Railway maintenance vehicle

A technology for maintenance vehicles and railways, which is applied to railway inspection vehicles, etc. It can solve the problems of difficult removal of maintenance vehicles, high work intensity, and inconvenience for trains to give way, and achieves the effects of easy removal from the railway, reduced work intensity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

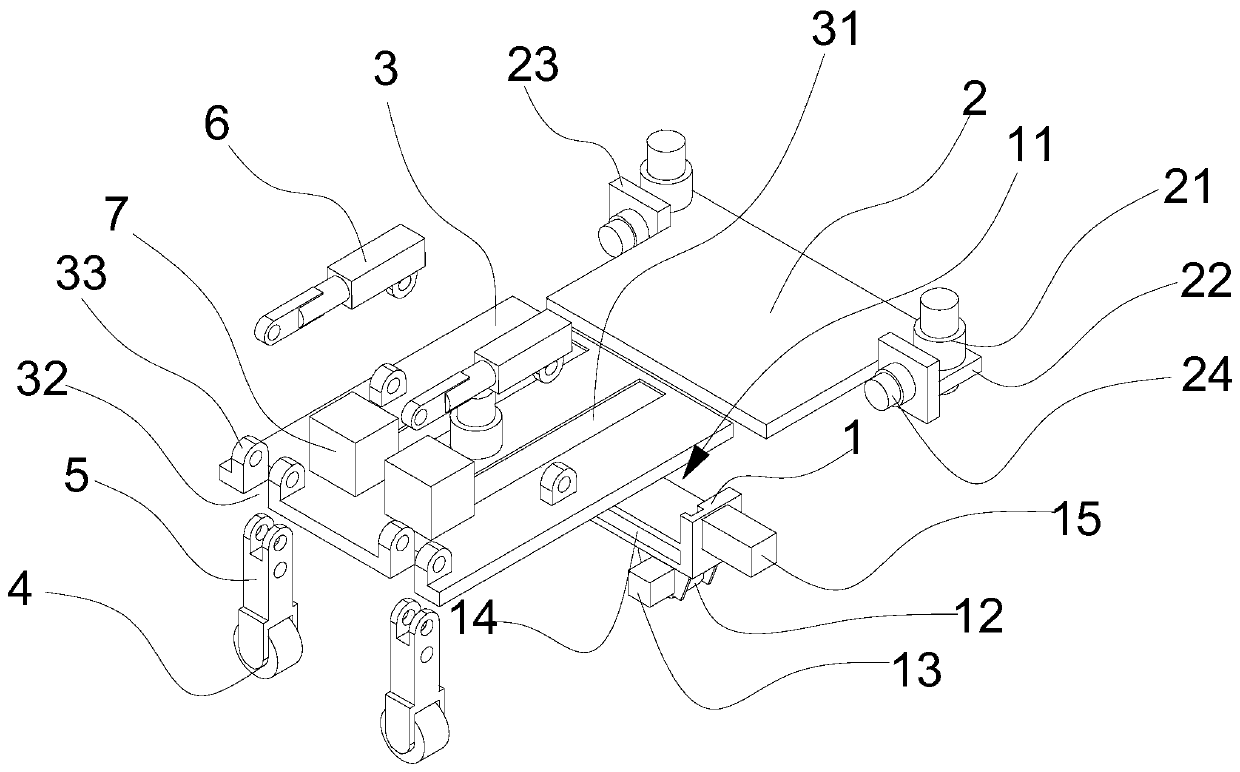

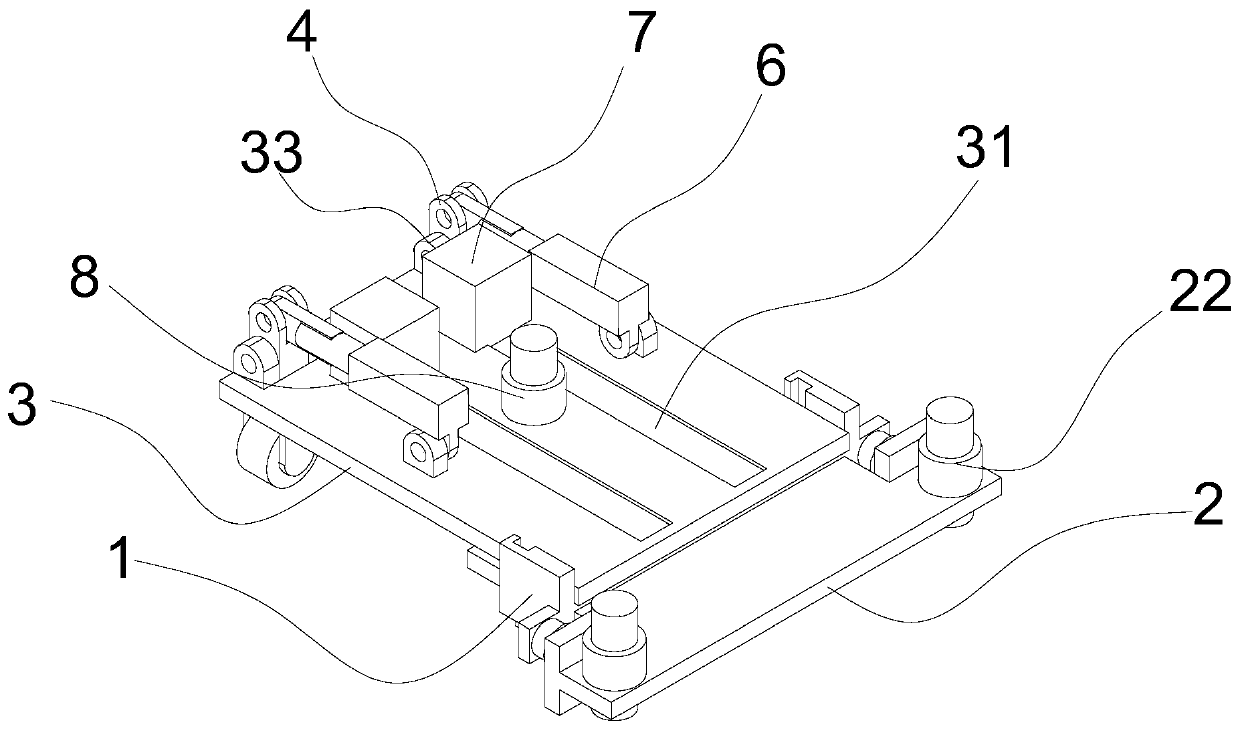

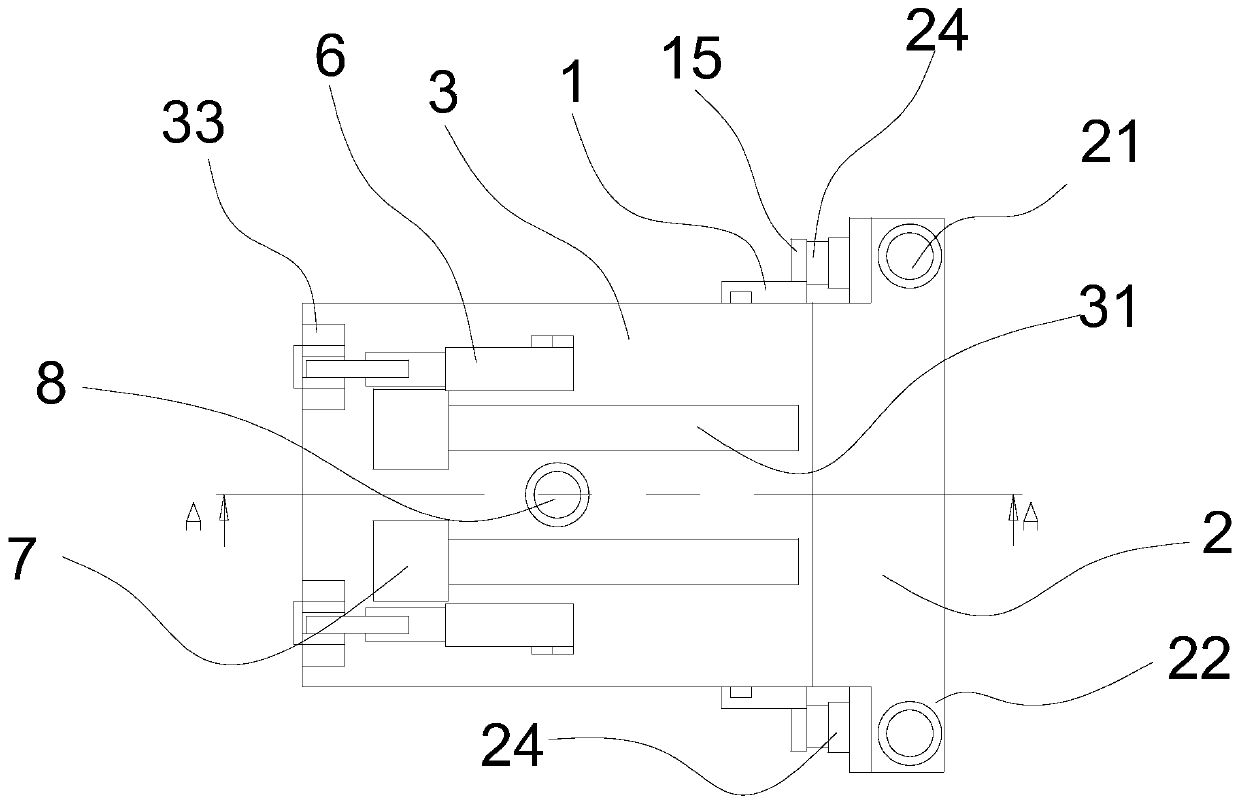

[0031] Such as Figure 1 to Figure 4 As shown, the railway maintenance car of the present invention includes a fixed wheel mounting seat 1, a movable insert plate 2 and a movable support plate 3;

[0032] The fixed wheel mounting base 1 is provided with a chute 11 matching the movable support plate 3; a jack 14 matching the movable board 2 is provided below the chute 11;

[0033] The lower surface of the fixed wheel mounting seat 1 is provided with a roller seat, and a roller 12 is installed on the roller seat; a driving motor 13 for driving the roller 12 to rotate is arranged on the roller seat;

[0034] One end of the movable board 2 is inserted into the jack 14, and the other end is provided with a side ear plate 22; the side ear plate 22 is provided with a first vertical expansion device 21; the expansion and contraction of the first vertical expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com