Environmentally friendly U-shaped ring with high strength

A high-strength, U-shaped technology, applied in the field of U-shaped rings, can solve problems such as unfavorable operations, increase the working intensity of tower operators, and complicated operations, so as to achieve the effect of convenient locking and closing and improving anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

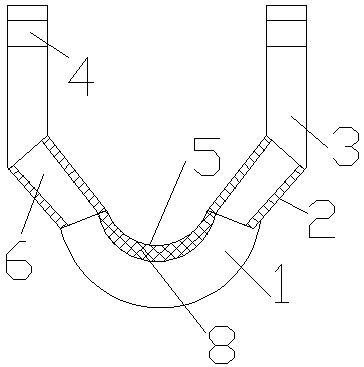

[0014] An environmentally friendly high-strength U-shaped ring is provided with a bottom ring 1, a guide rod 2 is arranged on the bottom ring 1, a connecting rod 3 is arranged on the upper end of the guide rod 2, and a connecting rod 3 is arranged on the upper end of the connecting rod 3 is provided with a connection hole 4, and an anti-oxidation component 5 is provided inside the bottom ring 1, and the anti-oxidation component 5 is set on the outside of the bottom ring 1.

[0015] A reinforcement rod 6 is arranged inside the guide rod 2, and the reinforcement rod 6 is a copper rod.

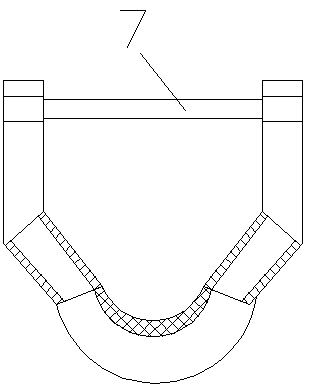

[0016] A limiting component 7 is arranged between the connecting rods 3, and the limiting component 7 is a limiting rod.

[0017] The anti-oxidation component 5 is an anti-oxidation copper sleeve, and an antioxidant coating 8 is coated on the copper sleeve.

Embodiment 2

[0019] An environmentally friendly high-strength U-shaped ring is provided with a bottom ring 1, a guide rod 2 is arranged on the bottom ring 1, a connecting rod 3 is arranged on the upper end of the guide rod 2, and a connecting rod 3 is arranged on the upper end of the connecting rod 3 is provided with a connection hole 4, and an anti-oxidation component 5 is provided inside the bottom ring 1, and the anti-oxidation component 5 is set on the outside of the bottom ring 1.

[0020] A reinforcement rod 6 is arranged inside the guide rod 2, and the reinforcement rod 6 is a copper rod.

[0021] A limiting component 7 is arranged between the connecting rods 3, and the limiting component 7 is a limiting rod.

[0022] The anti-oxidation component 5 is an anti-oxidation copper sleeve, and an antioxidant coating 8 is coated on the copper sleeve.

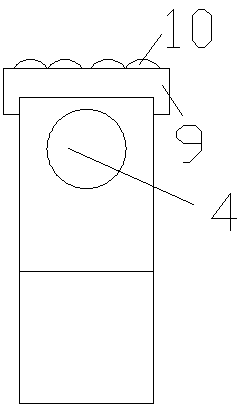

[0023] The upper end of the connecting rod 3 is provided with a protective cover 9, and the protective cover 9 is directly sleeved on the ...

Embodiment 3

[0025] An environmentally friendly high-strength U-shaped ring is provided with a bottom ring 1, a guide rod 2 is arranged on the bottom ring 1, a connecting rod 3 is arranged on the upper end of the guide rod 2, and a connecting rod 3 is arranged on the upper end of the connecting rod 3 is provided with a connection hole 4, and an anti-oxidation component 5 is provided inside the bottom ring 1, and the anti-oxidation component 5 is set on the outside of the bottom ring 1.

[0026] A reinforcement rod 6 is arranged inside the guide rod 2, and the reinforcement rod 6 is a copper rod.

[0027] A limiting component 7 is arranged between the connecting rods 3, and the limiting component 7 is a limiting rod.

[0028] The anti-oxidation component 5 is an anti-oxidation copper sleeve, and an antioxidant coating 8 is coated on the copper sleeve.

[0029] The upper end of the connecting rod 3 is provided with a protective cover 9, and the protective cover 9 is directly sleeved on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com