Drive power transmission mechanism and electric lock using same

A technology of transmission mechanism and driving force, applied in the field of driving force transmission mechanism and electronic lock, can solve the problems of complicated structure, and achieve the effect of simplifying the overall structure, simple structure and large degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

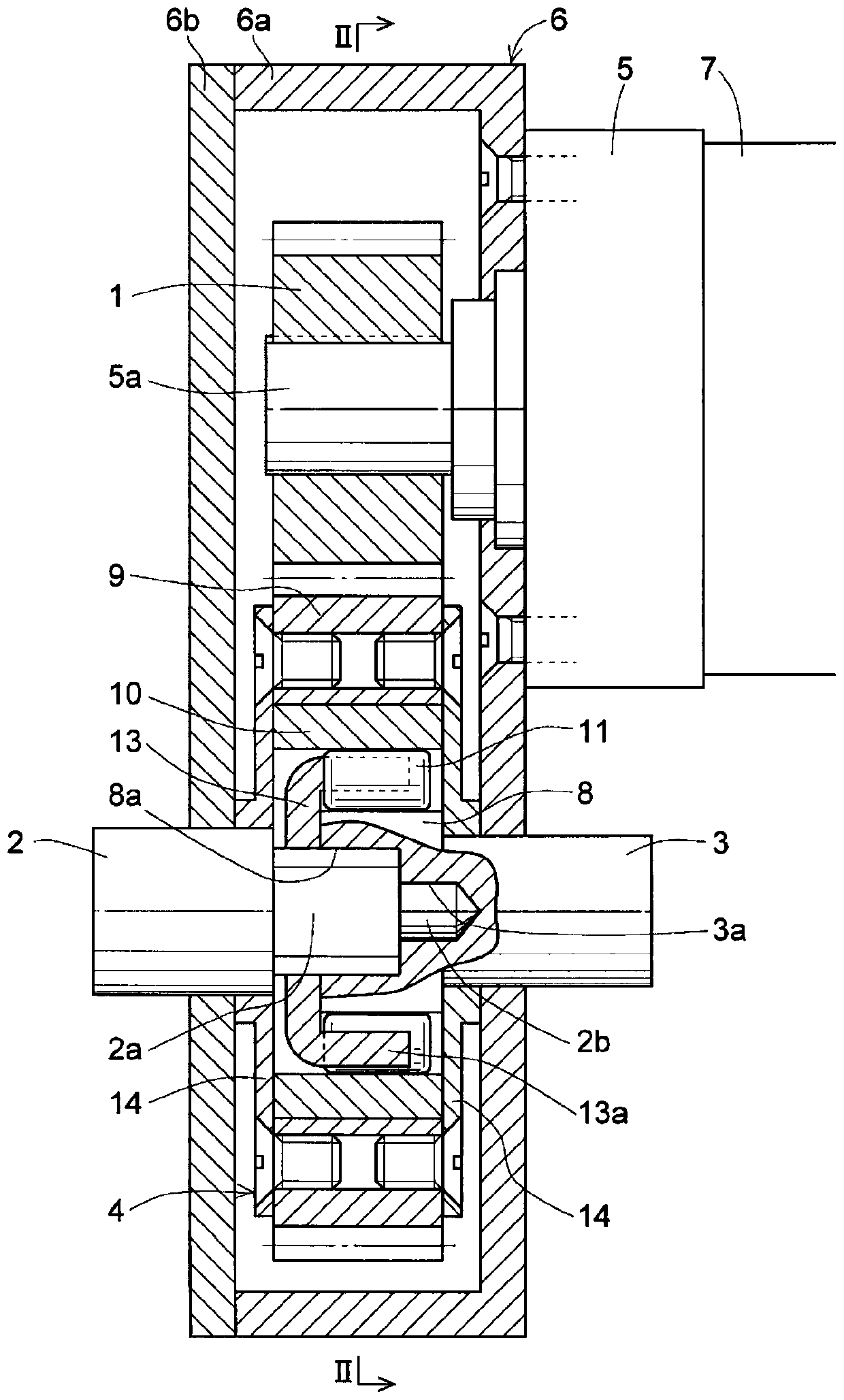

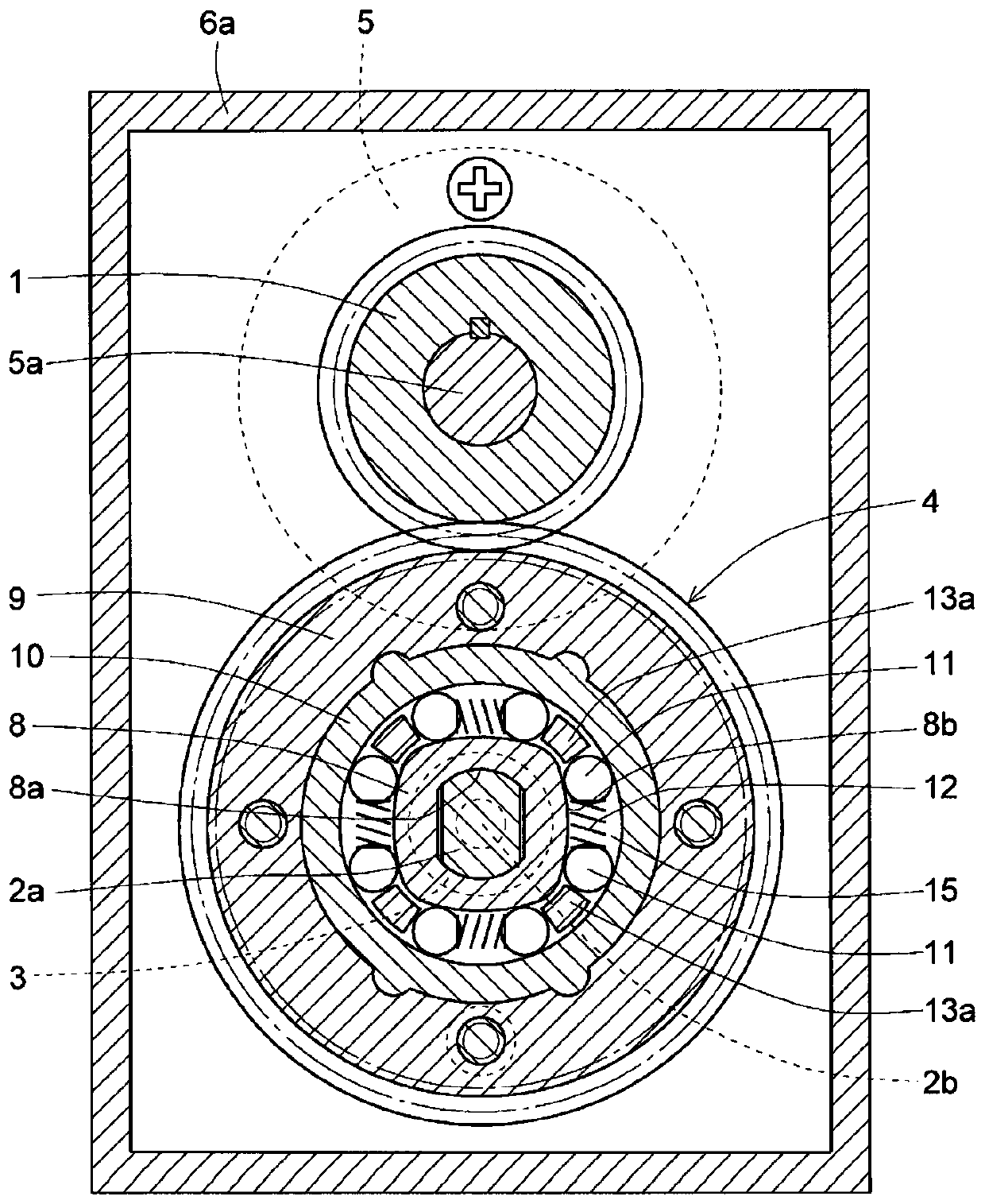

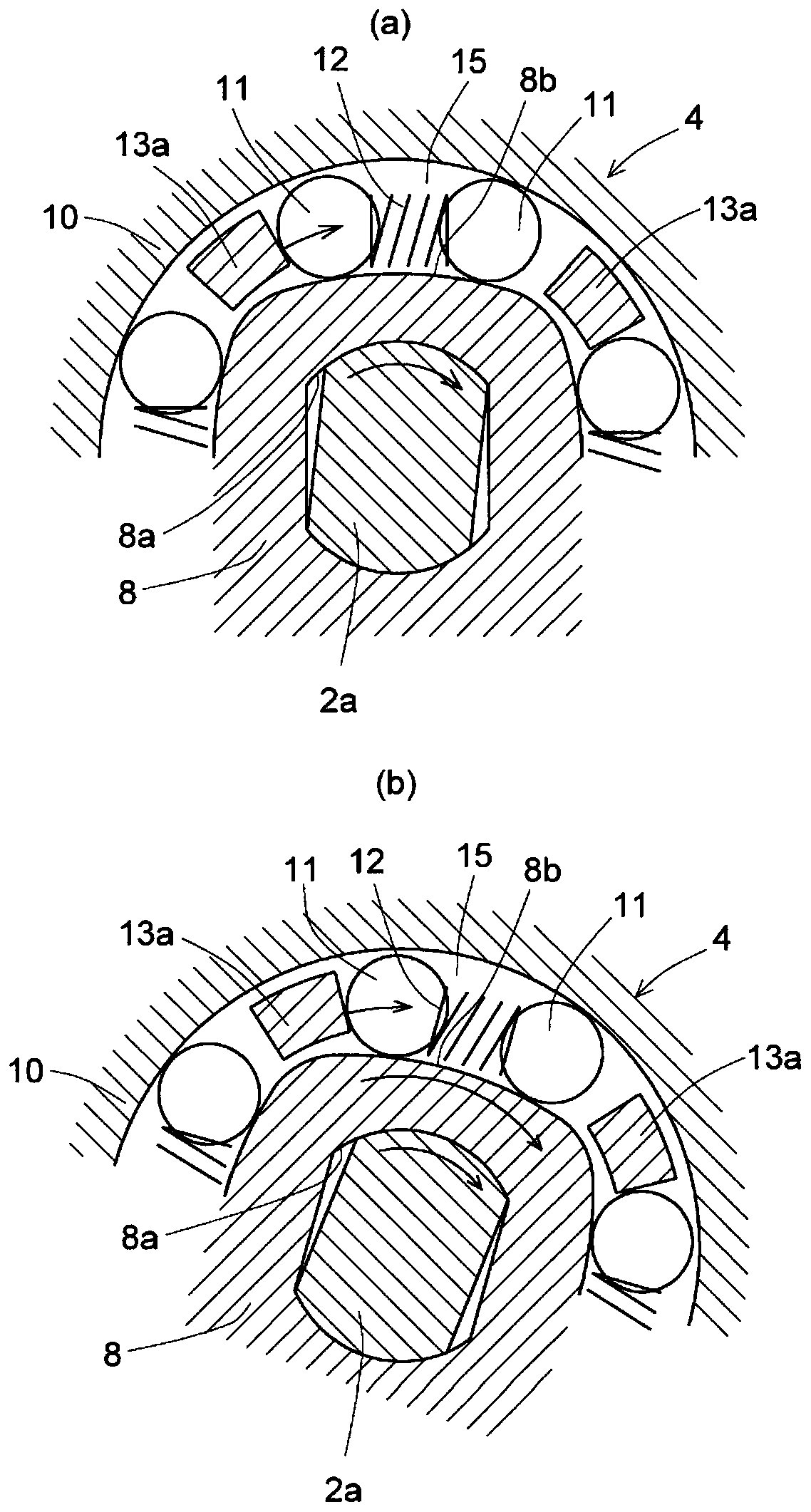

[0024] Embodiments of the present invention will be described below based on the drawings. Figure 1 to Figure 3 shows the first embodiment. Such as figure 1 and figure 2 As shown, the driving force transmission mechanism has: an electric input gear 1 as a first input part; a manual input shaft 2 as a second input part; an output shaft 3 as an output part; An input switching clutch 4 that transmits the rotational driving force of any one of the manual inputs to the manual input shaft 2 to the output shaft 3 ; and a speed reducer 5 provided on the input side of the electric input gear 1 . The electric input gear 1, the inner end portions of the manual input shaft 2 and the output shaft 3, and the input switching clutch 4 are housed in a case (fixed member) that closes the opening on one side of the rectangular box portion 6a with the cover portion 6b. )6. In addition, the speed reducer 5 has no self-locking function, and constitutes a motor with a speed reducer together wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com