Nozzle throat section with annular reinforcing ribs

A technology of ring-shaped ribs and throats, applied in the direction of pipes, rigid pipes, pipeline heating/cooling, etc., can solve the problems of nozzle throat section scrapping, delaying scientific research and production progress, etc., to reduce the risk of instability and avoid The effect of destabilizing the throat section and enhancing the overall stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

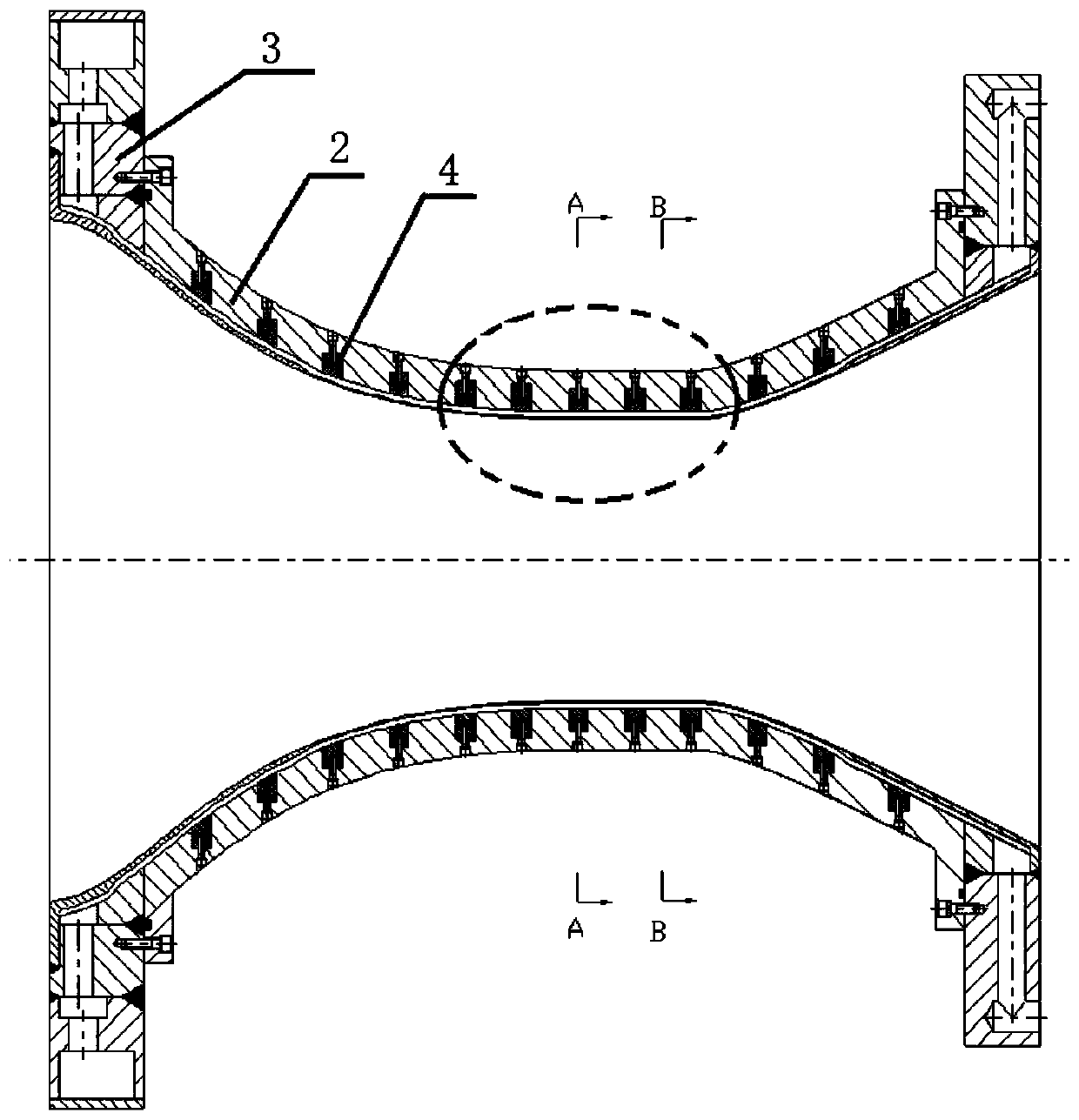

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0020] This embodiment provides a nozzle throat section with an annular reinforcing rib, and the nozzle throat section of this structural form can meet the requirement of high Mach number.

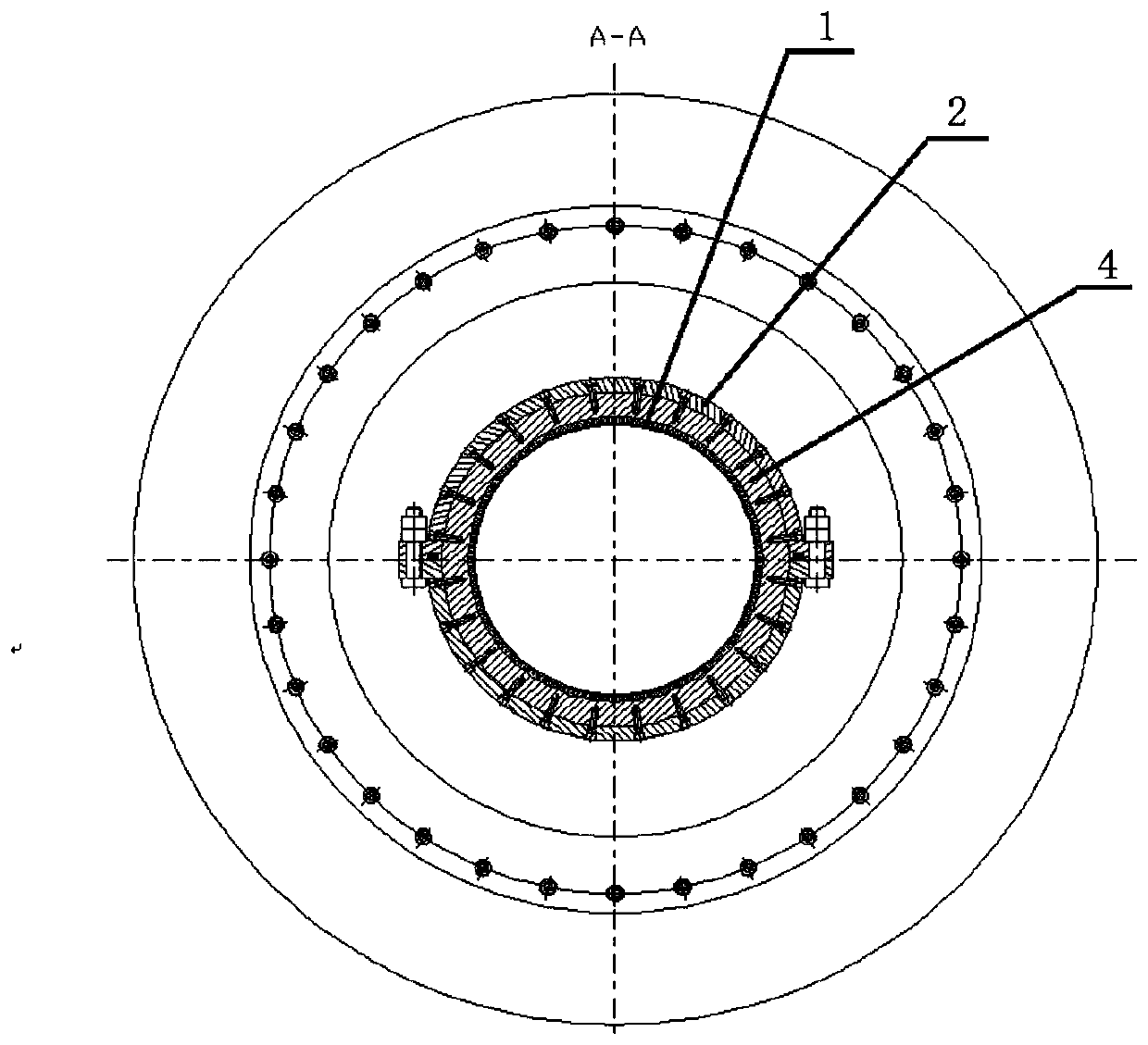

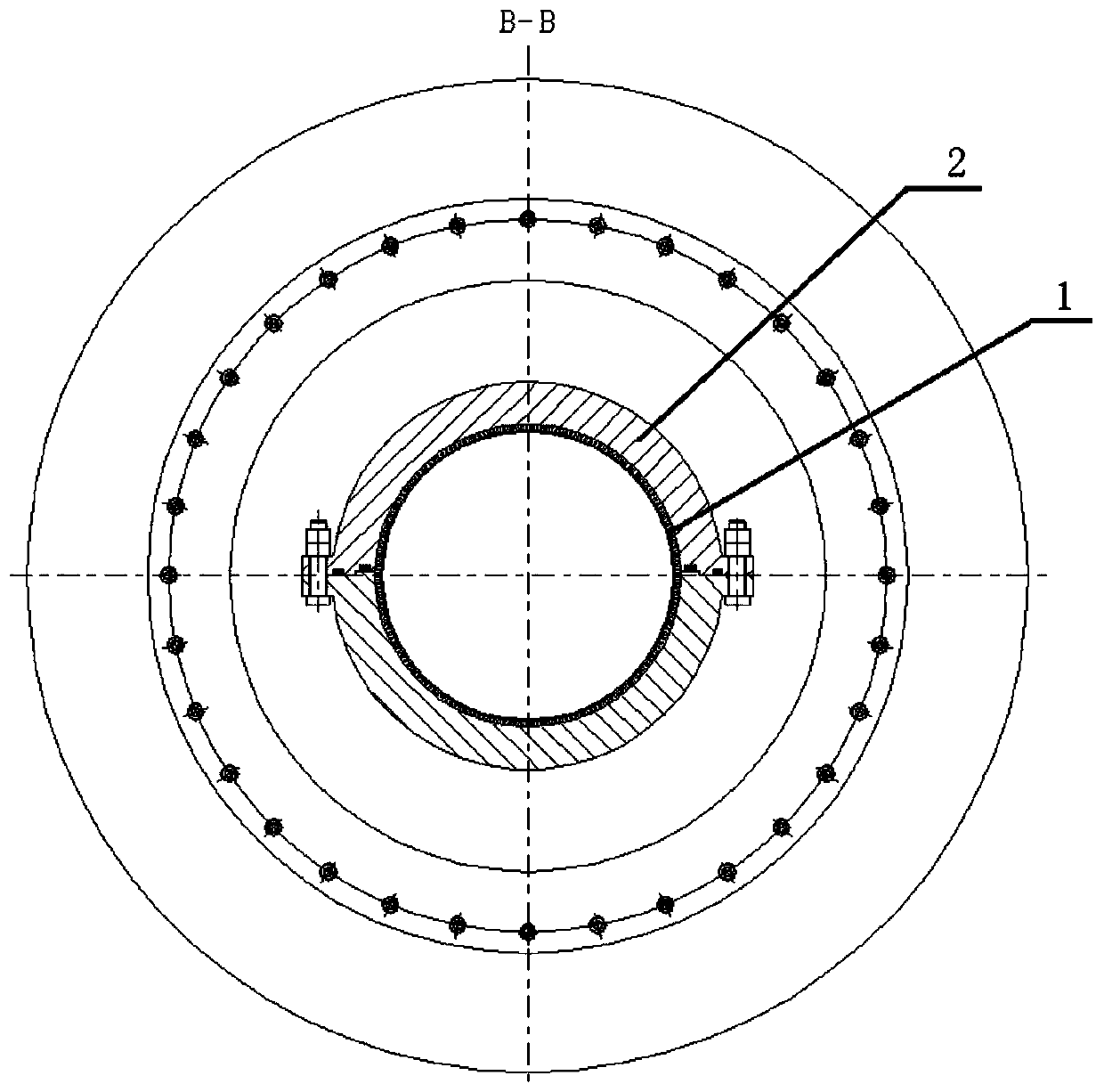

[0021] Such as Figure 1-6 As shown, the throat section of the nozzle includes: an inner cylinder 1 and an outer cylinder 2 coaxially set outside the inner cylinder 1, connecting flanges 3 are respectively arranged at both axial ends of the outer cylinder 2, and the inner cylinder The outer peripheral surface of the body 1 is evenly distributed in the axial direction with more than two annular reinforcing ribs 4; the outer peripheral surface of the inner cylinder 1 is processed with strip grooves in the axial direction as cold water tanks, and multiple cold water tanks are arranged along the inner cylinder 1. Evenly distributed in the circumferential direction; the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com