Method for welding bridge cornice decorative sheets

A welding method and technology for decorative panels, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., to achieve the effect of reducing investment, preventing welding deformation, and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

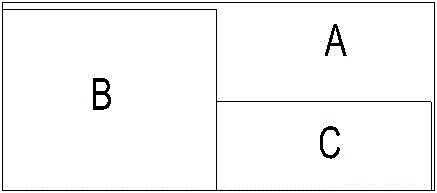

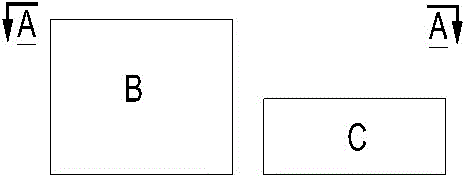

[0021] In order to better understand the present invention, below in conjunction with embodiment and accompanying drawing, technical scheme of the present invention is described further (as Figure 1-8 shown).

[0022] A bridge cornice decorative plate welding method is characterized in that it comprises the following steps:

[0023] Step 1. Cut the steel plate material A (that is, the steel plate with a thickness between 4mm and 8mm) into the required decorative plates B and C according to specific needs;

[0024] Step 2. Use a hammer to release the internal stress of decorative panels B and C around the decorative panels B and C, and level them (after the decorative panels are cut, the decorative panels B and C will be uneven because they are thin and the temperature is too high) ;

[0025] Step 3. Use low-voltage current for imposition welding of the leveled decorative panels B and C, and then use a hammer to hit the weld 1 on the welded part to release the internal stres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com