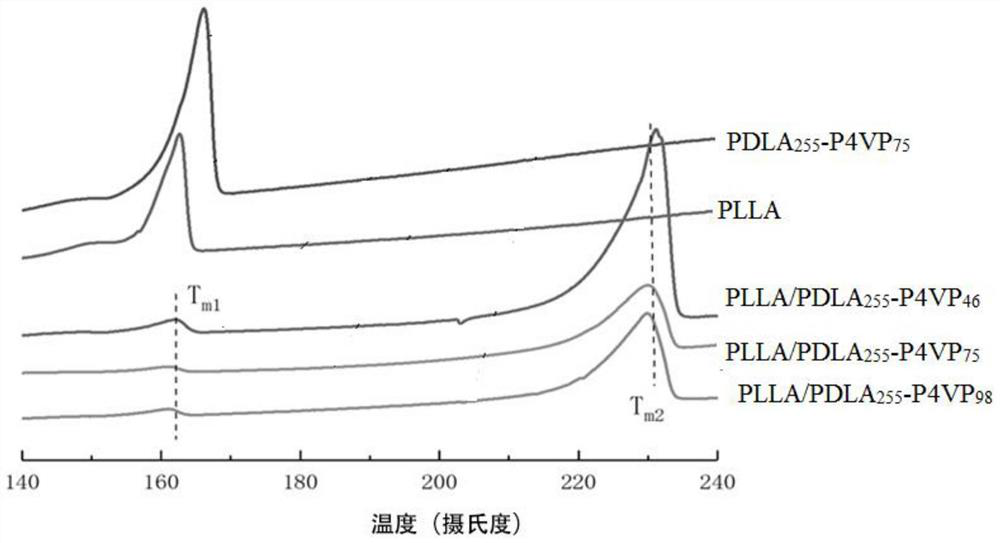

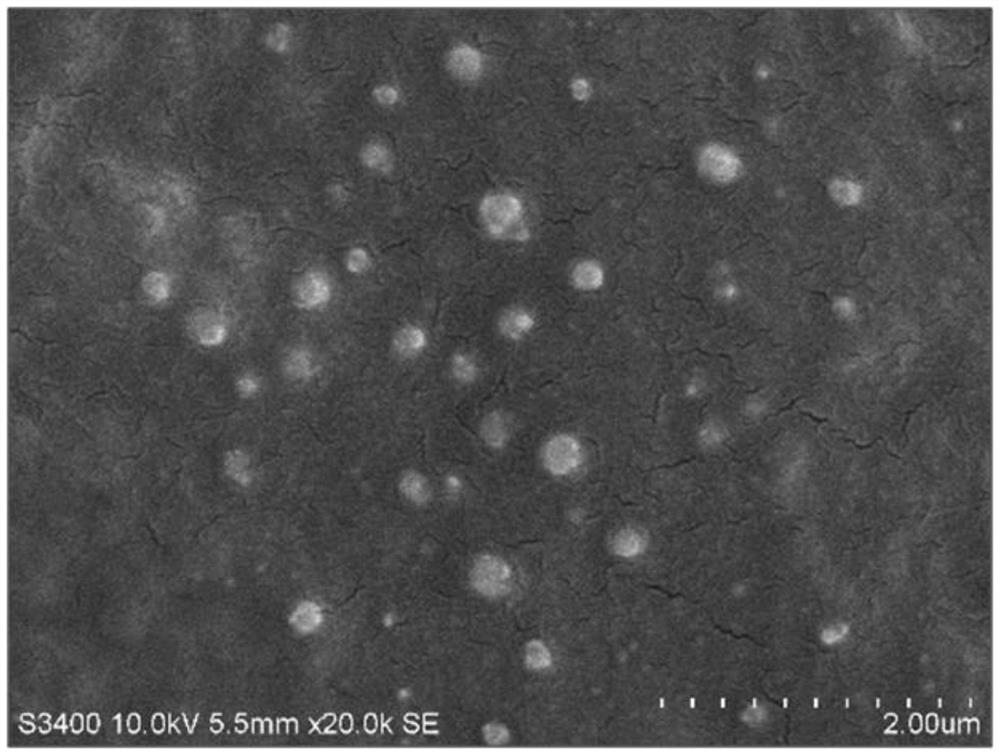

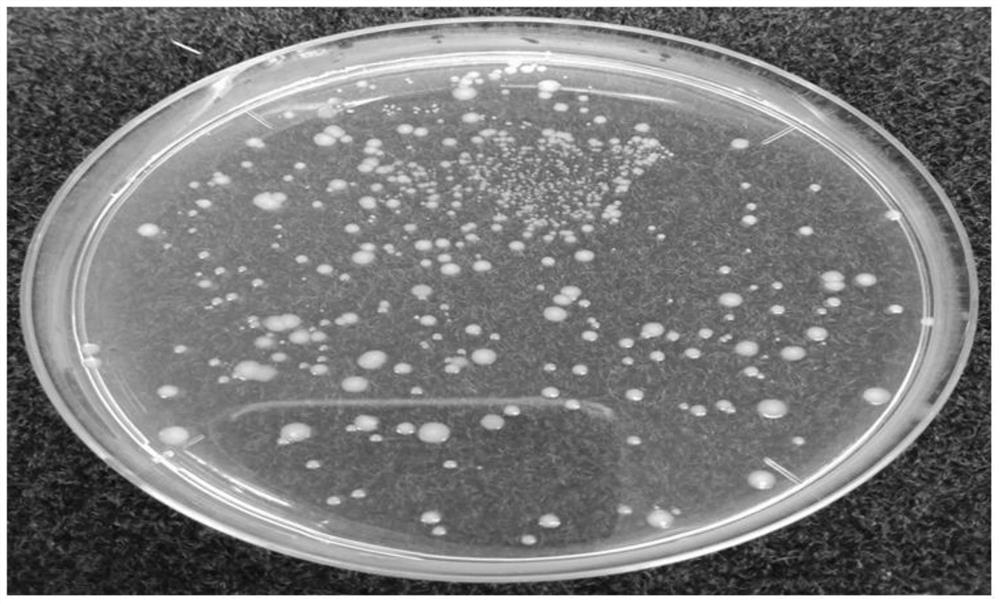

Method used

Image

Examples

Embodiment 1

[0037] A method for forming a strong antibacterial layer on the surface of polylactic acid, comprising the following steps:

[0038] The first step, prepare the macromolecular initiator containing Br

[0039] First, add D-lactide, hydroxyethyl isobromobutyrate and catalyst stannous octoate at a molar ratio of 1:1:1 to a 100mL branch bottle, then add 30mL of solvent toluene to a 100mL branch bottle At one-third of the capacity, stir and dissolve at room temperature, pass nitrogen into the bottle to replace the air three times, then protect it, raise the temperature to 100-150°C, stop the reaction after 3-6 hours, and precipitate and filter the product with ice ether to obtain The white powder is a macromolecular initiator containing Br, GPC data (molecular weight is 12000~24000, the present example molecular weight is about 18000), 1 HNMR (400MHz, DMSO-d6) δ5.21 (q, J = 6.9Hz, 2H), 1.89 (d, J = 11.4Hz, OH), 1.47 (d, J = 7.0Hz, 6H), 1.31–1.13 ( m,1H).

[0040] The second step...

Embodiment 2

[0048] A method for forming a strong antibacterial layer on the surface of polylactic acid, comprising the following steps:

[0049] The first step, prepare the macromolecular initiator containing Br

[0050] First, add D-lactide, hydroxyethyl isobromobutyrate and catalyst stannous octoate at a molar ratio of 1:1:1 to a 100mL branch bottle, then add 30mL of solvent toluene to a 100mL branch bottle At one-third of the capacity, stir and dissolve at room temperature, pass nitrogen into the bottle to replace the air three times, then protect it, raise the temperature to 100-150°C, stop the reaction after 3-6 hours, and precipitate and filter the product with ice ether to obtain The white powder is a macromolecular initiator containing Br, GPC data (molecular weight is 12000~24000, the present example molecular weight is about 18000), 1 ( m,1H).

[0051] The second step is to prepare D-polylactic acid-polytetravinylpyridine PDLA-P4VP block polymer

[0052] In a check bottle, a...

Embodiment 3

[0058] A method for forming a strong antibacterial layer on the surface of polylactic acid, comprising the following steps:

[0059] The first step, prepare the macromolecular initiator containing Br

[0060] First, add D-lactide, hydroxyethyl isobromobutyrate and catalyst stannous octoate at a molar ratio of 1:1:1 to a 100mL branch bottle, then add 30mL of solvent toluene to a 100mL branch bottle At one-third of the capacity, stir and dissolve at room temperature, pass nitrogen into the bottle to replace the air three times, then protect it, raise the temperature to 100-150°C, stop the reaction after 3-6 hours, and precipitate and filter the product with ice ether to obtain The white powder is a macromolecular initiator containing Br, GPC data (molecular weight is 12000~24000, the present example molecular weight is about 18000), 1 HNMR (400MHz, DMSO-d6) δ5.21 (q, J = 6.9Hz, 2H), 1.89 (d, J = 11.4Hz, OH), 1.47 (d, J = 7.0Hz, 6H), 1.31–1.13 ( m,1H).

[0061] The second step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com