Substrate processing apparatus and method

A technology of a substrate processing device and a substrate processing method, which is applied in the directions of grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems such as difficulty in accurately determining the end point of grinding of the substrate W, difficulty, insufficiency, etc., so as to shorten the processing time, The effect of improving the grinding quality and simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, but the present invention is not limited or limited by the embodiments. In this description, the same symbols refer to substantially the same elements. Under this rule, the content described in other drawings can be cited for description, and the content that is judged to be self-evident or redundant by practitioners can be omitted.

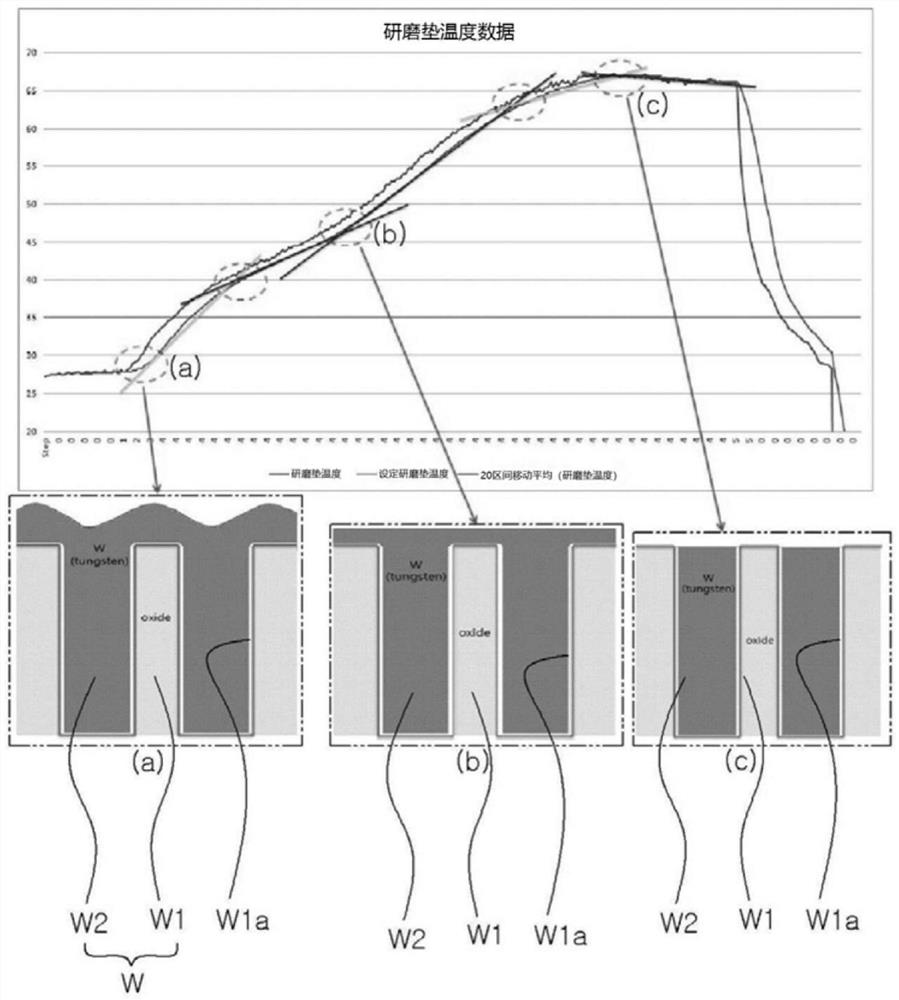

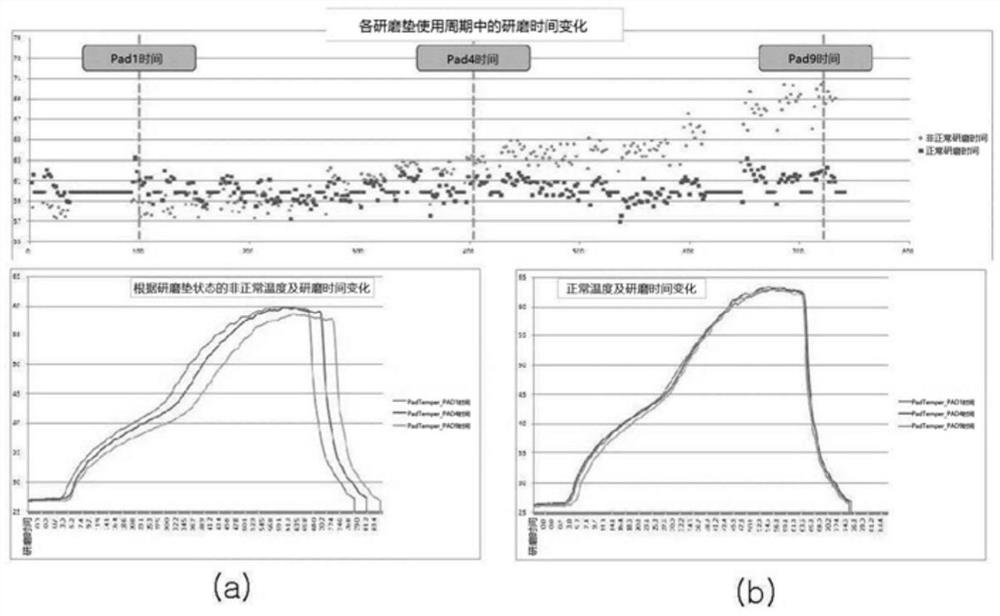

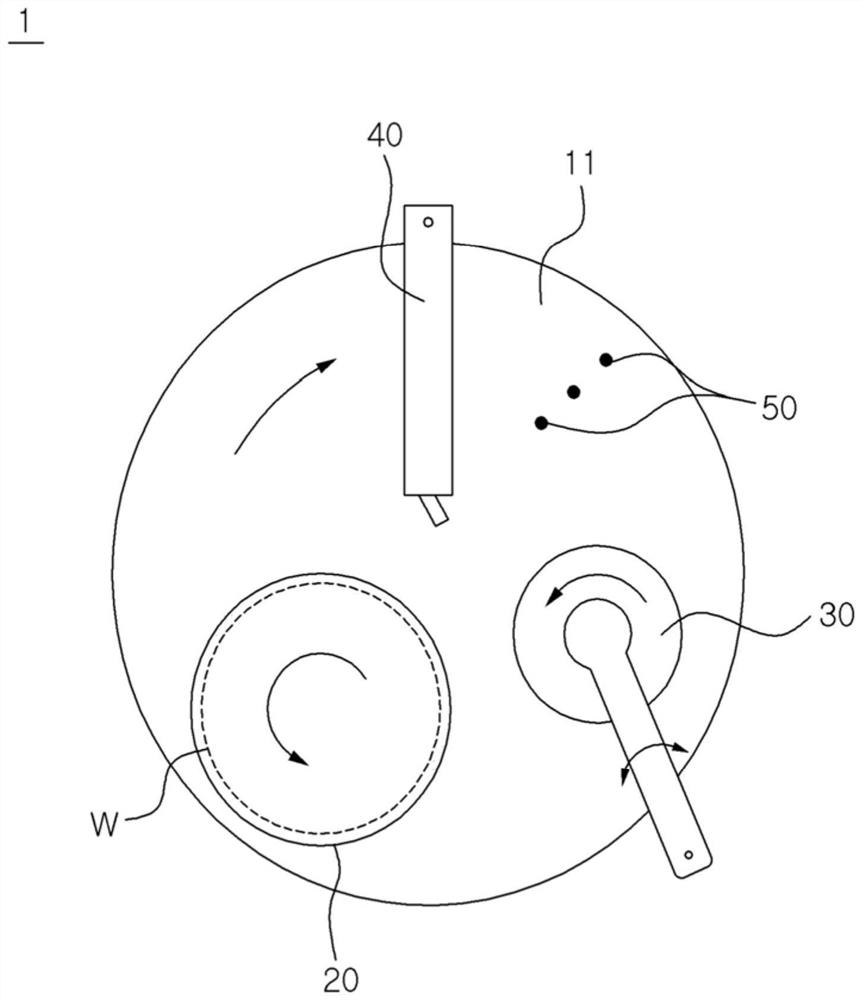

[0058] refer to Figures 3 to 13, the substrate processing apparatus 10 of the present invention includes: a polishing pad 111, which grinds the polishing layer of the substrate W; a temperature measurement unit 150, which measures the temperature information of the polishing pad 111; a control unit 160, which controls the temperature based on the temperature information of the polishing pad 111 The polishing end time point of the substrate W.

[0059] This is to accurately control the polishing thickness of the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com