Production process of display book cover

A production process and cover technology, which is applied to the production process field of exhibition book covers, can solve the problems of low bonding strength of hot melt adhesives, difficult to clean hot melt adhesives, and reduced aesthetics, so as to achieve easy cleaning, reduce energy consumption, improve The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

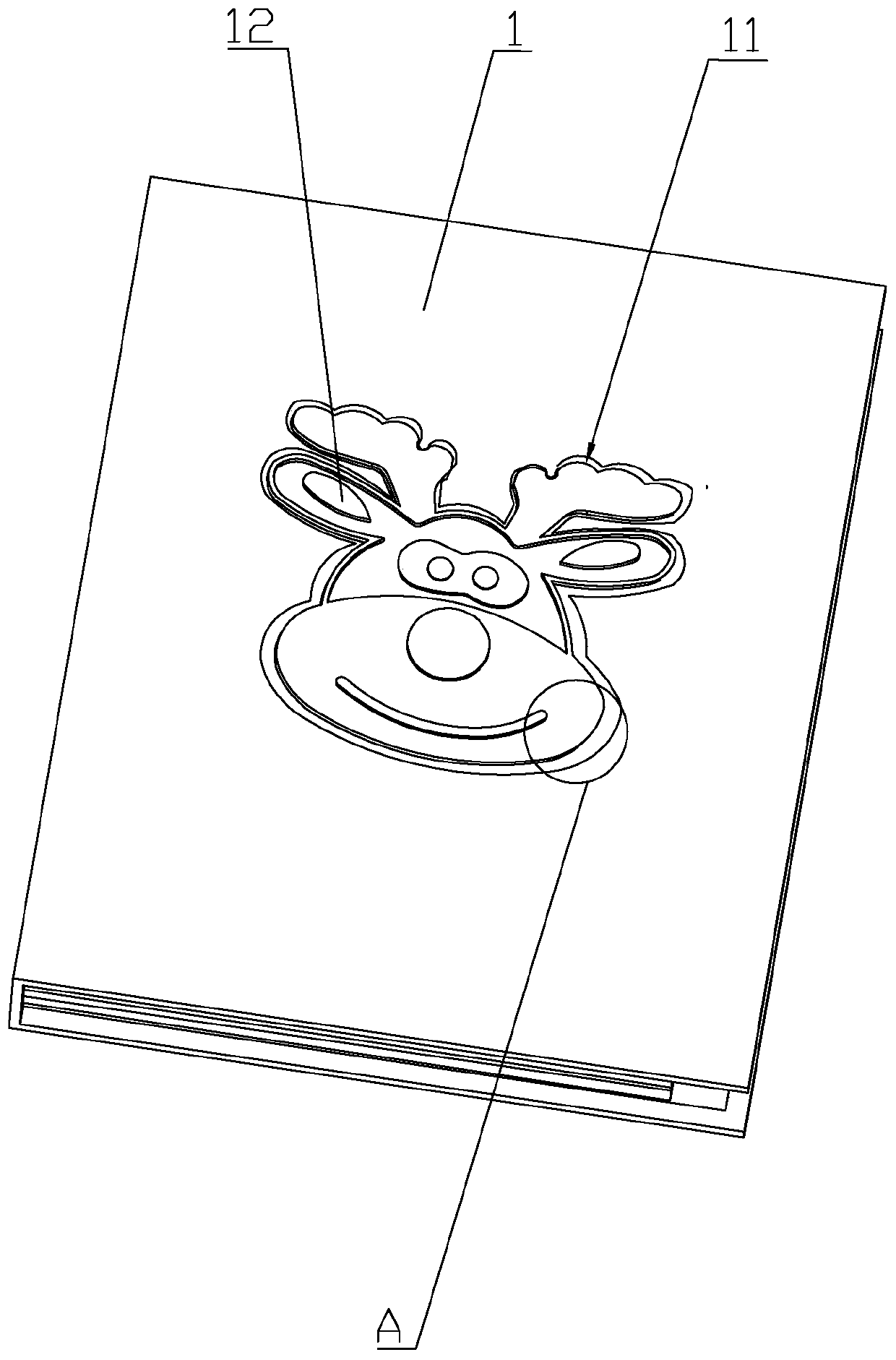

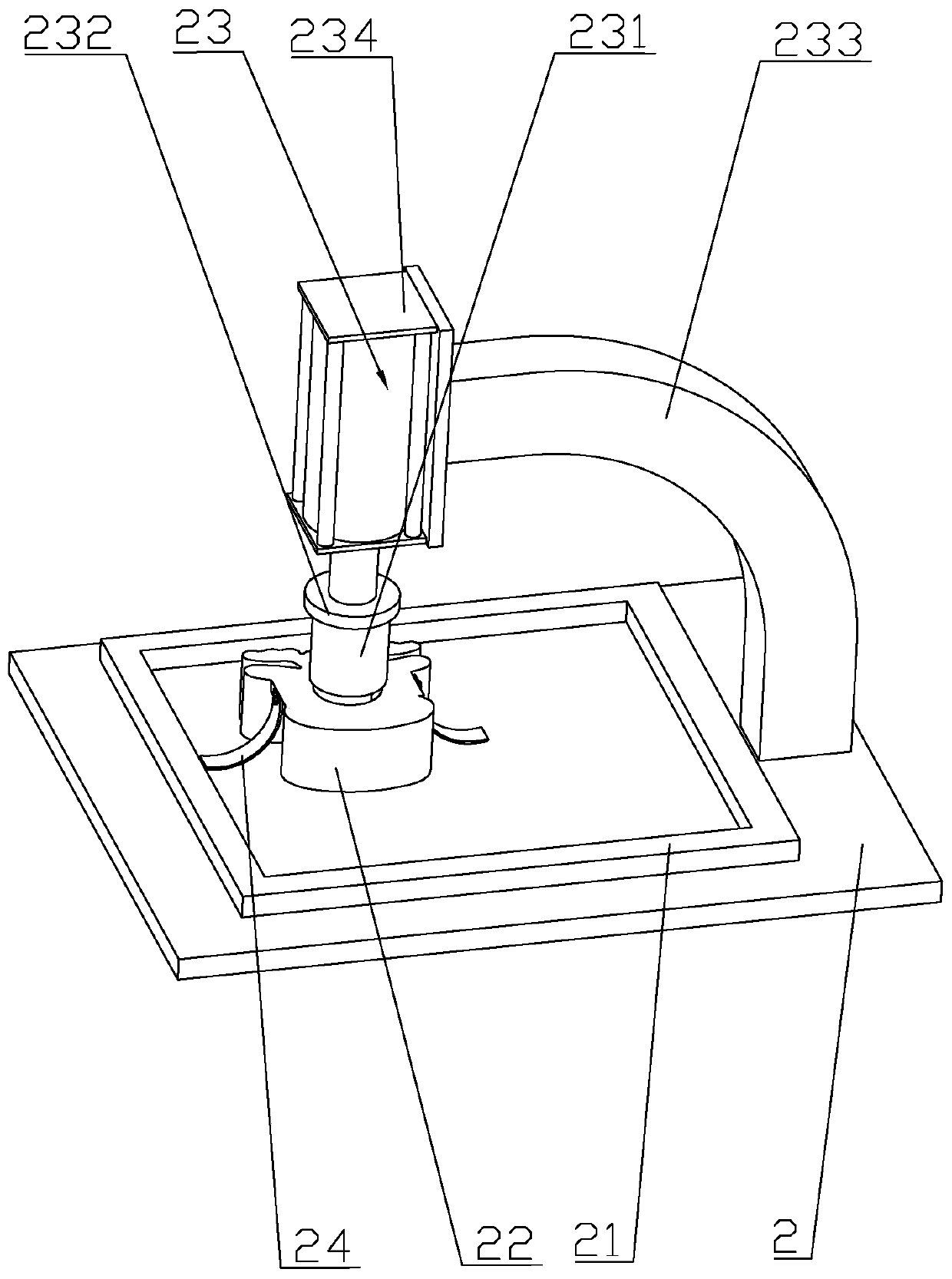

[0049] like figure 1 As shown in the figure, a manufacturing process of the cover 1 of the exhibition book includes the following steps:

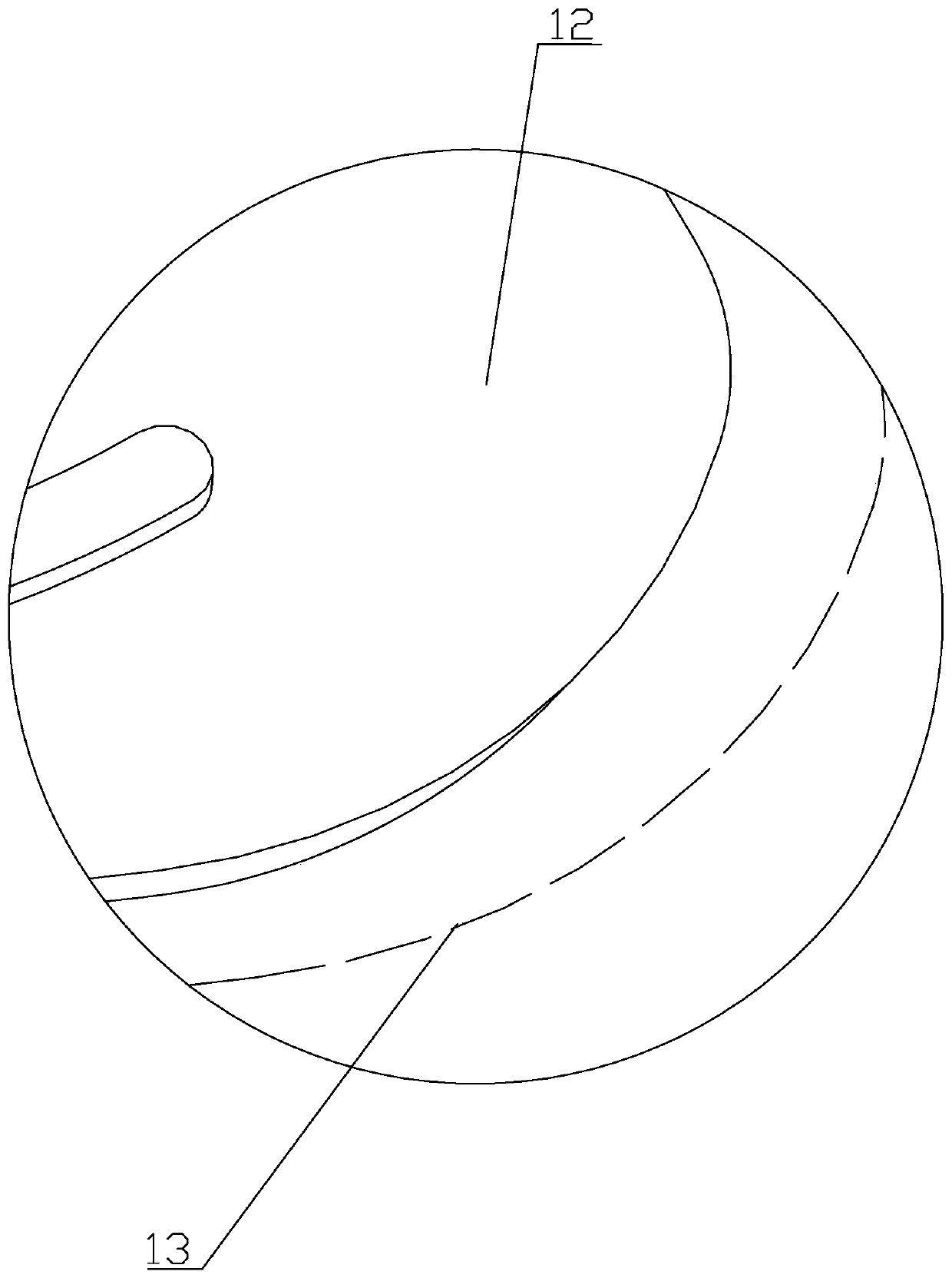

[0050] S100: A through hole 11 of a predetermined shape is opened on the cover 1 of the exhibition book by a die-cutting machine, and the cover 1 is preliminarily cut. By opening a through hole 11 of a predetermined shape on the cover 1 , the position of the ornament 12 is calibrated. At the same time, the arrangement of the through holes 11 enhances the three-dimensional effect between the decorations 12 and the cover 1 , and makes the edges of the decorations 12 more rounded, improving the aesthetics of the cover 1 ; the arrangement of the through holes 11 exposes the decorations 12 at the same time. The contact between the corners of the decoration and external objects is reduced, and external forces are prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com