Energy storage compressing type garbage bin

A trash can, compression technology, applied in the field of trash cans, can solve the problems of small weight, increasing the workload of sanitation workers, increasing the consumption of garbage bags, and the frequency of family members throwing garbage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

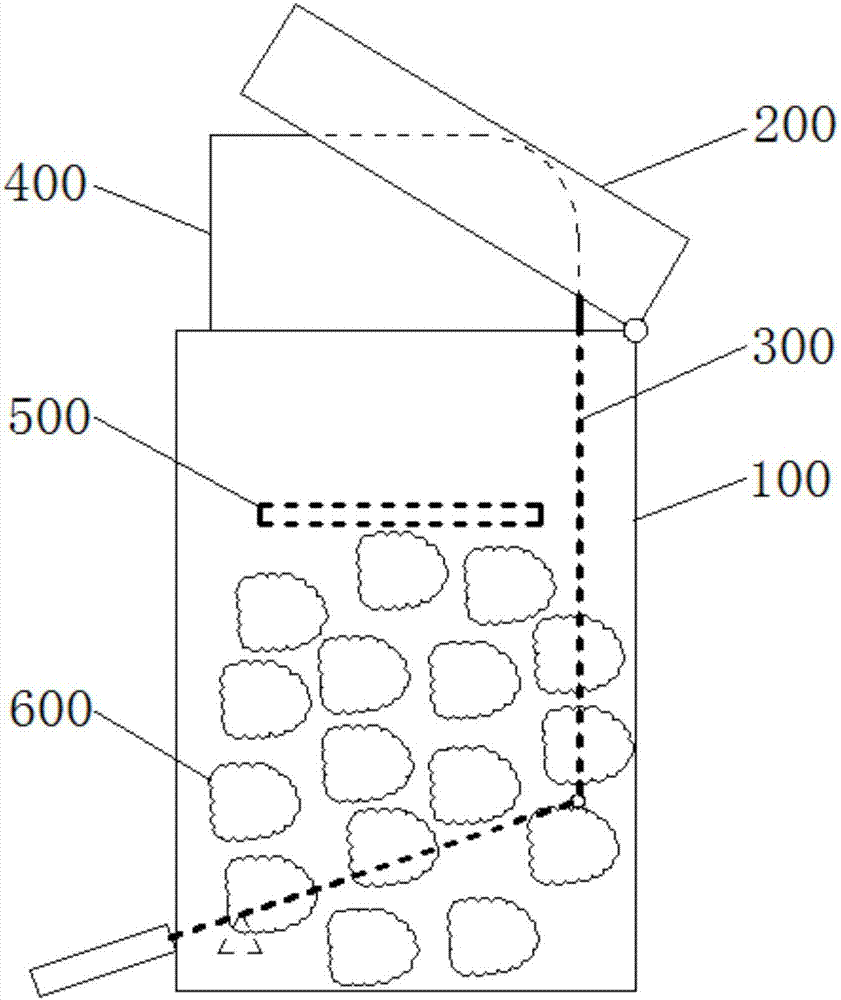

[0022] Embodiment 1: a kind of energy-storage compression trash can, its structure is as follows figure 1 As shown, it includes a bucket body 100, a bucket lid 200 and a bucket lid opening mechanism 300 that drives the bucket lid 200 to open. The bucket body 100 is provided with a casing 400 and an energy storage compression mechanism 500 composed of an energy storage mechanism and a compression mechanism. , the energy storage compression mechanism 500 is packaged in the casing 400;

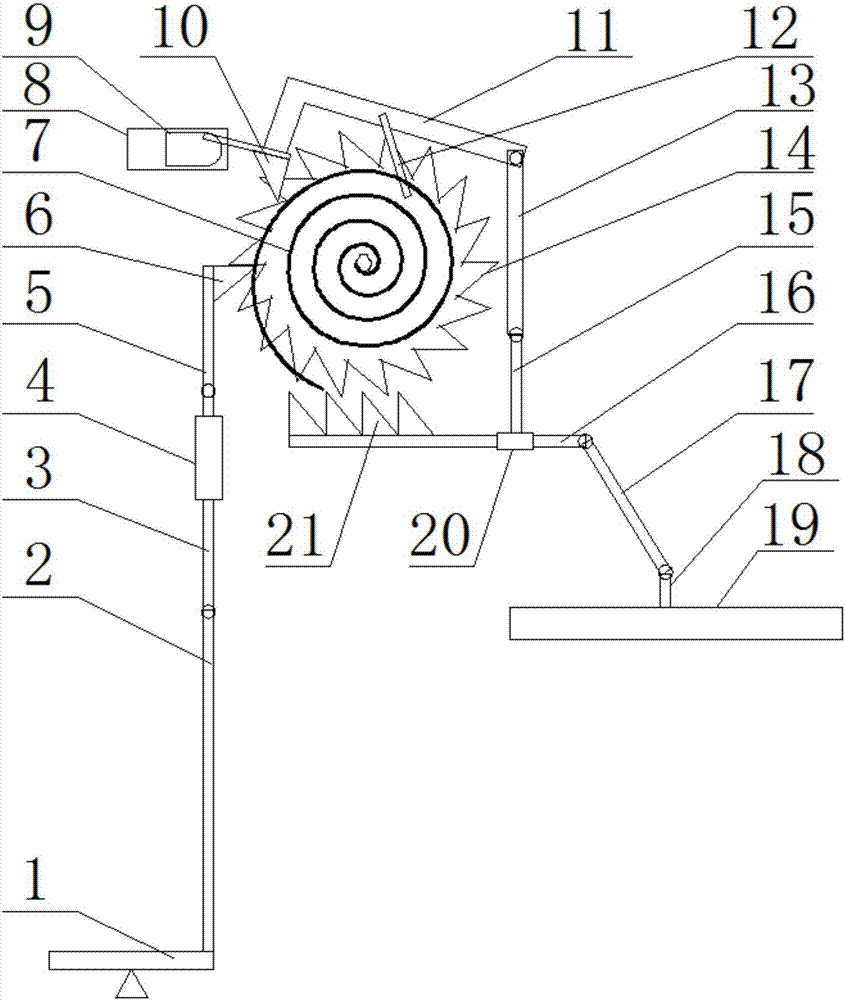

[0023] see figure 2, the energy storage mechanism includes a first linkage mechanism, a first guide sleeve 4, an active pawl 6, a ratchet wheel 14, a mainspring 7, a baffle plate 12, a non-return pawl 10, a slider 9, a chute 8, a first The two linkages and the second guide sleeve 20, the first linkage and the second linkage are all three linkages composed of active rods 2, 11, intermediate rods 3, 13 and driven rods 5, 15 sequentially hinged mechanism, the active rod 2 of the first link mechan...

Embodiment 2

[0024] Embodiment 2: a kind of energy-storage compression trash can, its structure is as follows figure 1 As shown, it includes a bucket body 100, a bucket lid 200 and a bucket lid opening mechanism 300 that drives the bucket lid 200 to open. The bucket body 100 is provided with a casing 400 and an energy storage compression mechanism 500 composed of an energy storage mechanism and a compression mechanism. , the energy storage compression mechanism 500 is packaged in the casing 400;

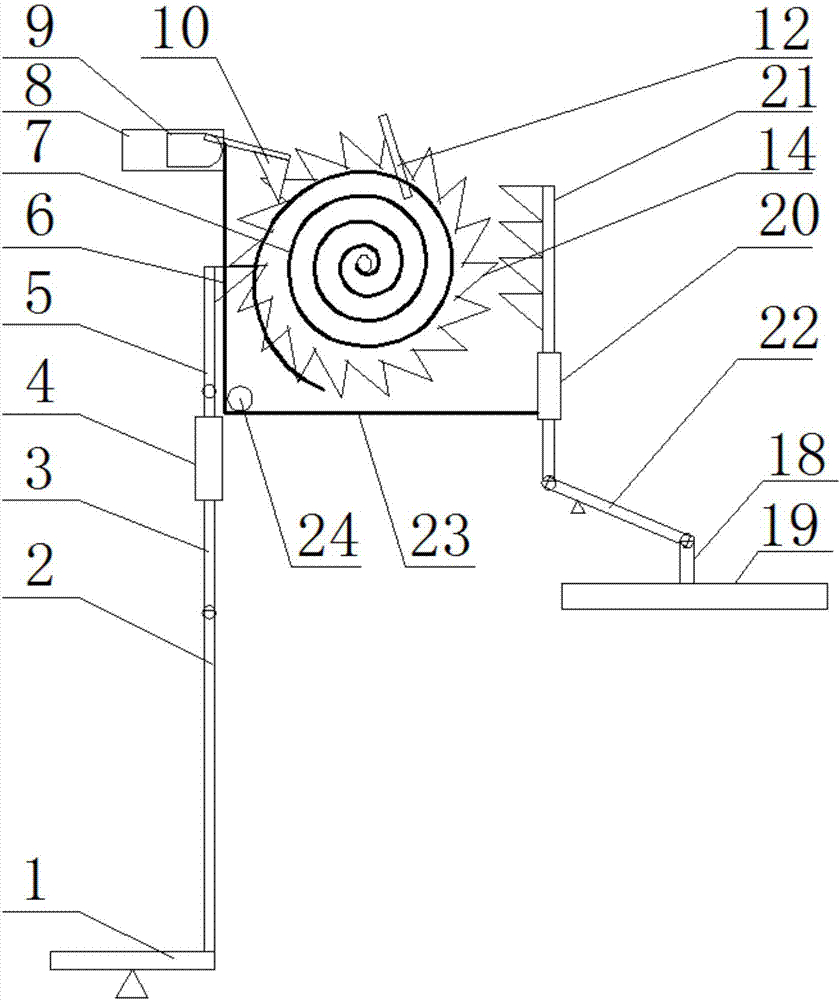

[0025] see image 3 , the energy storage mechanism includes a three-bar linkage mechanism, a first guide sleeve 4, an active pawl 6, a ratchet wheel 14, a mainspring 7, a baffle plate 12, a non-return pawl 10, a slider 9, a chute 8, and a traction mechanism And the second guide sleeve 20, the three-bar linkage mechanism is composed of the active rod 2, the intermediate rod 3 and the driven rod 5 sequentially hinged, the active rod 2 is hinged with the pedal 1 of the lid opening mechanism 300, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com