Forming mold and forming method of negative drawing mold part

A molding method and technology of molding molds, which are applied in the field of molding molds for negative draft parts, can solve problems such as failure to meet design requirements, poor apparent quality of parts, and high porosity of parts, so as to reduce porosity and air bubbles and improve production Effect of low cost and improvement of internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

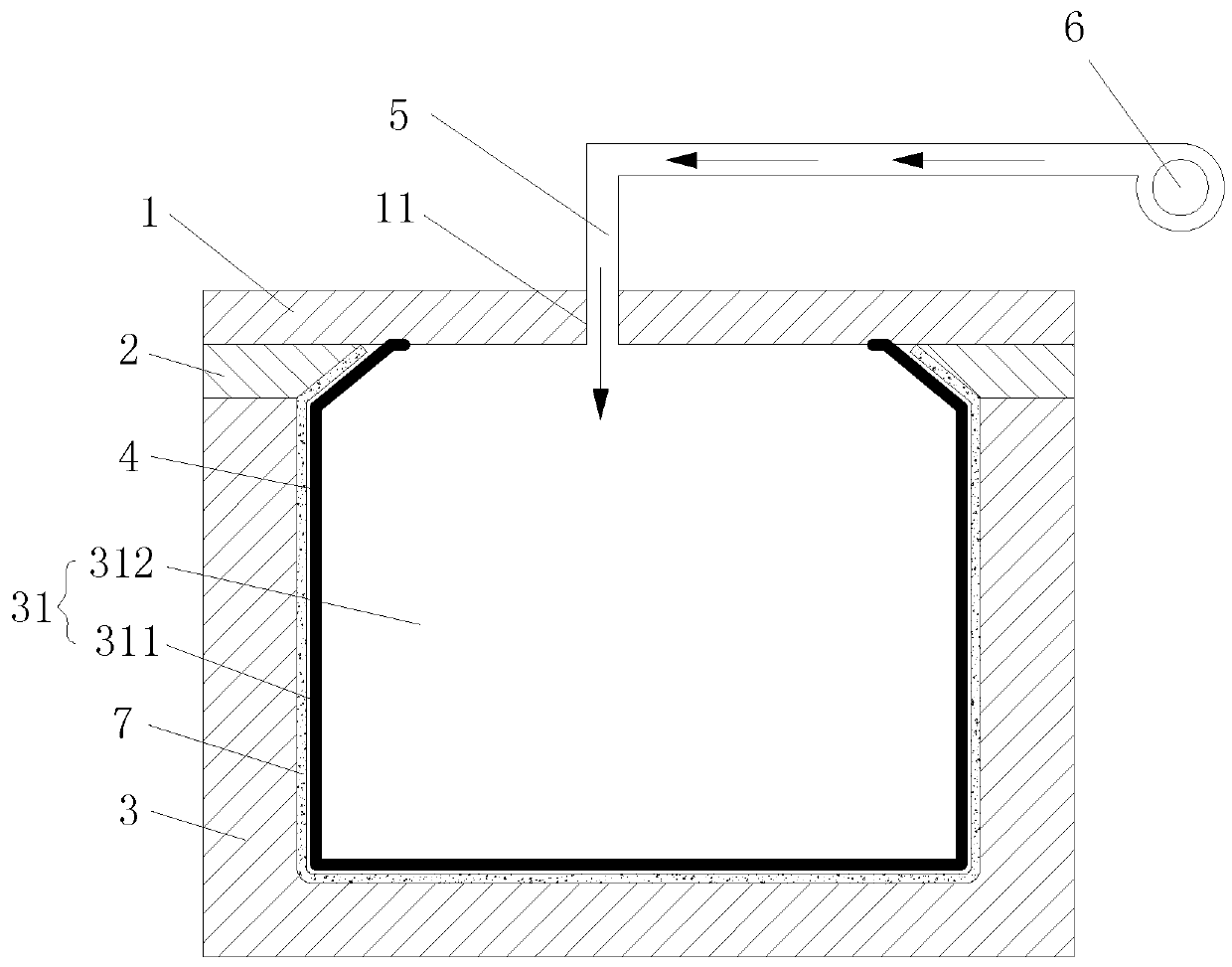

[0025] see figure 1 , this embodiment discloses a forming mold for negative draft parts, which at least includes a first mold 1 and a second mold 3. When the first mold 1 and the second mold 3 are closed, a cavity 31 is enclosed, and the cavity 31 can be It is directly arranged in the second mold 3, the cavity 31 is connected with a sealing film 4, and the edge of the sealing film 4 is sealed with the inner wall of the cavity 31;

[0026] The sealing film divides the cavity into a first cavity 311 and a second cavity 312, a first cavity 311 is formed between the sealing film 4 and the inner wall of the cavity 31, and the second cavity 312 communicates with the air compressor 6 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com