EL detection method for crystalline silicon photovoltaic module of photovoltaic power station

A photovoltaic power station and photovoltaic module technology, applied in photovoltaic power generation, photovoltaic system monitoring, photovoltaic modules, etc., can solve problems such as inability to obtain process parameters, low detection efficiency, and unmonitored product quality, so as to improve detection efficiency , Speed up the detection speed, improve the clarity and effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

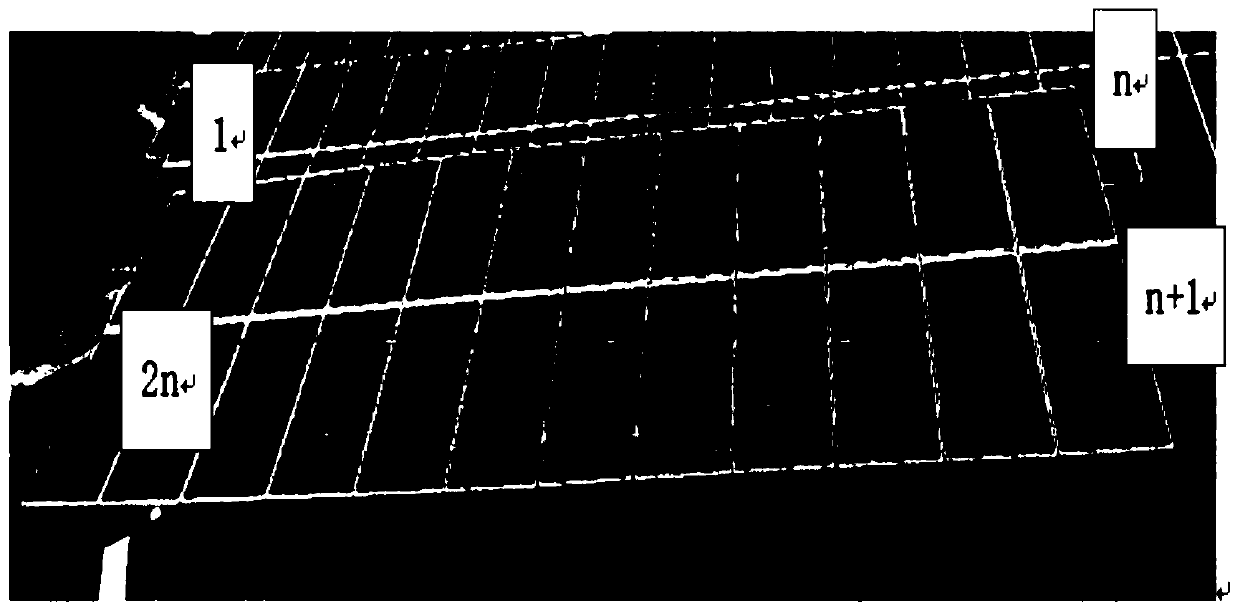

[0037]The method for EL detection (also known as electroluminescence detection) of crystalline silicon photovoltaic modules in a photovoltaic power station is characterized in that it includes the following steps: assembling EL detection equipment, copying the serial number of the component to be tested, and powering on the component on the bracket after installation or Power on the delivered components, parameter setting steps, adjust the position of the infrared camera, retrieve the test components, take images, and record defects. Copying the serial number of the component to be tested includes the following steps: assigning a positioning number to the component, any component adopts the frame number in the field plus the positioning number, and the positioning number is from the upper row on the front of the frame component from left to right 1→n, and then by The lower row of the frame is numbered sequentially from right to left n+1→2n. The assembling of the EL detection e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com