Automatic vending machine with function of automatic food heating

A vending machine and automatic heating technology, which is applied in the direction of coin-operated equipment, instruments, coin-free or similar appliances for distributing discrete items, etc. It can solve the problems of reducing the shopping experience of consumers, simple heating methods, and unsuccessful heating, etc. problem, to achieve rapid and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

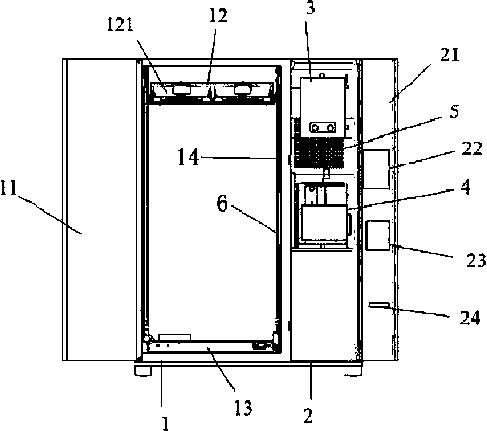

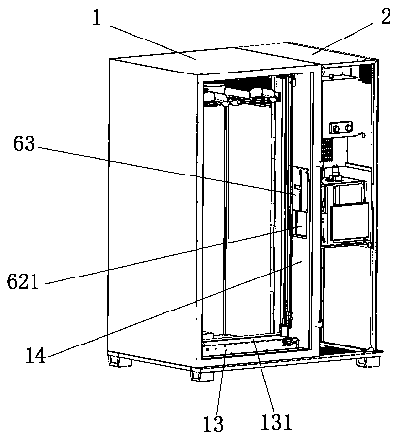

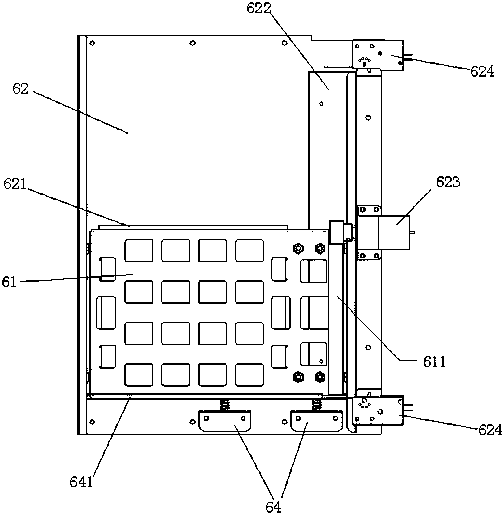

[0035] Such as figure 1 , 2 A kind of automatic heating food automatic vending machine shown in 15, comprises container 1 and heating cabinet 2, is provided with thermal insulation material around container 1 body, is provided with the insulation door between described container 1 and heating cabinet 2 6, the goods in the container 1 can enter the heating cabinet 2 through the inlet 621 provided on the heat preservation door 6, and the box wall 14 at the upper end of the inlet 621 is provided with a The bottom plate 631 is fixed to the push mechanism 63, the front of the container 1 is provided with a container door 11, the front of the heating cabinet 2 is provided with a heating cabinet door 21, and the heating cabinet door 21 is provided with a human-machine interaction panel 22, the human-machine The lower end of the interaction panel 22 is provided with a pick-up port 23, the lower end of the pick-up port 23 is provided with a chopsticks box installation port 24, and the...

Embodiment 2

[0042] In this example, if Figure 5 , 6 The processing device 4 shown can also have the following structure, the processing device 4 includes a water injection mechanism 41 and a processing box 42, the water injection mechanism 41 is arranged in the processing box 42, and the water injection mechanism 41 includes a wire Rod power motor 411, screw mandrel 412, water injection platform 413; Described water injection platform 413 is provided with water injection pipe 417 and linear bearing 418, and described processing box 42 upper end is provided with the through hole 44 that is convenient to water injection pipe 417 tops to pass through, so The front part of the water injection platform 413 is provided with a photoelectric switch 419. When the photoelectric switch detects the goods, the control system drives the screw power motor, so that the water injection pipe 417 moves downward to heat the food box. This embodiment is different from the first embodiment. The advantage is ...

Embodiment 3

[0046] Such as Figure 11 , 12 , 13 and 14, a kind of automatic heating food vending machine, the heating device 3 is a microwave oven heating mechanism 7 including a microwave oven box 71 and a lifting platform 72, the opening of the microwave oven box 71 faces downward, and the microwave oven box Both sides of body 71 back are provided with fixing device 79, and described lift platform 72 is L-shaped base plate, and lift platform 72 bottom panels are adapted to the size of opening of microwave oven cabinet 71, and lift platform 72 can completely seal microwave oven box opening, has guaranteed like this For the tightness of the inner space of the microwave oven, grooves 722 are arranged on both sides of the vertical panel 724, and the vertical panel 724 is installed on the fixing device 79, and the fixing device 79 is provided with a pulley 711, and the pulley 711 is embedded in the groove In 722, the upright panel is installed on a set of fixing devices. There are a series ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com