Preparation method of antibacterial and wear-resistant plastic used by children toys

A technology of children's toys and plastics, which is applied in the field of plastic product processing, can solve the problems of antibacterial safety performance not meeting the requirements, and achieve good antibacterial effect, improved friction performance, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

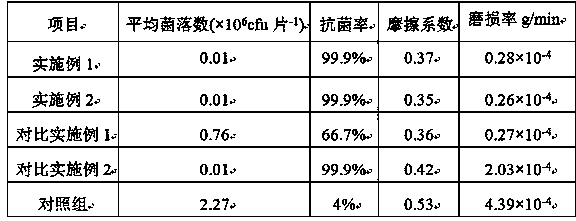

Examples

Embodiment 1

[0025] A preparation method of antibacterial and wear-resistant plastics for children's toys is characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0026] (1) Preparation of compound antibacterial agent:

[0027] Add 1 part of nano-titanium dioxide 1:10 into ethanol aqueous solution, high-speed shear fraction for 10 minutes, adjust pH to 8, disperse by ultrasonic oscillation for 20 minutes, add 0.15 parts of silane coupling agent dropwise, stir and reflux reaction in 70°C oil bath for 2 hours, centrifuge 1. Wash 3 times with absolute ethanol, and vacuum-dry to obtain coupling agent-modified nano-titanium dioxide, add it and 0.17 parts of chlorophyll cupric acid 1:10 to absolute ethanol, then add 2 parts of surface-modified nano-zinc oxide, magnetically stir Centrifuge after uniformity, and vacuum-dry at 80°C to obtain a composite antibacterial agent;

[0028] Wherein, the volume fraction of ethanol aqueo...

Embodiment 2

[0036] A preparation method of antibacterial and wear-resistant plastics for children's toys is characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0037] (1) Preparation of compound antibacterial agent:

[0038] Add 2 parts of nano-titanium dioxide 1:10 into ethanol aqueous solution, high-speed shear fraction for 20 minutes, adjust pH to 8, disperse by ultrasonic vibration for 30 minutes, add 0.3 parts of silane coupling agent dropwise, stir and reflux reaction in 75°C oil bath for 2 hours, centrifuge 1. Wash 5 times with absolute ethanol, and vacuum-dry to obtain coupling agent-modified nano-titanium dioxide, add it and 0.33 parts of chlorophyll cupric acid 1:10 in absolute ethanol, then add 4 parts of surface-modified nano-zinc oxide, magnetically stir Centrifuge after uniformity, and vacuum-dry at 85°C to obtain a composite antibacterial agent;

[0039] Wherein, the volume fraction of ethanol aqueous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com