Method for forming strong antibacterial layer on surface of polylactic acid

A technology of polylactic acid and antibacterial layer, applied in the field of materials, can solve the problems of high price, insufficient utilization of antibacterial agents, inability to exert efficacy, etc., and achieve the effect of simple processing process and high antibacterial properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

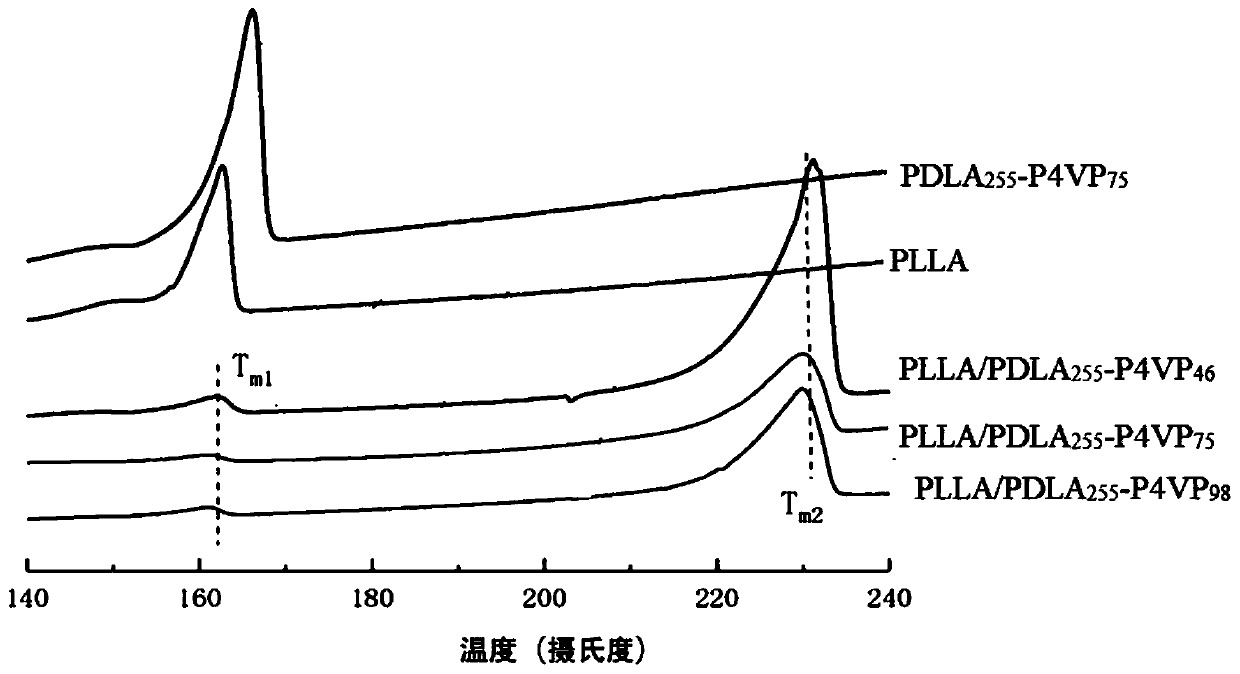

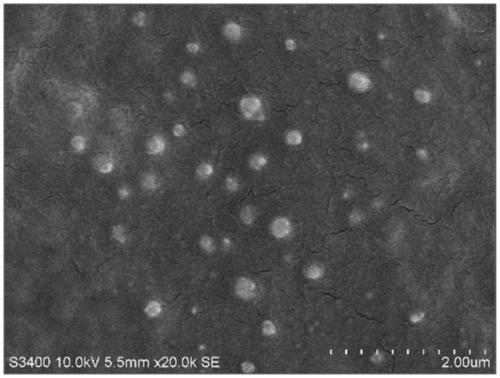

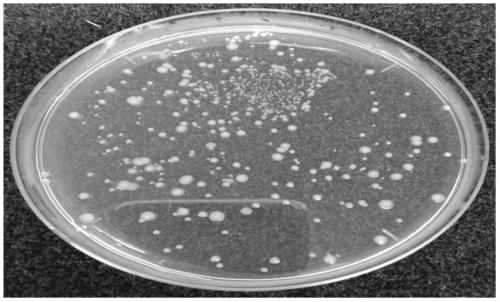

Image

Examples

Embodiment 1

[0037] A method for forming a strong antibacterial layer on the surface of polylactic acid includes the following steps:

[0038] The first step is to prepare a macroinitiator containing Br

[0039] First, add D-lactide, hydroxyethyl isobromobutyrate and catalyst stannous octoate in a molar ratio of 1:1:1 to a 100mL vial, and then add 30mL toluene as a solvent to a 100mL vial One-third of the volume, stir and dissolve at room temperature, pass nitrogen into the bottle to replace the air three times, and protect it. The temperature is raised to 100~150℃, and the reaction is stopped after 3~6h. The product is precipitated and filtered with ice ether to obtain The white powder is a macromolecular initiator containing Br, GPC data (molecular weight is 12000-24000, the molecular weight of this example is about 18000), 1 HNMR(400MHz,DMSO-d6)δ5.21(q,J=6.9Hz,2H), 1.89(d,J=11.4Hz,OH), 1.47(d,J=7.0Hz,6H), 1.31-1.13( m,1H).

[0040] The second step is to prepare D-polylactic acid-polytetravin...

Embodiment 2

[0048] A method for forming a strong antibacterial layer on the surface of polylactic acid includes the following steps:

[0049] The first step is to prepare a macroinitiator containing Br

[0050] First, add D-lactide, hydroxyethyl isobromobutyrate and catalyst stannous octoate in a molar ratio of 1:1:1 to a 100mL vial, and then add 30mL toluene as a solvent to a 100mL vial One-third of the volume, stir and dissolve at room temperature, pass nitrogen into the bottle to replace the air three times, and protect it. The temperature is raised to 100~150℃, and the reaction is stopped after 3~6h. The product is precipitated and filtered with ice ether to obtain The white powder is a macromolecular initiator containing Br, GPC data (molecular weight is 12000-24000, the molecular weight of this example is about 18000), 1 HNMR (400MHz, DMSO-d6) δ 5.21 (q, J = 6.9 Hz, 2H), 1.89 (d, J = 11.4 Hz, 1H), 1.47 (d, J = 7.0 Hz, 6H), 1.31-1.13 ( m,1H).

[0051] The second step is to prepare D-polyl...

Embodiment 3

[0058] A method for forming a strong antibacterial layer on the surface of polylactic acid includes the following steps:

[0059] The first step is to prepare a macroinitiator containing Br

[0060] First, add D-lactide, hydroxyethyl isobromobutyrate and catalyst stannous octoate in a molar ratio of 1:1:1 to a 100mL vial, and then add 30mL toluene as a solvent to a 100mL vial One-third of the volume, stir and dissolve at room temperature, pass nitrogen into the bottle to replace the air three times, and protect it. The temperature is raised to 100~150℃, and the reaction is stopped after 3~6h. The product is precipitated and filtered with ice ether to obtain The white powder is a macromolecular initiator containing Br, GPC data (molecular weight is 12000-24000, the molecular weight of this example is about 18000), 1 HNMR(400MHz,DMSO-d6)δ5.21(q,J=6.9Hz,2H), 1.89(d,J=11.4Hz,OH), 1.47(d,J=7.0Hz,6H), 1.31-1.13( m,1H).

[0061] The second step is to prepare D-polylactic acid-polytetravin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com