Mechanical power transmission device of crankshaft, flywheel lever and connecting rod structure

A technology of mechanical power and transmission devices, which is applied in the field of mechanical power transmission devices and mechanical power transmission devices, can solve the problems of insufficient mechanical power and speed, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

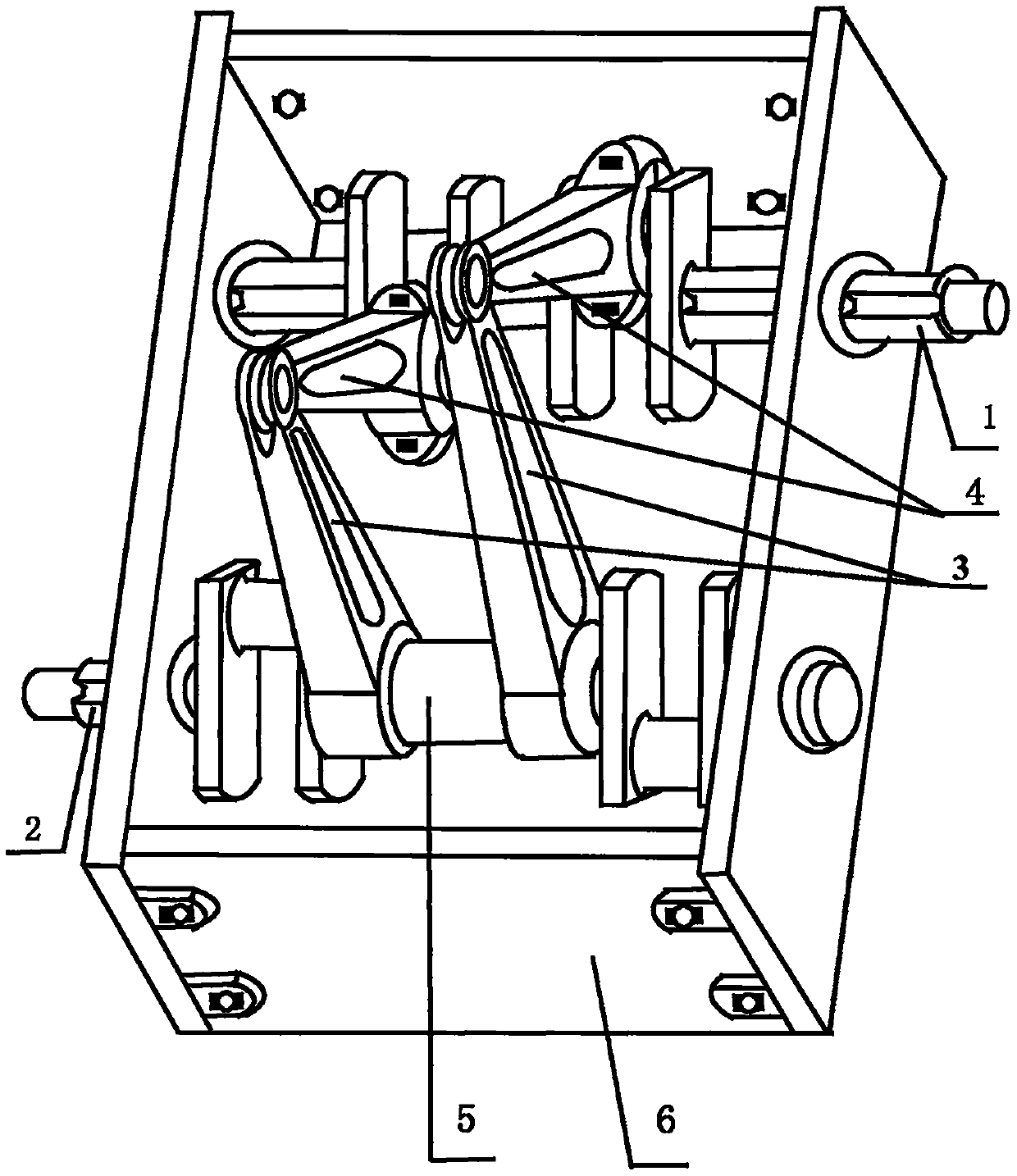

[0047] Such as figure 1 ,Such as Figure 3-10 Shown, a kind of mechanical power transmission device of crankshaft flywheel lever connecting rod structure, comprises crankshaft 1 (1), crankshaft 2 (2), flywheel lever (3), connecting rod (4), crankcase (6);

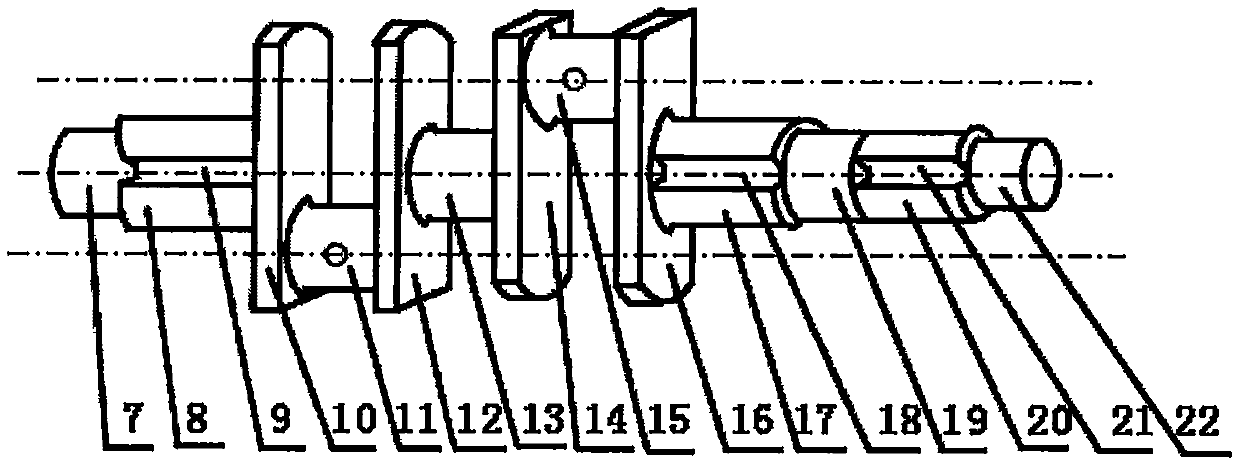

[0048]One end of the crankshaft 1 (1) is provided with the front end shaft 1 (7), one end of the front end shaft 1 (7) is provided with the main journal 1 (8), and the front end shaft 1 (7) is connected to the The main journal 1 (8) is cast into one body, the main journal 1 (8) is provided with the square groove 1 (9), the other end of the main journal 1 (8) and the crank arm 1 (10) The center position is shrink-fit connection, the other end of the crank arm 1 (10) is provided with the connecting rod journal 1 (11), and the other end of the connecting rod journal 1 (11) is provided with the crank arm 2 ( 12), the crankshaft arm 1 (10) and the connecting rod journal 1 (11) are integrally cast, and the connecting rod journa...

Embodiment 2

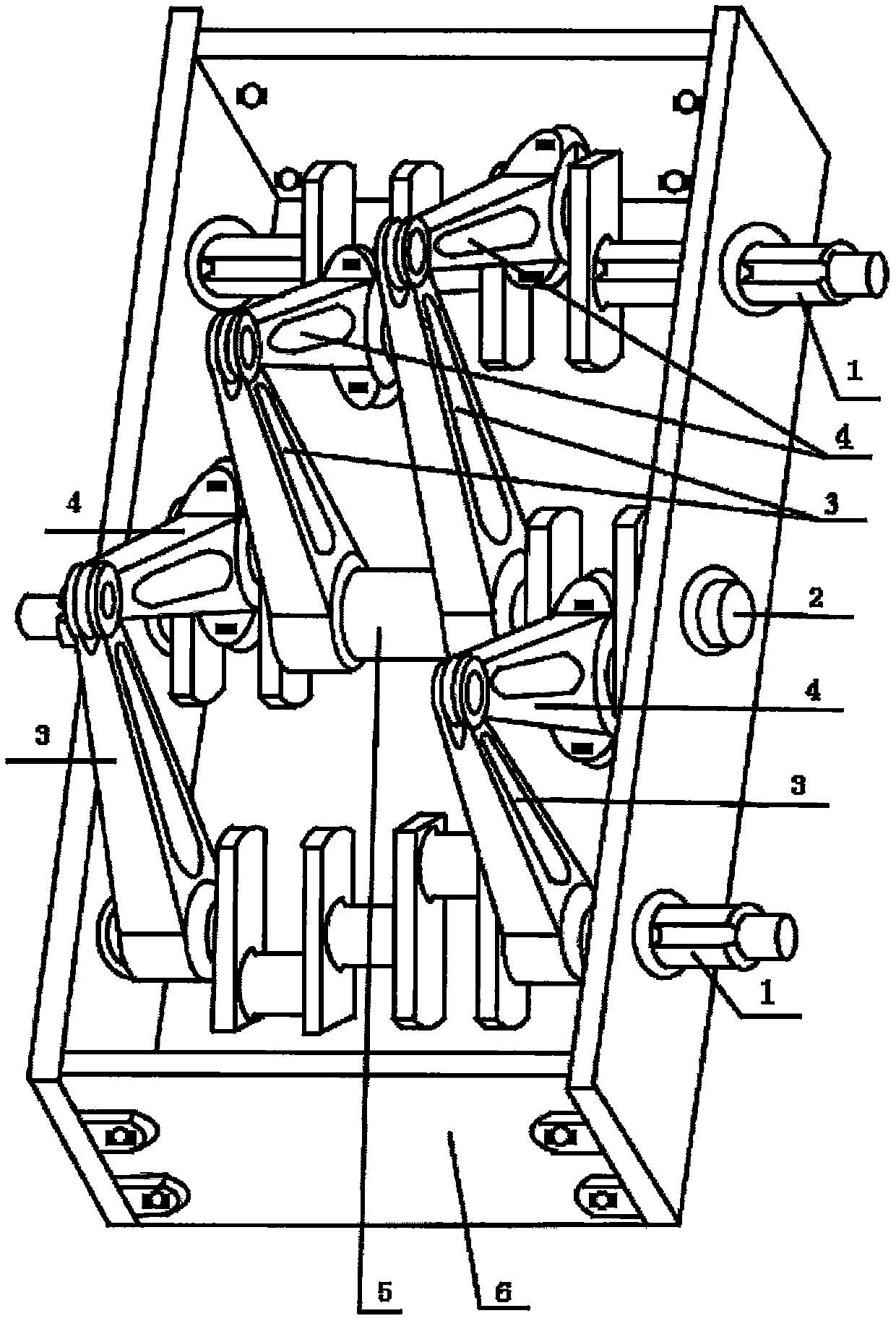

[0062] Such as figure 2 --shown in 10, the difference between this embodiment and embodiment 1 is: on the basis of embodiment 1, a described crankshaft 1 (1), described flywheel lever (3), described connecting rod (4) are added ) combination structure, has formed described crankshaft 1 (1), described crankshaft 2 (2), described flywheel lever (3), described connecting rod (4) two groups of crankshaft combination structures.

[0063] The front end shaft 1 (7) is connected to the upper bearing, the rear end shaft 1 (19) is connected to the upper bearing and is rotatably connected to the bearing hole (59), and the lever big head flywheel (42) is connected to the main journal 1 ( 8) Square groove card connection, the lever big head flywheel (42) is connected with the square groove card of the main journal 3 (17), the connecting rod big head (52) is connected to the upper connecting rod bearing bush, the connecting rod bearing cover (47) Connect the lower connecting rod bearing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com