A multi-form grinding and polishing platform for the workpiece end face

A multi-form, face grinding technology, applied in machine tools designed for grinding workpiece rotating surfaces, grinding workpiece supports, grinding machine parts, etc., can solve problems affecting processing efficiency, inconvenient use, etc. Stable process, convenient use, and efficient vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

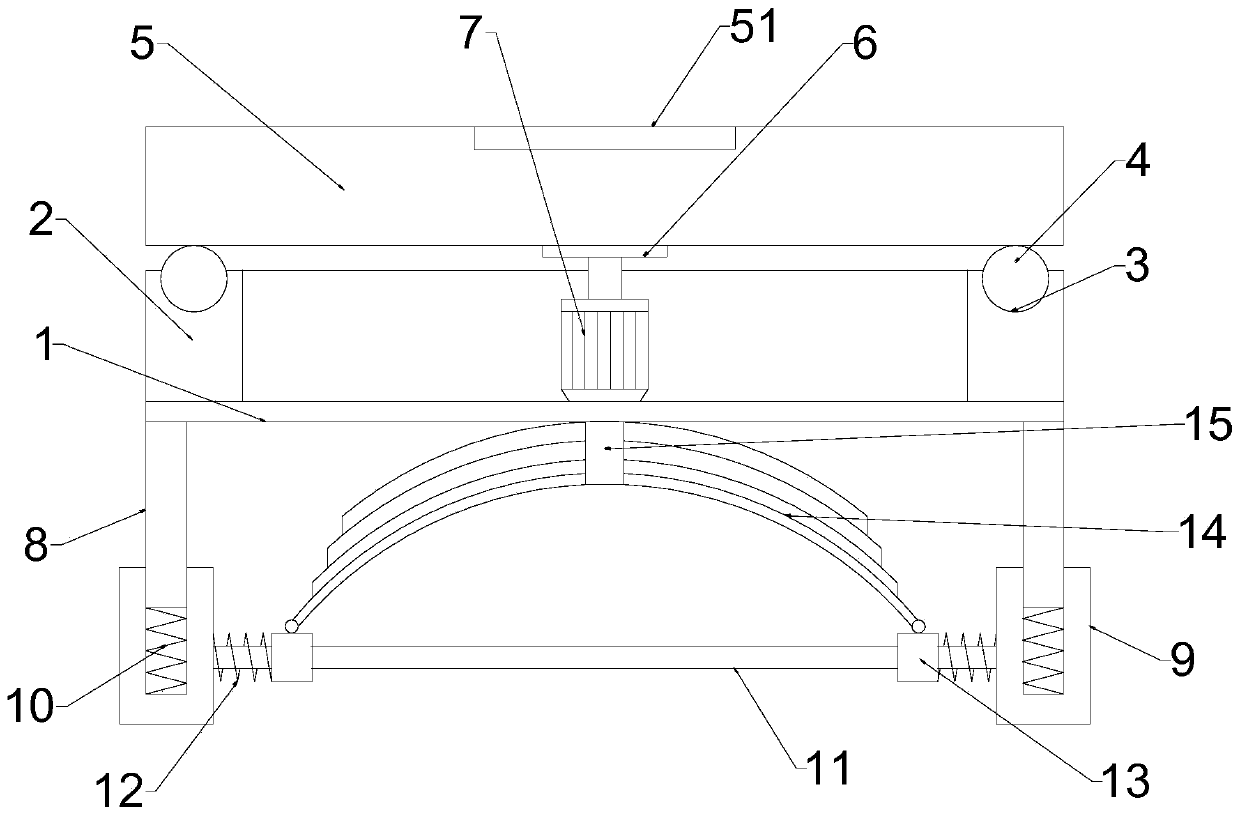

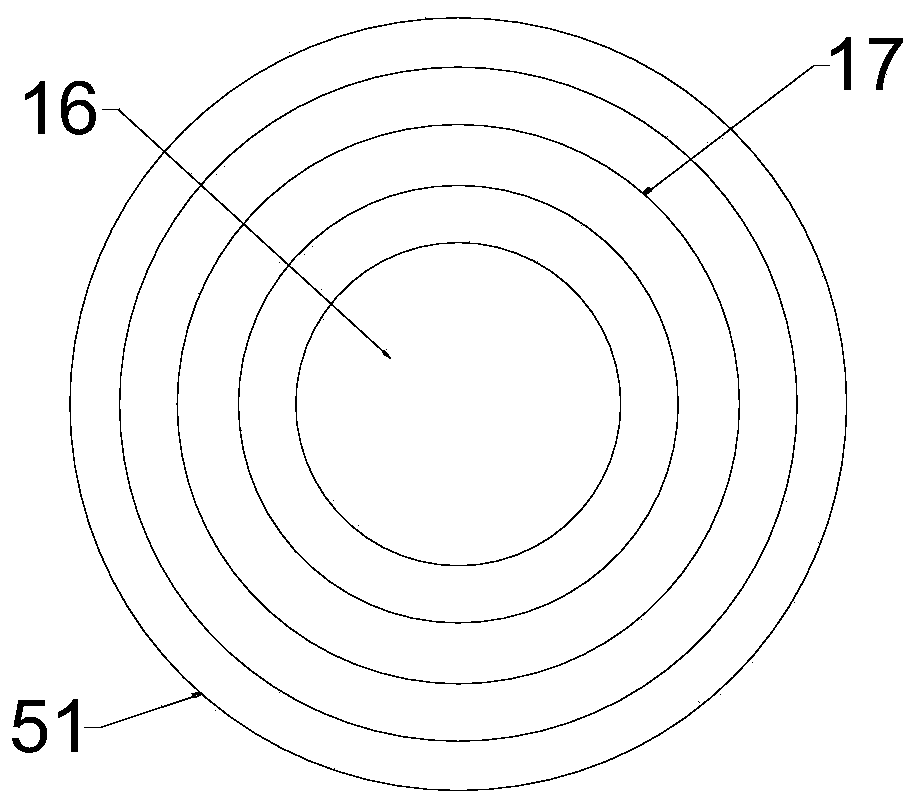

[0023] see Figure 1~2 , in an embodiment of the present invention, a workpiece end surface grinding and polishing platform for multi-form grinding includes a bottom plate 1, an annular side plate 2, a grinding platform 5, a motor 7 and a vibration-damping base, and the upper end of the annular side plate 2 is embedded with an annular Groove 3, a plurality of supporting balls 4 are provided for movable cooperation in the annular groove 3, a motor 7 is arranged in the middle of the bottom plate 1, and a grinding platform 5 is arranged on the upper end of the output end of the motor 7 through a liner plate 6. The upper end of the grinding platform 5 and the supporting ball 4 are movably attached, and the middle part of the upper end of the grinding platform 5 is embedded with a cover plate 51. The upper end of the cover plate 51 is pasted with a polished suede surface 16. The upper surface of the grinding platform 5 is Embedded with a grinding wheel surface 17, the grinding whee...

Embodiment 2

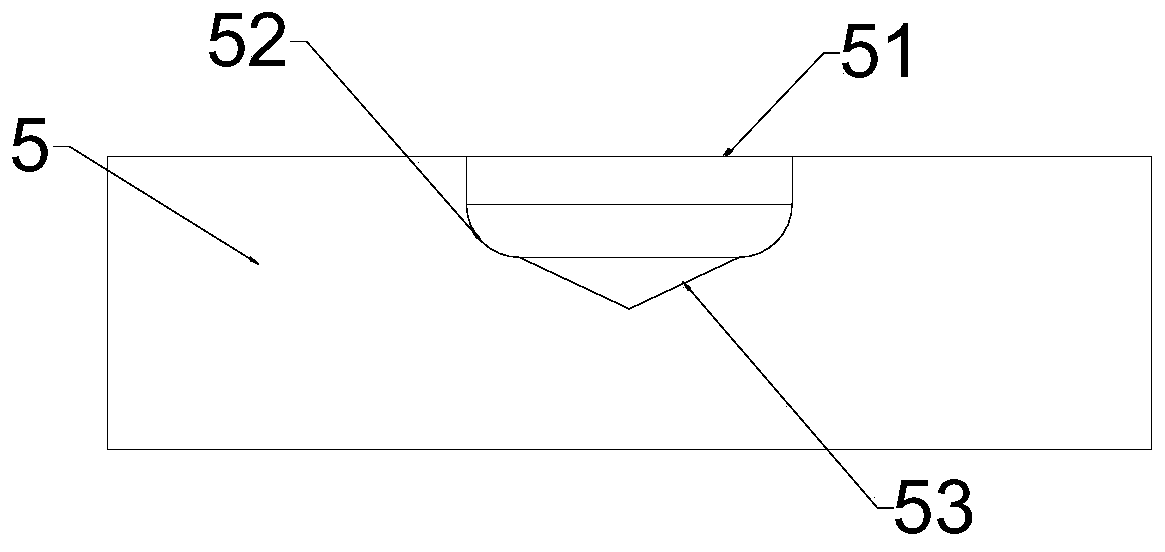

[0028] see image 3 , in the embodiment of the present invention, a workpiece end face grinding and polishing platform for multi-form grinding, on the basis of embodiment 1, the upper end of the grinding platform 5 is embedded with an arcuate groove 52, and the arcuate groove 52 is located Below the cover plate 51, the inner surface of the arcuate groove 52 is fitted with sandpaper, and the middle part of the arcuate groove 52 is embedded with a conical groove 53, and the surface of the conical groove 53 is disposed There is sandpaper.

[0029] Such a design can increase the grinding methods of the arc surface and the conical surface on the basis of the original grinding of the end face plane, and improves the variety of grinding.

[0030] The working principle of the present invention is: when in use, the starting motor 7 drives the grinding platform 5 to rotate through the lining plate 6, and the support ball 4 is movably connected in the annular groove 3, which can stably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com