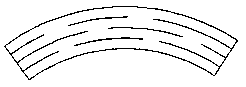

Fast and convenient group welding method of plane curved T ribbed slab unit

A flat curve, unit group technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of slow T-rib unit speed, etc., and achieve the effect of reducing the amount of correction, reducing the difficulty of assembly, and reducing welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0014] A quick method for welding flat curved T-rib units, the specific method is as follows:

[0015] S1: Blanking of the flange plate: during the blanking process of the curved T-rib top and bottom plate unit, when the T-rib flange plate on the same steel plate is single-piece blanked, a certain amount is reserved between each flange plate. The spacing is not cut off, even if the adjacent flange plates are connected as a whole, they will not be separated;

[0016] S2: Assembling and welding of T-rib webs: Assemble and weld T-rib webs on the steel plate of the integral flange plate of the fan, and perform unified correction after welding;

[0017] S3: Segmentation of T-rib: After the T-rib assembly, welding and correction are completed, it is cut and separated along the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com