Automatic rubber roller detecting and packaging device

An automatic detection and pick-up roller technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of large differences in the pick-up roller packaging process, hindering automatic packaging, and packaging accuracy errors, etc. The effect of low cost and high packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

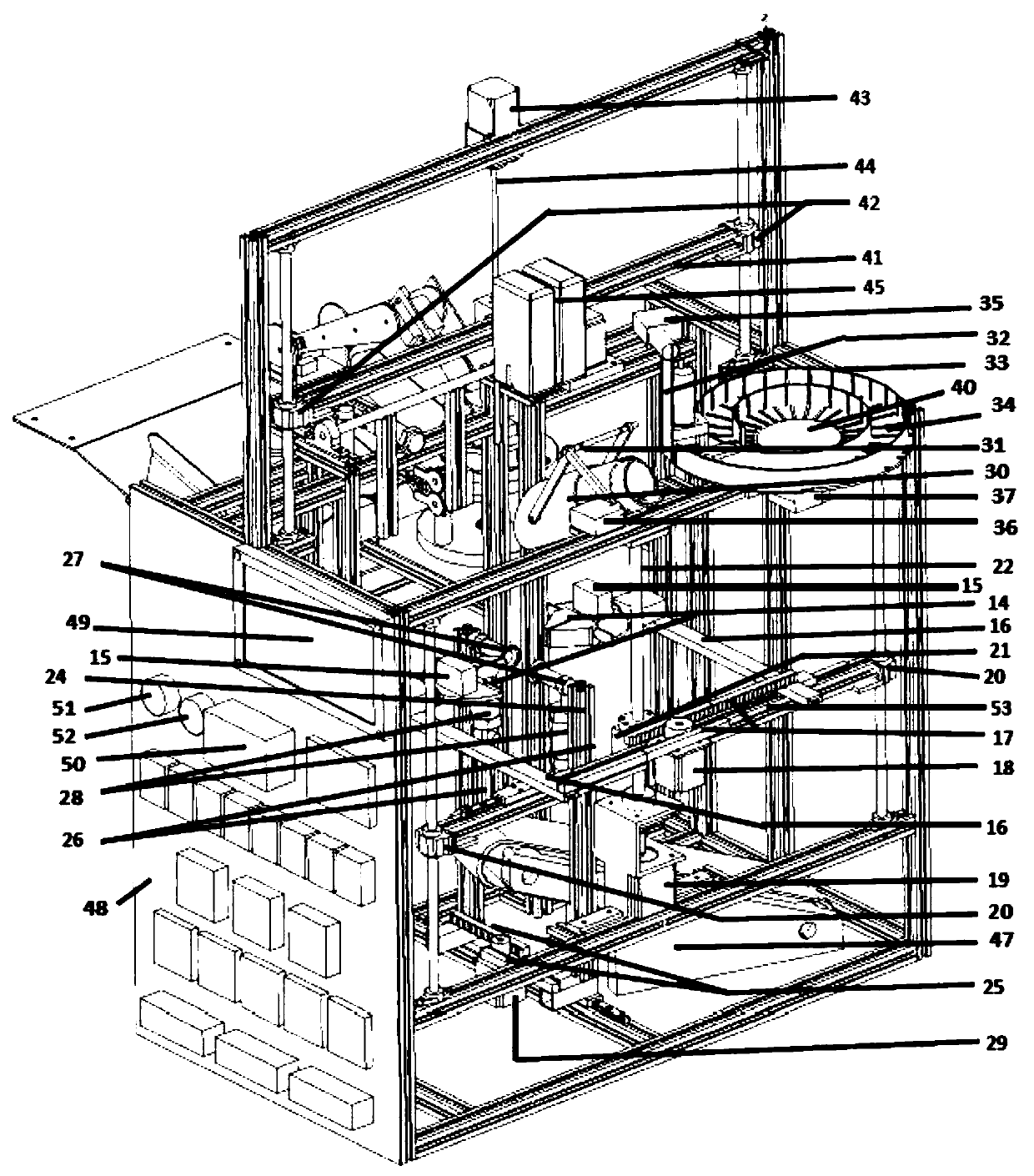

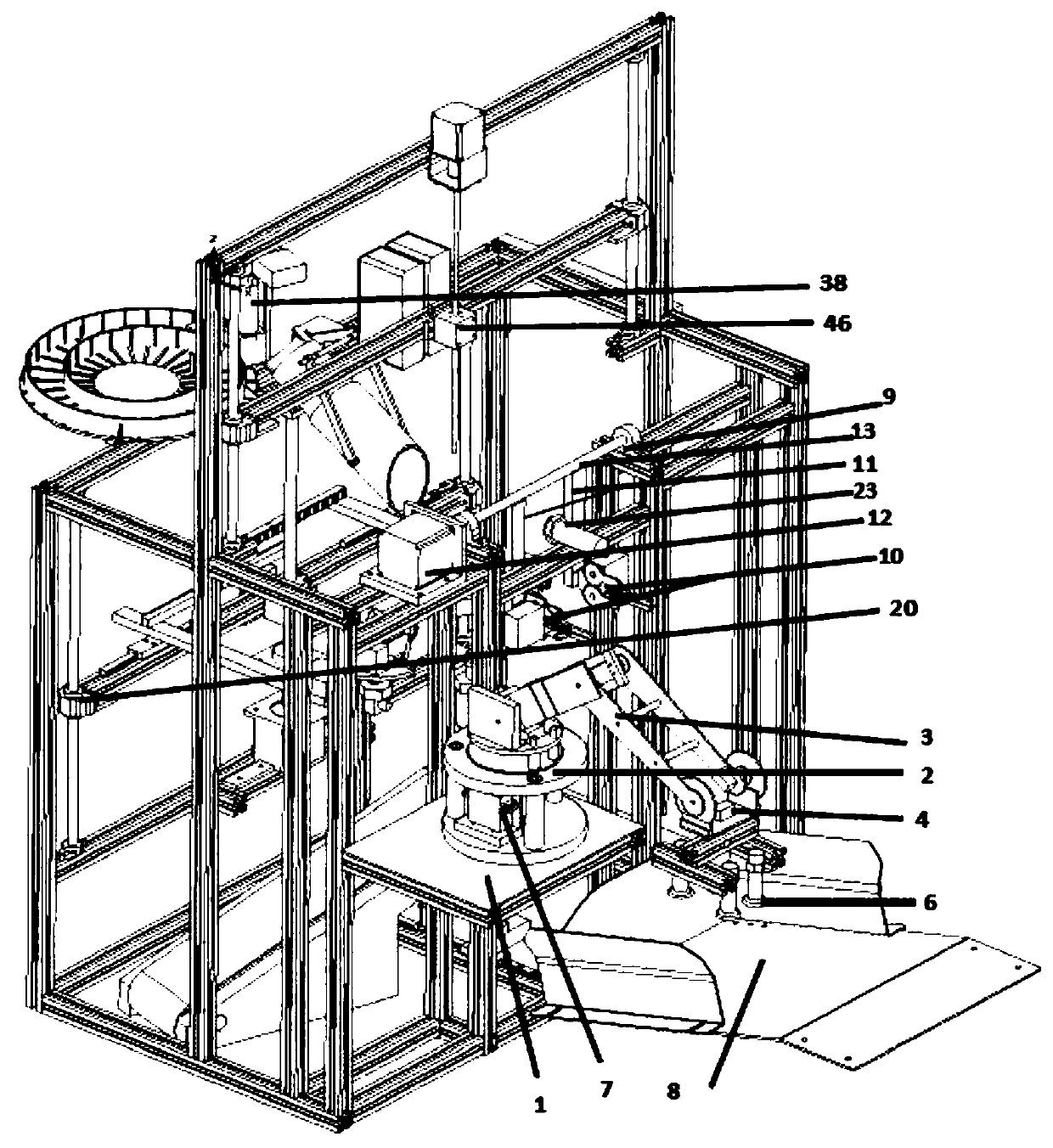

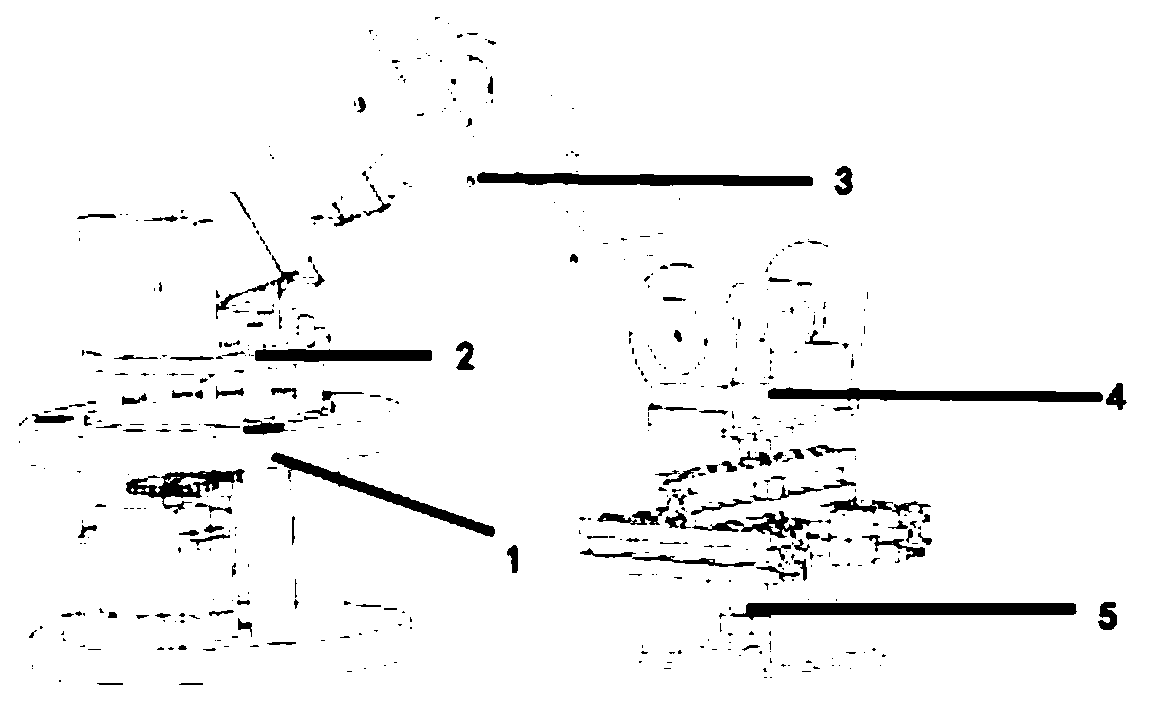

[0026] Please refer to Figure 1-6 ,in, figure 1 It is a structural schematic diagram of a viewing angle of the paper pickup roller automatic detection and packaging device in this embodiment; figure 2 It is a structural schematic diagram of another perspective of the automatic detection and packaging device of the pickup roller in this embodiment; image 3 It is a structural schematic diagram of the bag taking unit in the automatic detection and packaging device of the pickup roller in this embodiment; Figure 4 It is a structural schematic diagram of the flexible channel in the automatic detection and packaging device of the pickup roller in this embodiment; Figure 5 It is a structural schematic diagram of the delivery arm in the automatic detection and packaging device of the pickup roller in this embodiment; Image 6 It is a bottom view of the delivery arm in the pickup roller automatic detection and packaging device of this embodiment.

[0027] The automatic detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com