A Simple Low Temperature Dewax Cleaning Process for LED Wafers

A chip and simple technology, applied in the field of optoelectronics, can solve the problems of unfavorable production efficiency, lower product cost, cumbersome equipment and wax removal methods, etc., and achieve the effect of improving wax removal and cleaning ability, improving production efficiency, and high quality of wax removal and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

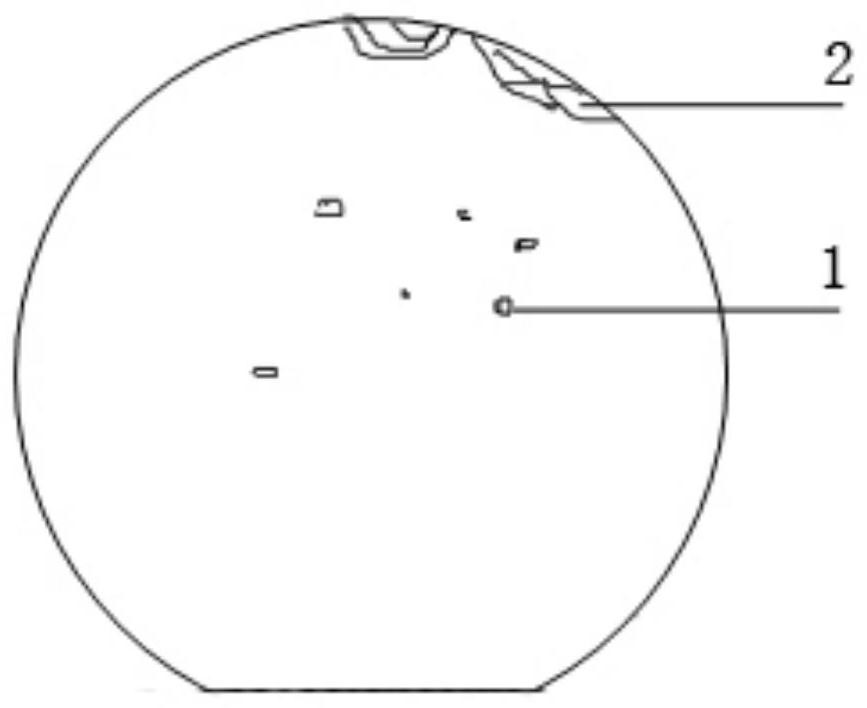

Image

Examples

Embodiment 1

[0037] A simple low-temperature dewaxing and cleaning process for LED wafers, the steps include:

[0038] (1) Take the wafers to be dewaxed and cleaned and put them into the cleaning flower basket in turn;

[0039] (2) Put the flower basket to be cleaned in step (1) into 2 liters of wax-removing solution at a temperature of 45°C for ultrasonic cleaning. During the cleaning process, the flower basket is in a state of vibrating up and down in the wax-removing solution with a vibration frequency of 15 times / min. The frequency is 24KHz, and the cleaning time is 15 minutes;

[0040] (3) Place the flower basket after ultrasonic cleaning in step (2) in room temperature acetone solution with a purity of 99.5% for 10 minutes;

[0041] (4) Place the flower basket cleaned in step (3) in room temperature ethanol solution with a purity of 99.7% for 3 minutes;

[0042] (5) Dry the flower basket cleaned in step (4) with hot nitrogen at a drying temperature of 38°C and a drying time of 9 mi...

Embodiment 2

[0045] A simple low-temperature dewaxing and cleaning process for LED wafers, the steps are as follows:

[0046] (1) Put the wafers to be dewaxed and cleaned into the cleaning flower basket in turn;

[0047] (2) Put the flower basket cleaned in step (1) into 2 liters of wax-removing solution at a temperature of 40°C for ultrasonic cleaning. During the cleaning process, the flower basket is in a state of vibration up and down in the wax-removing solution. The vibration frequency is 27 times per minute, and the ultrasonic frequency 32KHz, cleaning time 10min;

[0048] (3) Place the flower basket after ultrasonic cleaning in step (2) in room temperature acetone solution with a purity of 99.5% for 7 minutes;

[0049] (4) Place the flower basket cleaned in step (3) in room temperature isopropanol solution with a purity of 99.7% for 2 minutes;

[0050] (5) Dry the flower basket cleaned in step (4) with hot nitrogen at a drying temperature of 51°C for 6 minutes.

[0051] Take out th...

Embodiment 3

[0053] A simple low-temperature dewaxing and cleaning process for LED wafers, the steps are as follows:

[0054] (1) Put the wafers to be dewaxed and cleaned into the cleaning flower basket in turn;

[0055] (2) Put the flower basket cleaned in step (1) into 2 liters of wax-removing solution at a temperature of 50°C for ultrasonic cleaning. During the cleaning process, the flower basket is in a state of vibration up and down in the wax-removing solution. 38KHz, cleaning time 5min;

[0056] (3) Place the flower basket after ultrasonic cleaning in step (2) in room temperature acetone solution with a purity of 99.5% for 4 minutes;

[0057] (4) Place the flower basket cleaned in step (3) in room temperature ethanol solution with a purity of 99.7% for 1 min;

[0058] (5) Dry the flower basket cleaned in step (4) with hot nitrogen at a drying temperature of 75°C for 3 minutes.

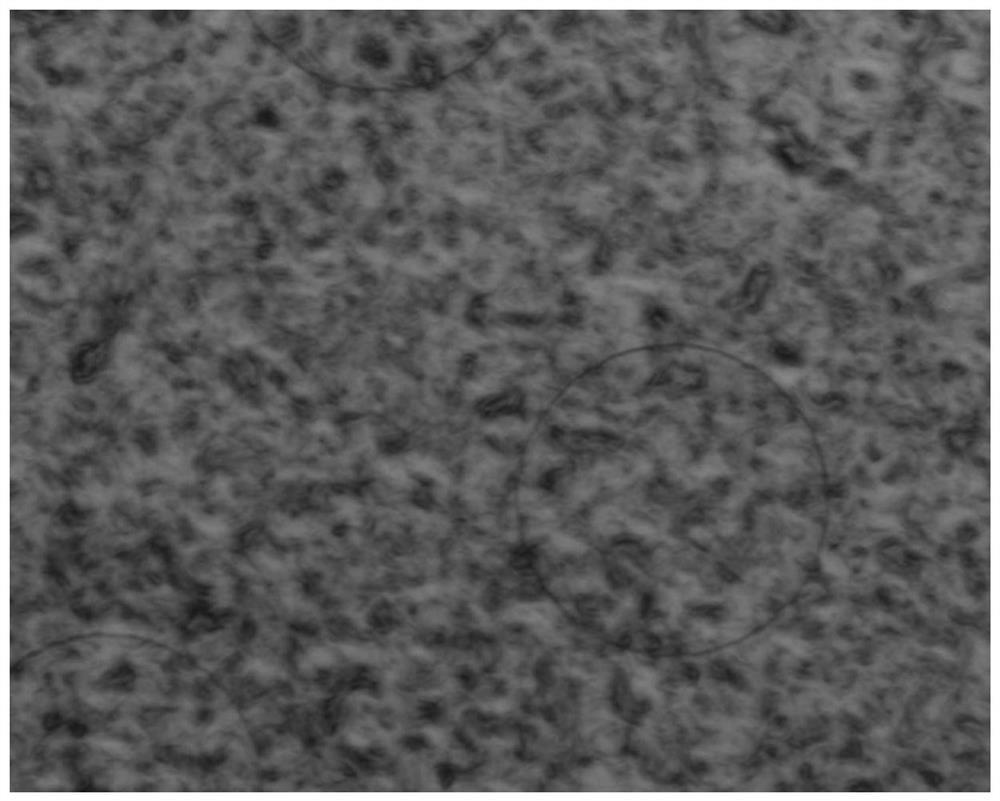

[0059] After cleaning, there is no residual wax or reagent imprint on the surface of the wafer, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap