A liquid natural gas regasification system for fsru

A technology of liquefied natural gas and natural gas, applied in the field of FSRU, can solve the problems of slow gasification speed of natural gas, freezing of seawater cooling, condensation of marine organisms, etc., and achieve the effect of fast gasification speed and stable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

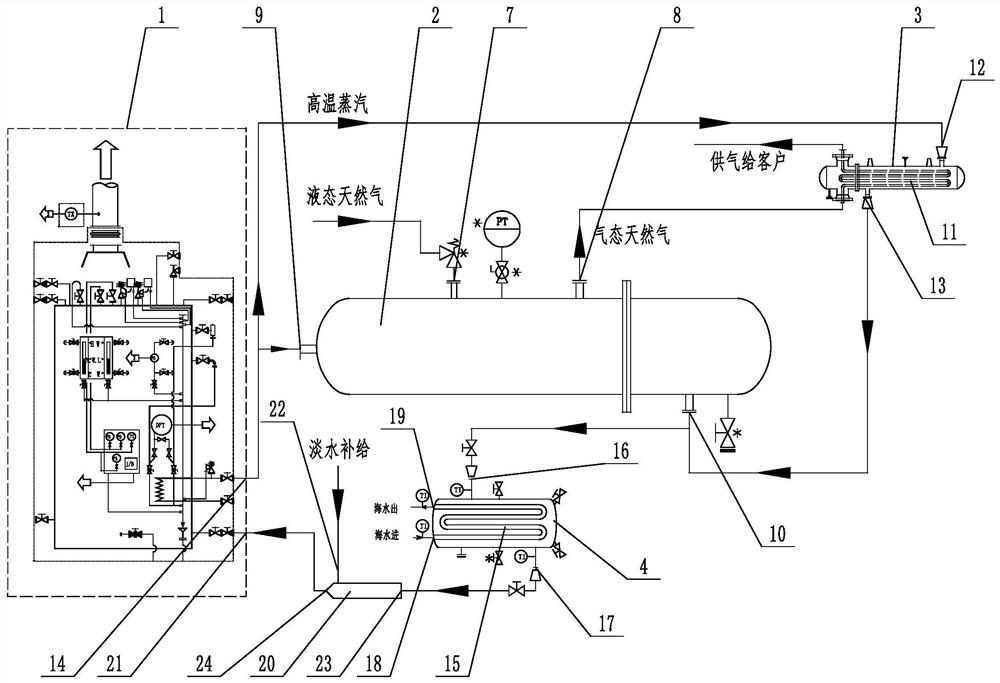

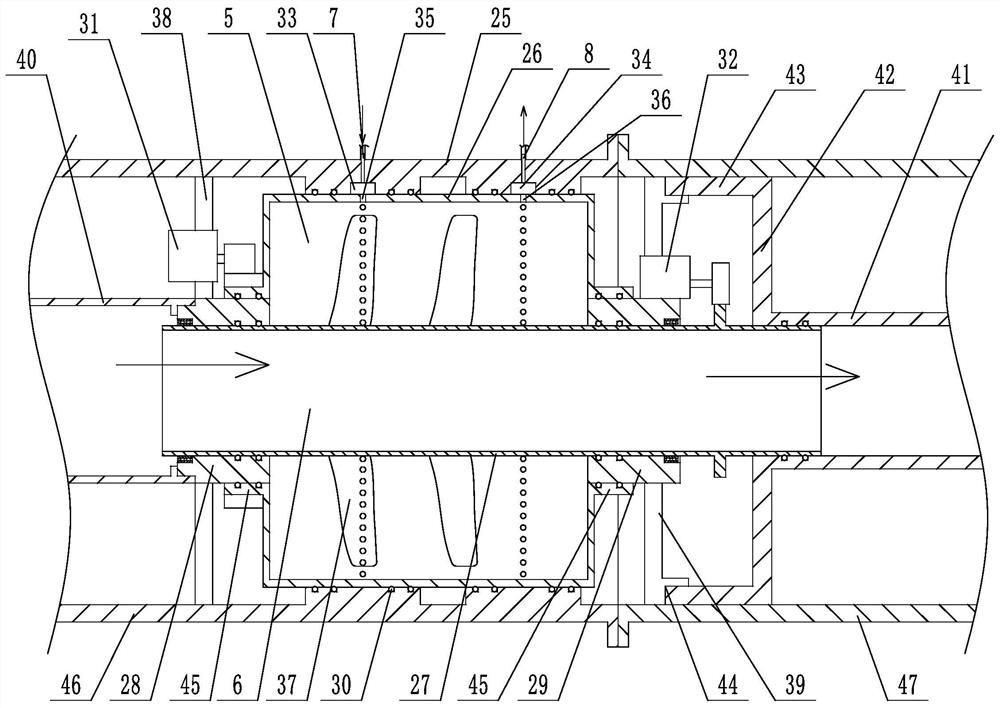

[0021] Embodiment: A kind of liquefied natural gas regasification system for FSRU (see attached figure 1 , attached figure 2 ), including a boiler 1, a primary gasification device 2, a secondary heating device 3, and a condenser 4. The primary gasification device is equipped with a gasification chamber 5 and a heating chamber 6. The heating chamber heats the gasification chamber. The first-stage gasification device is provided with a liquid natural gas inlet 7 and a gaseous natural gas outlet 8 connected with the gasification chamber, and the first-stage gasification device is provided with a first-stage steam inlet 9 and a first-stage steam outlet 10 connected with the heating chamber; A heat exchange tube 11 is installed in the device, a secondary steam inlet 12 and a secondary steam outlet 13 are arranged on the secondary heating device, a steam supply port 14 is provided on the boiler, and the primary steam inlet and the secondary steam inlet are connected with the steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com