A reciprocating wire cut electrical discharge machining tool

A technology of wire electric discharge and cutting machine tools, which is applied in the direction of electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problems of easy pinch-off electrode wires of workpieces, etc., achieve simple structure, improve production efficiency, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

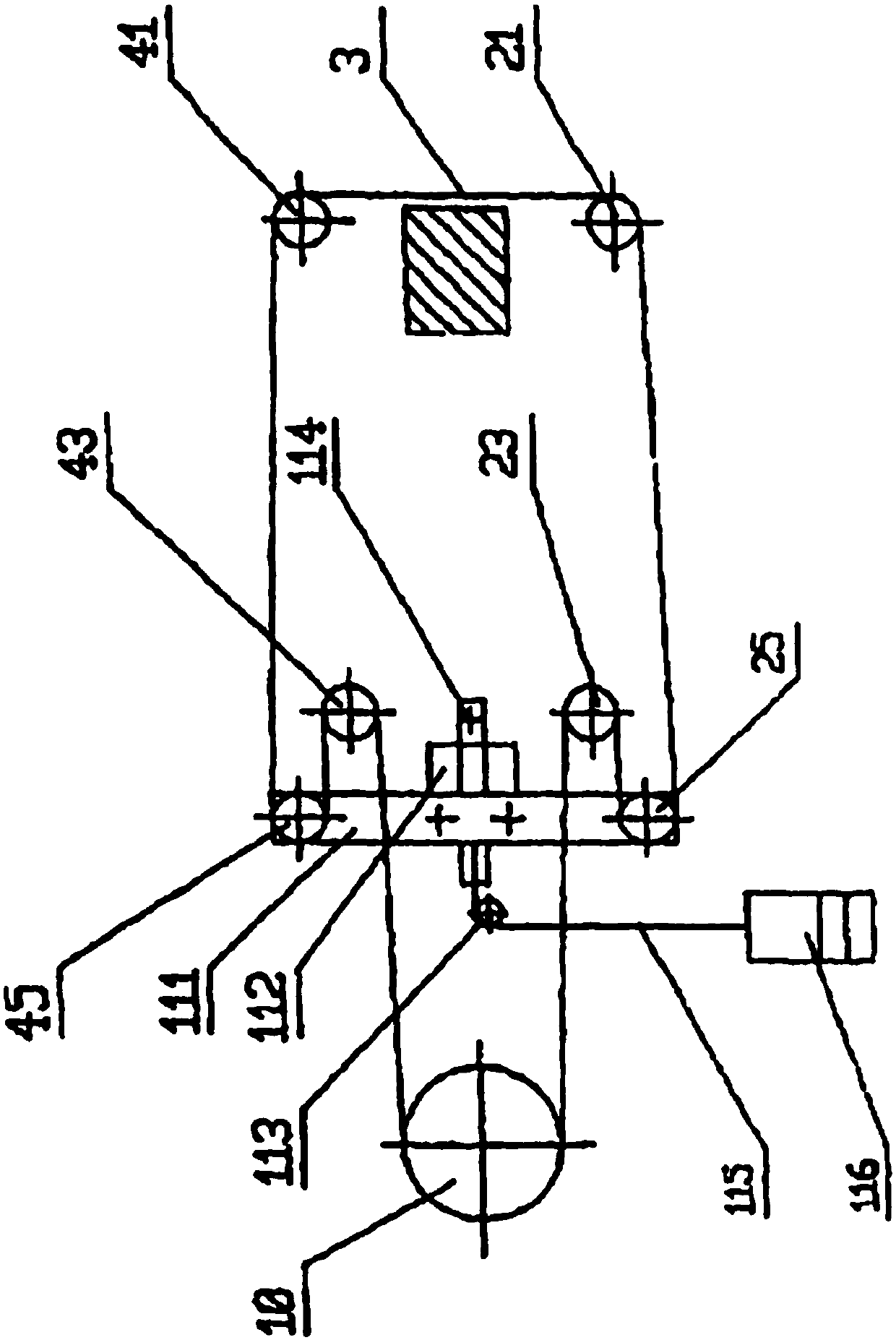

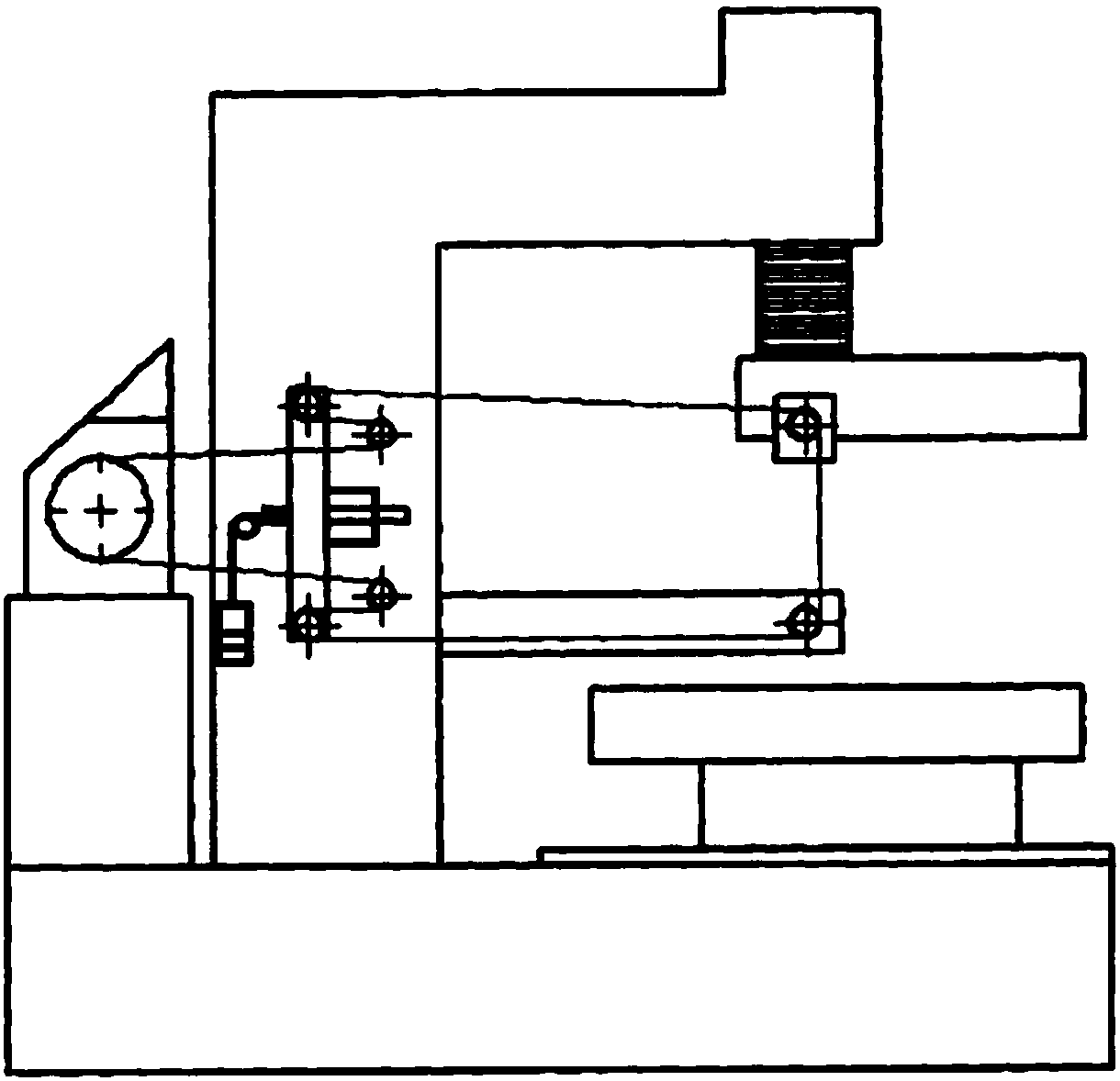

[0025] A reciprocating wire electric discharge machine tool, comprising a wire storage mechanism 400 and a wire transport mechanism 500, the wire storage mechanism 400 includes a wire storage barrel 402, and the wire transport mechanism 500 includes a first capstan 505, a second capstan 506 and a second capstan A guide wheel 525, in the space Cartesian coordinate system with X, Y, Z axis as the coordinate axis, the axis of the first guide wheel 505 and the axis of the second guide wheel 506 are all parallel to the Y axis, the electrode wire 600 can be moved from the storage The wire barrel 402 starts to go around the first guide wheel 525, the first capstan wheel 505 and the second capstan whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com