IC (Integrated Circuit) card remaking device

A technology for refurbishing devices and recycling devices, applied in grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of no treatment method, affecting the appearance, environmental pollution, etc., to prevent damage to IC cards, saving resources, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

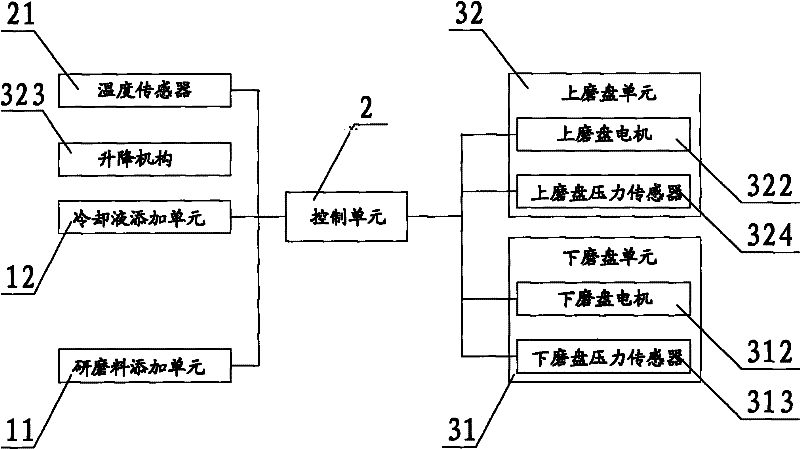

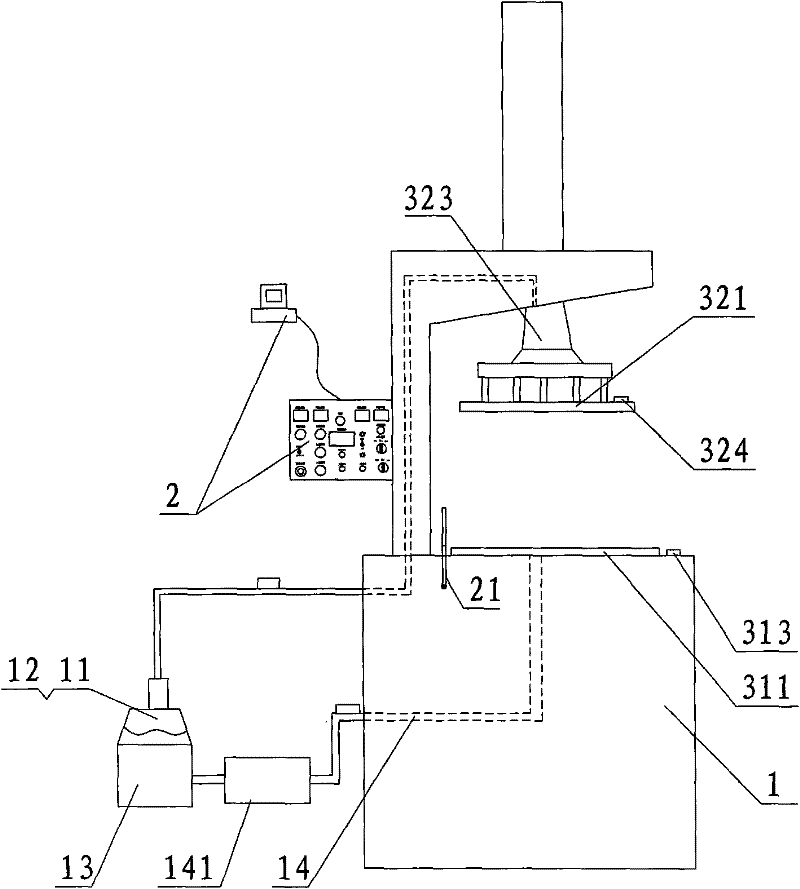

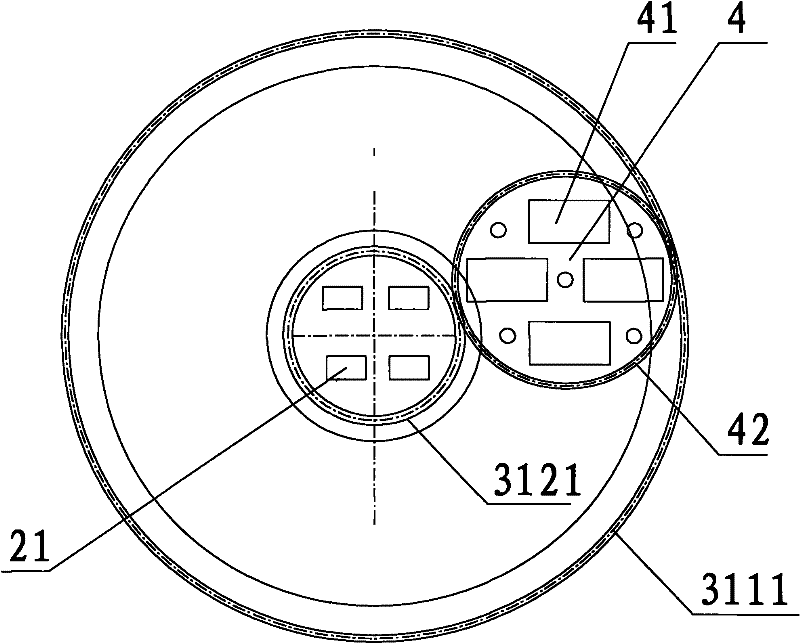

[0027] Such as figure 1 with figure 2 As shown, the IC card refurbishment device of the embodiment of the present invention comprises workbench 1, control unit 2 and the grinding mechanism 3 that is located on the workbench 1, and grinding mechanism 3 comprises lower grinding disc unit 31 and upper grinding disc unit 32, lower grinding disc unit 31 Comprising a lower grinding disc 311 and a lower grinding disc motor 312 for driving the lower grinding disc 311 , the upper grinding disc unit 32 includes a lifting mechanism 323 , an upper grinding disc 321 and an upper grinding disc motor 322 for driving the upper grinding disc 321 , and the upper grinding disc 321 is fixed on the workbench 1 through the lifting mechanism 321 The upper and lower grinding disc motors 312 , the upper grinding disc motor 322 and the lifting mechanism 321 are all connected to the control unit 2 .

[0028] In this embodiment, the lower millstone unit 31 includes a lower millstone pressure sensor 313...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com