A fully automatic intelligent assembly model test device system and test method

A technology for assembling models and test devices, which is applied in the field of geotechnical engineering research, can solve the problems of affecting test results and follow-up observations, easily destroying the integrity of model materials, increasing test costs and risks, etc., so as to facilitate production and landfill, The structure is simple and the effect of avoiding the disturbance of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0050] In order to study and simulate different geological conditions and types of underground engineering conditions more safely, quickly and intelligently, it is necessary to develop a fully automatic intelligent assembly model test device system.

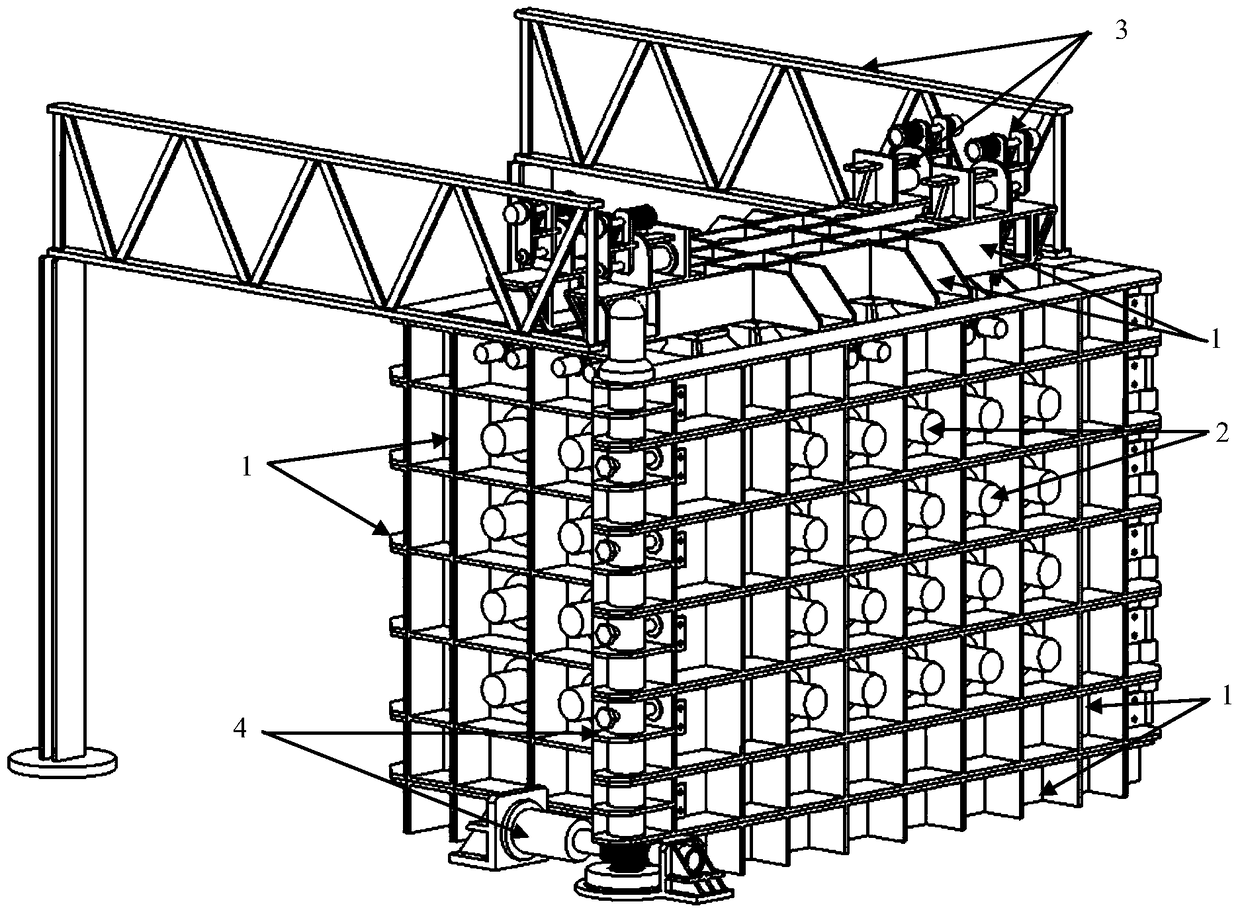

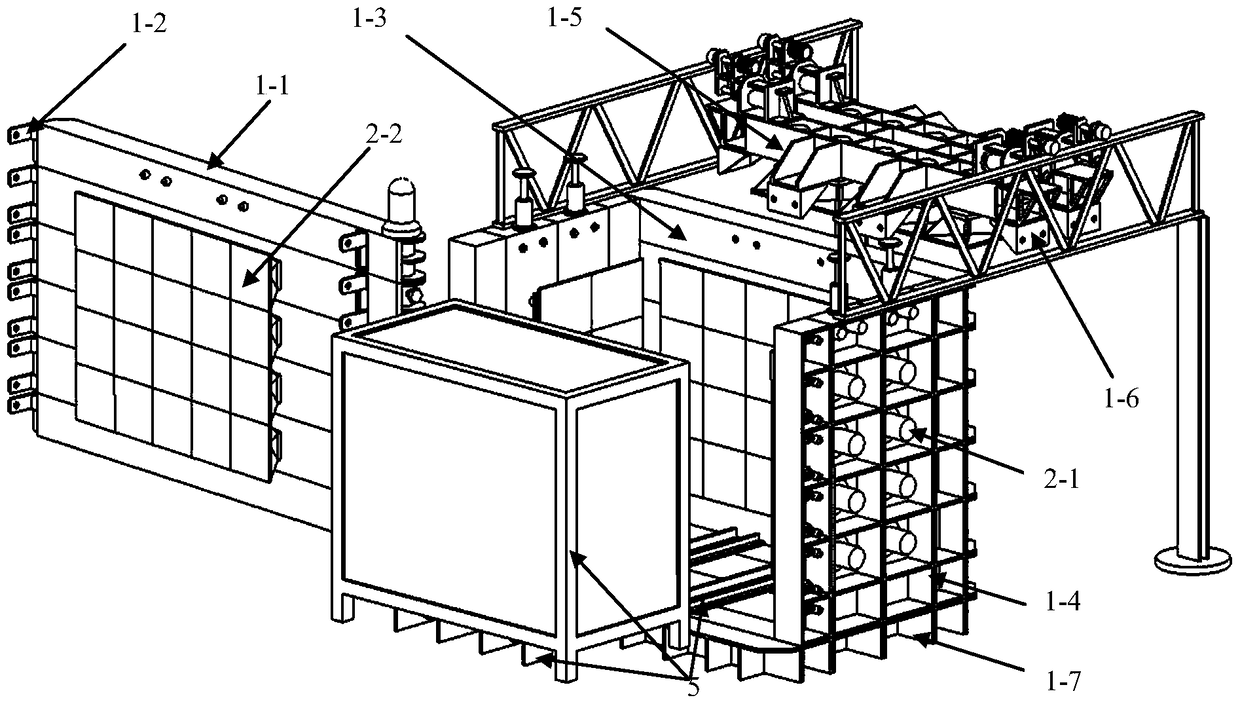

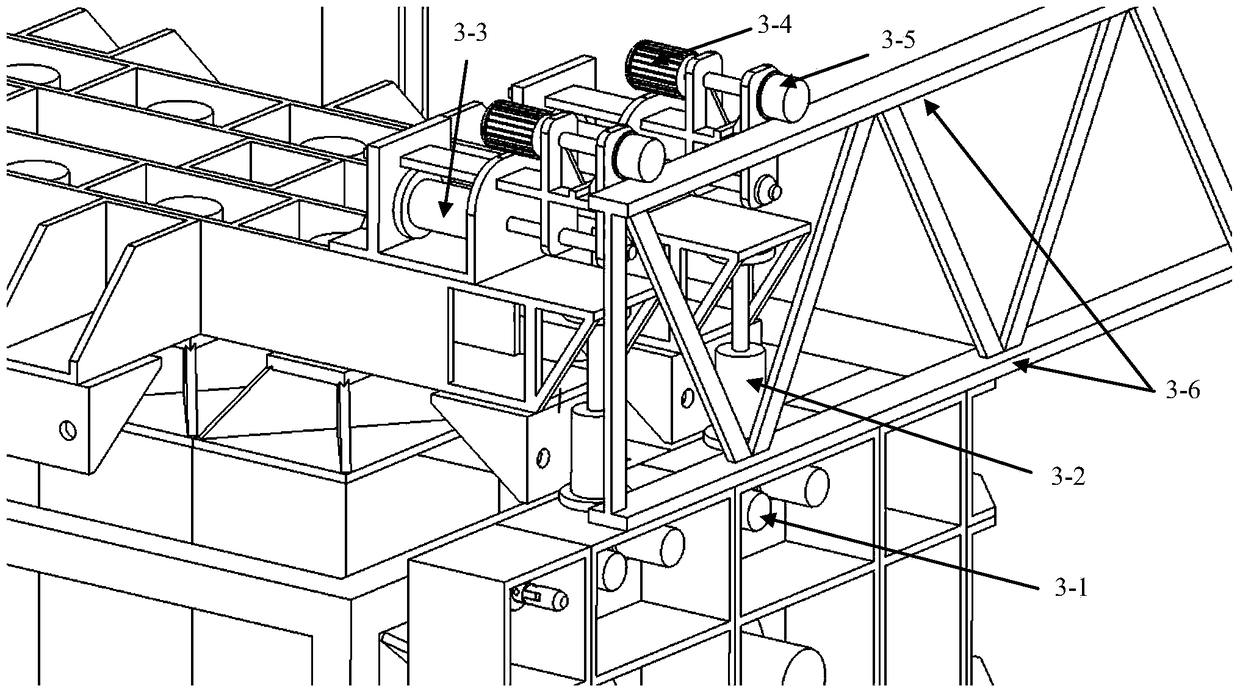

[0051] Such as figure 1 and figure 2 Shown: a fully automatic intelligent assembly model test device system, including model reaction force structure 1, hydraulic loading control system 2, roof beam intelligent lifting-moving system 3, front wall intelligent opening-closing system 4, model removal system 5;

[0052] Such as figure 2 Shown: a model reaction force structure 1 of a fully automatic intelligent assembly model test device system, mainly composed of a front wall reaction beam 1-1, a front wall locking buckle 1-2, a rear wall reaction beam 1-3, left and right walls Reaction beam 1-4, top reaction beam 1-5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com