All-in-one machine for cleaning, crushing and compacting deciduous leaves

An all-in-one machine and leaf-falling technology, which is applied in the direction of presses, material forming presses, solid separation, etc., can solve the problems of collection, storage and transportation, damage to operating equipment, and easy to be blocked by foreign objects, etc., to achieve high efficiency and crushing effect Good, speed up the effect of subsequent leaf fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

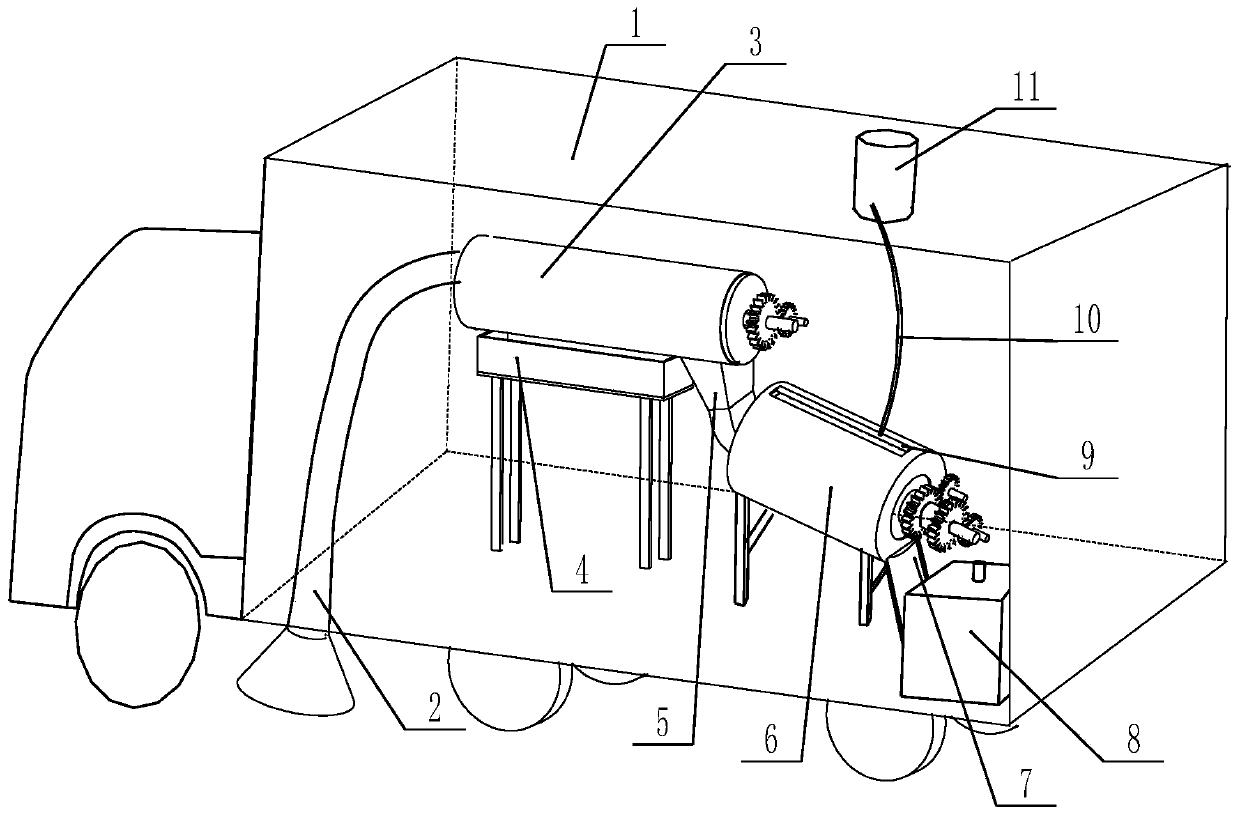

[0031] Such as Figure 1-6 As shown, a fallen leaf cleaning, pulverizing and compacting integrated machine according to the present invention includes a car body 1, a cleaning device 2, a filtering device 3, a filter residue collecting device 4, a crushing device 6, a spraying device and a briquetting device 8;

[0032] There is a fan in the cleaning device, and the rotation of the fan creates a negative pressure to suck the fallen leaves from the suction pipe into the filter cavity. The entrance of the suction pipe is a bell mouth, which can increase the adsorption area.

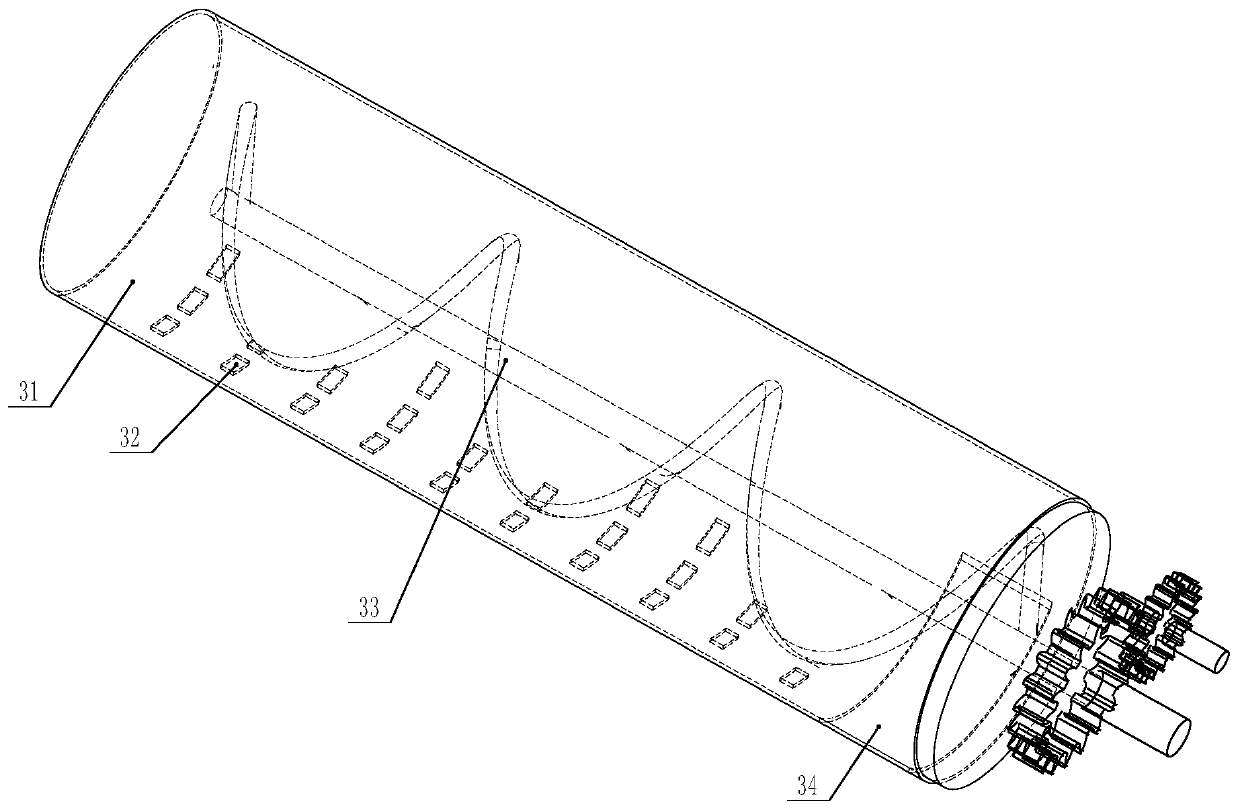

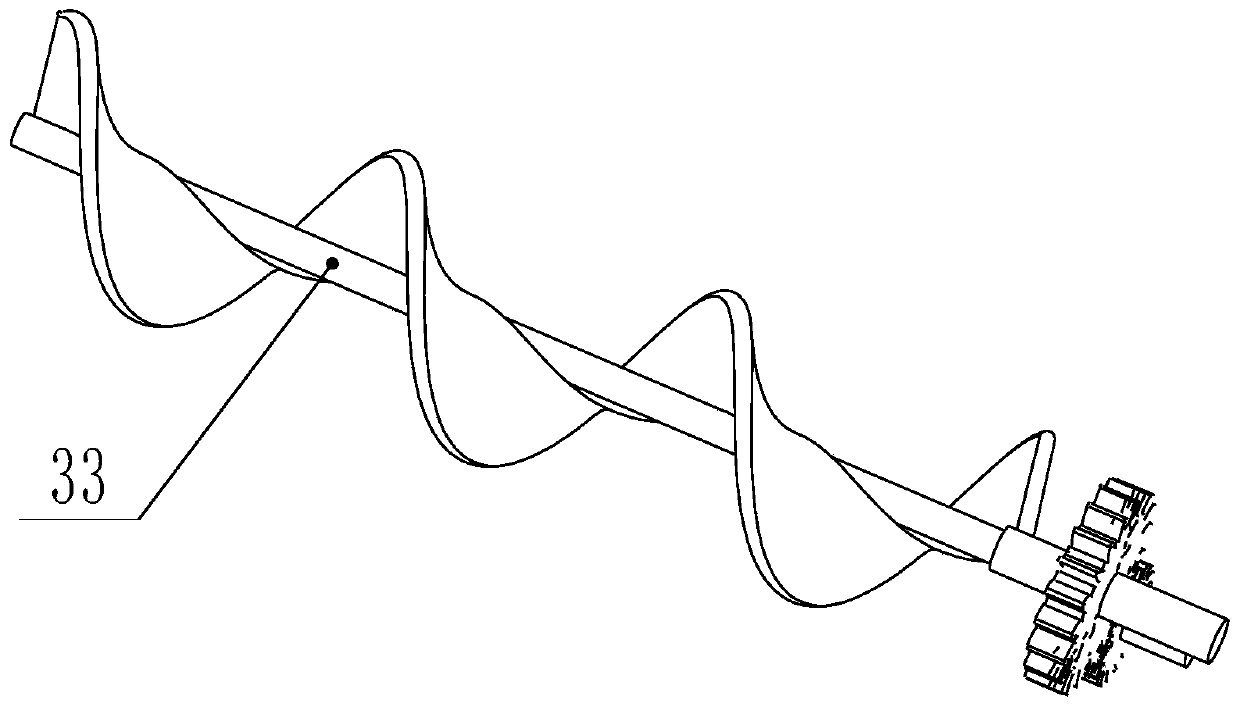

[0033] The filter device comprises a filter cartridge 31, a screw shaft 33 and a driving device. The screw shaft is installed in the filter cartridge, and one end of the screw shaft is connected to the drive device; the filter cartridge is fixed horizontally in the vehicle body, and the front end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com