Clockwork component, clockwork, timepiece, and method for manufacturing a clockwork component of said type

A technology for clock movement and parts, applied in the field of manufacturing such clock movement parts, can solve the problems of complex mechanical properties, inability to achieve high mechanical precision, and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the figures, the same reference numerals designate the same or similar elements.

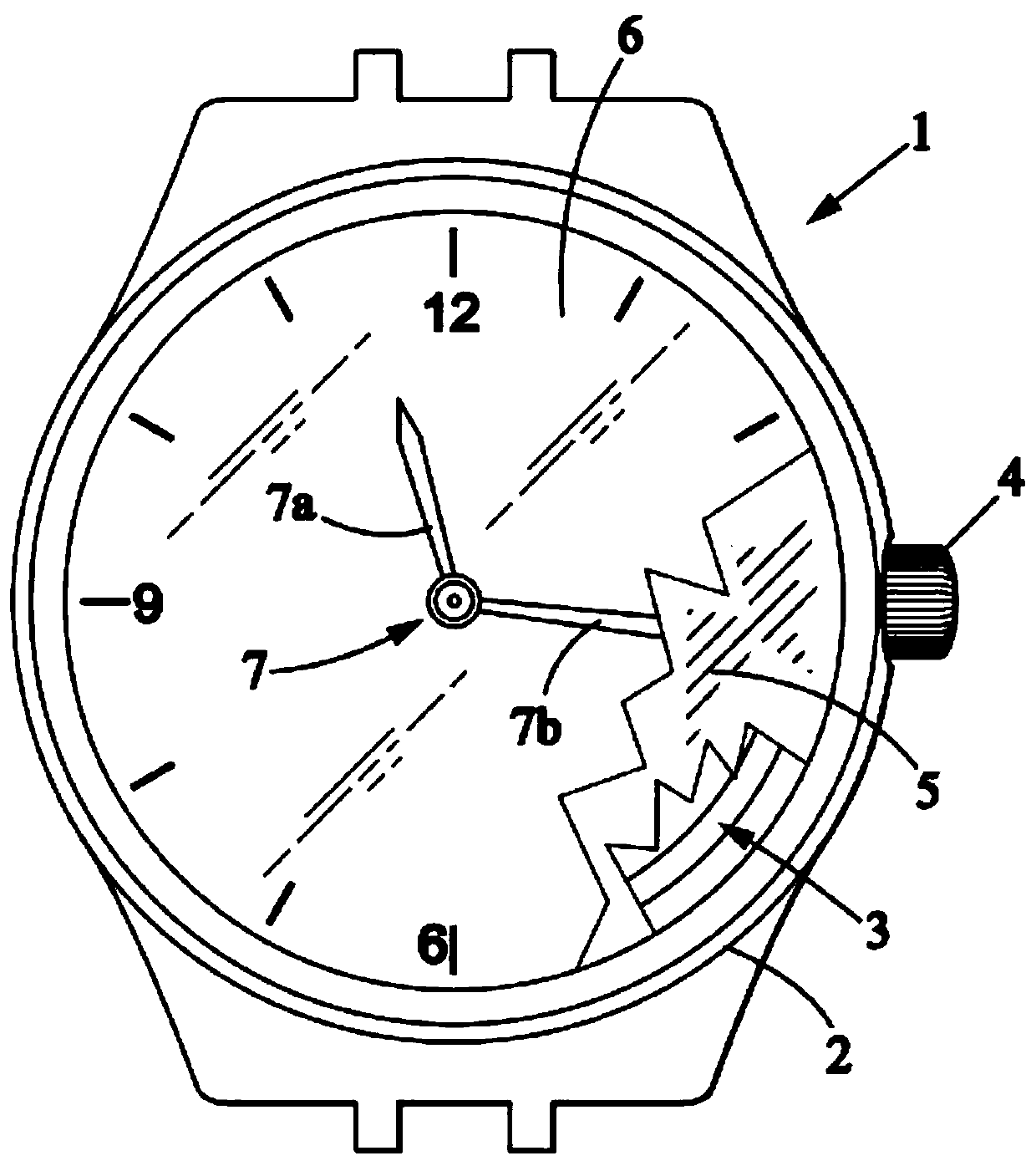

[0046] figure 1 A timepiece 1 such as a wrist watch is shown comprising:

[0047] - Shell 2,

[0048] - a timepiece movement 3 contained in a case 2,

[0049] - in general, the winding mechanism 4,

[0050] - dial 5,

[0051] - the crystal 6 covering the dial 5,

[0052] - A time indicator 7 , for example comprising two hands 7 a , 7 b , respectively hour and minute, arranged between the crystal 6 and the dial 5 , driven by the timepiece movement 3 .

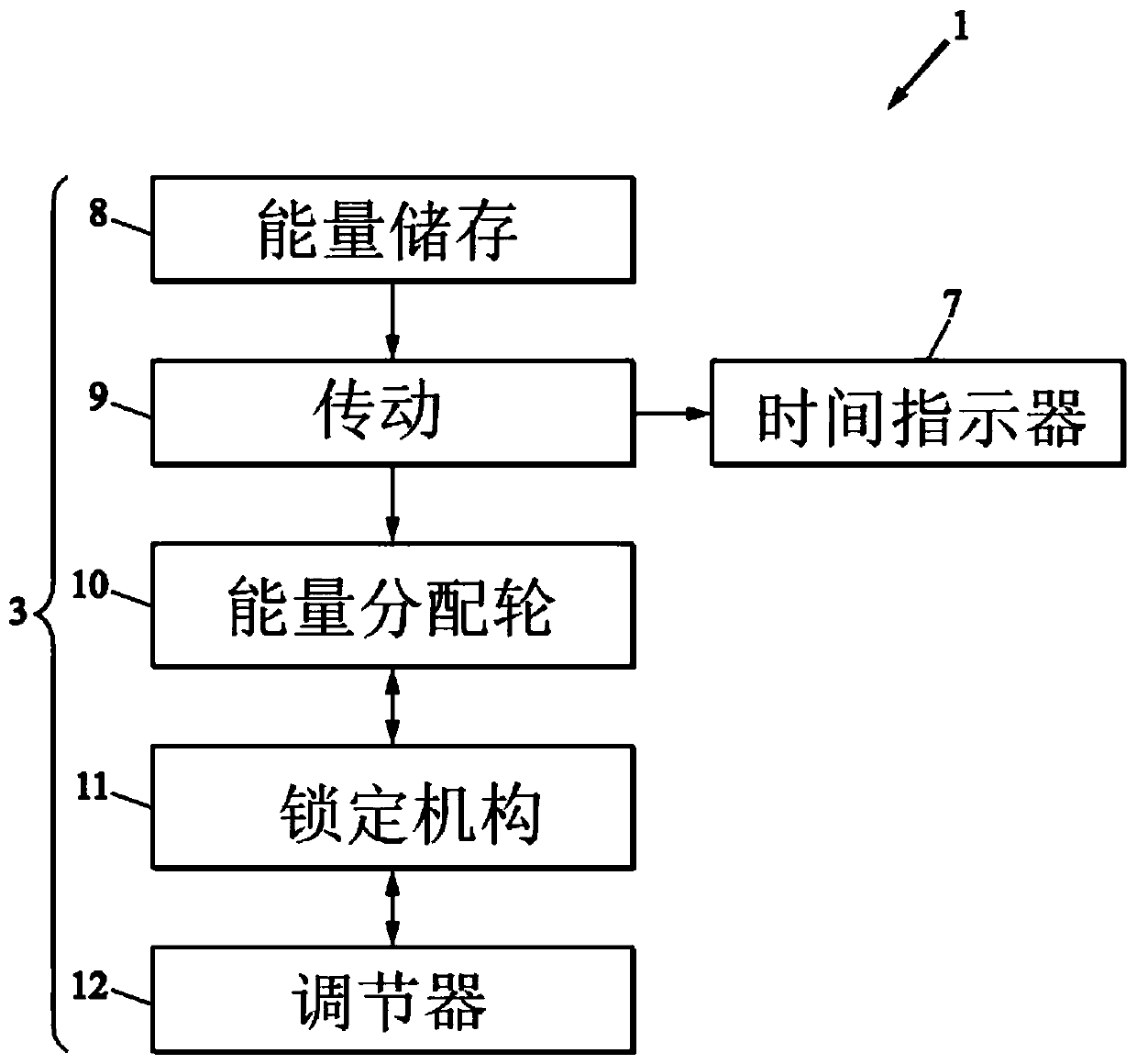

[0053] Such as figure 2 As schematically shown in, for example, the timepiece movement 3 may include:

[0054] - means 8 for storing mechanical energy, usually a mainspring,

[0055] - a mechanical transmission 9 driven by a device 8 for storing mechanical energy,

[0056] - the aforementioned time indicator 7,

[0057] - energy distributing wheel 10 (for example, the escapement wheel of a Swiss anchor escapement or similar), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com