A kind of expressway guardrail height rapid detection equipment and detection method

A technology for highways and testing equipment, applied in the direction of measuring devices, instruments, etc., can solve the problems that the staffing cannot meet the needs, are prone to false detection and missed detection, and increase the detection cost, so as to shorten the detection time, improve the use time, The effect of short detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

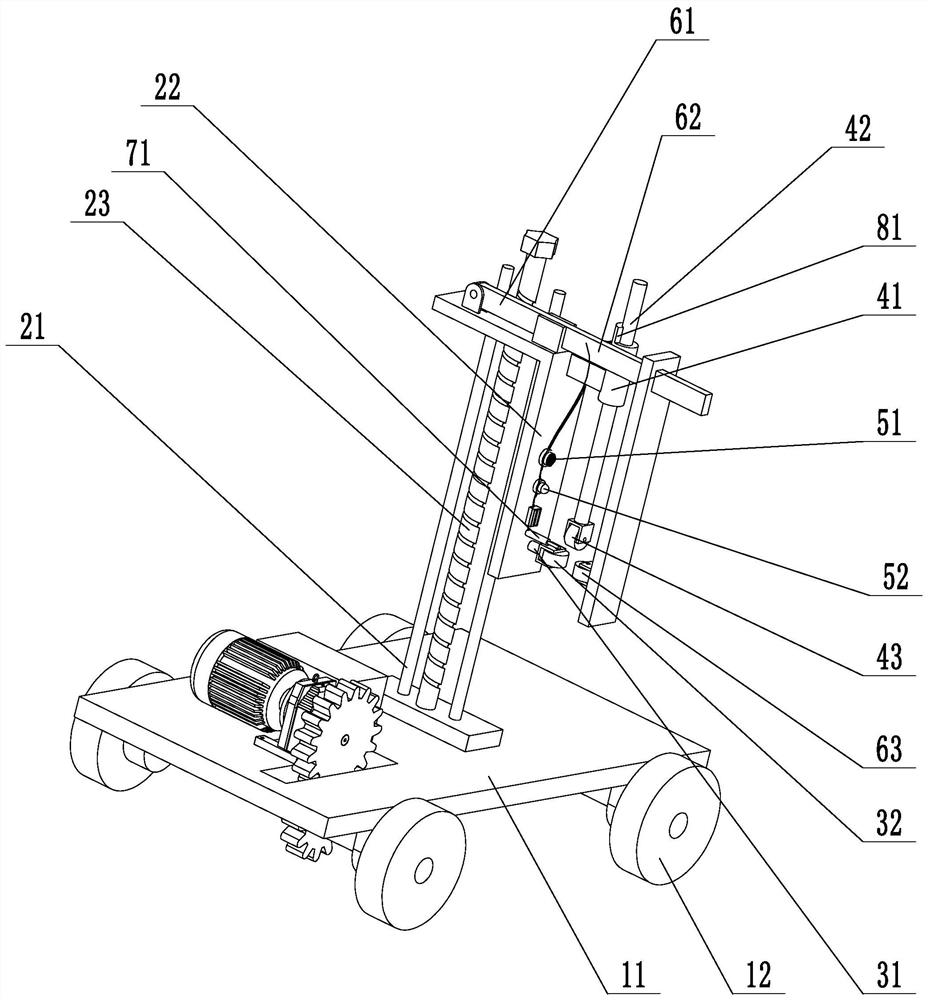

[0045] refer to figure 1 , is a highway guardrail height rapid detection device and detection method thereof disclosed in the present invention, including several parts such as a mobile base, a height adjustment part, a dynamic testing part, a guiding part and an auxiliary guiding part.

[0046]The mobile base includes a chassis 11, four road wheels 12 arranged on the chassis 11 and a driving device installed on the chassis 11. The drive device consists of a motor and a reducer, and a drive gear is installed on the output shaft of the reducer. Four traveling wheels 12 are divided into two groups, and one group is front-wheel, and one group is trailing wheel, and front-wheel is universal wheel, is responsible for adjusting walking direction, and trailing wheel is directional wheel, is responsible for providing power. A transmission shaft is arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com