An RFID-based unmanned aerial vehicle intelligent hangar material checking and optimizing method

A technology of intelligent hangar and optimization method, applied in the field of drones, can solve the problems of no template and technical implementation plan, misidentification, missing identification of drone material inventory, etc., so as to shorten the time of entering and leaving the warehouse and increase the efficiency of the warehouse , Improve the effect of recognition satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An RFID-based inventory and optimization method for UAV smart hangar materials, including a UAV smart hangar material inventory method and a UAV smart hangar material inventory optimization method, the UAV smart hangar material inventory method includes entering Inventory management, outbound management, outbound optimal solution, and in-stock management, the UAV smart hangar material inventory optimization method includes the optimization of interference labels and false positives, and the optimization of missed negatives.

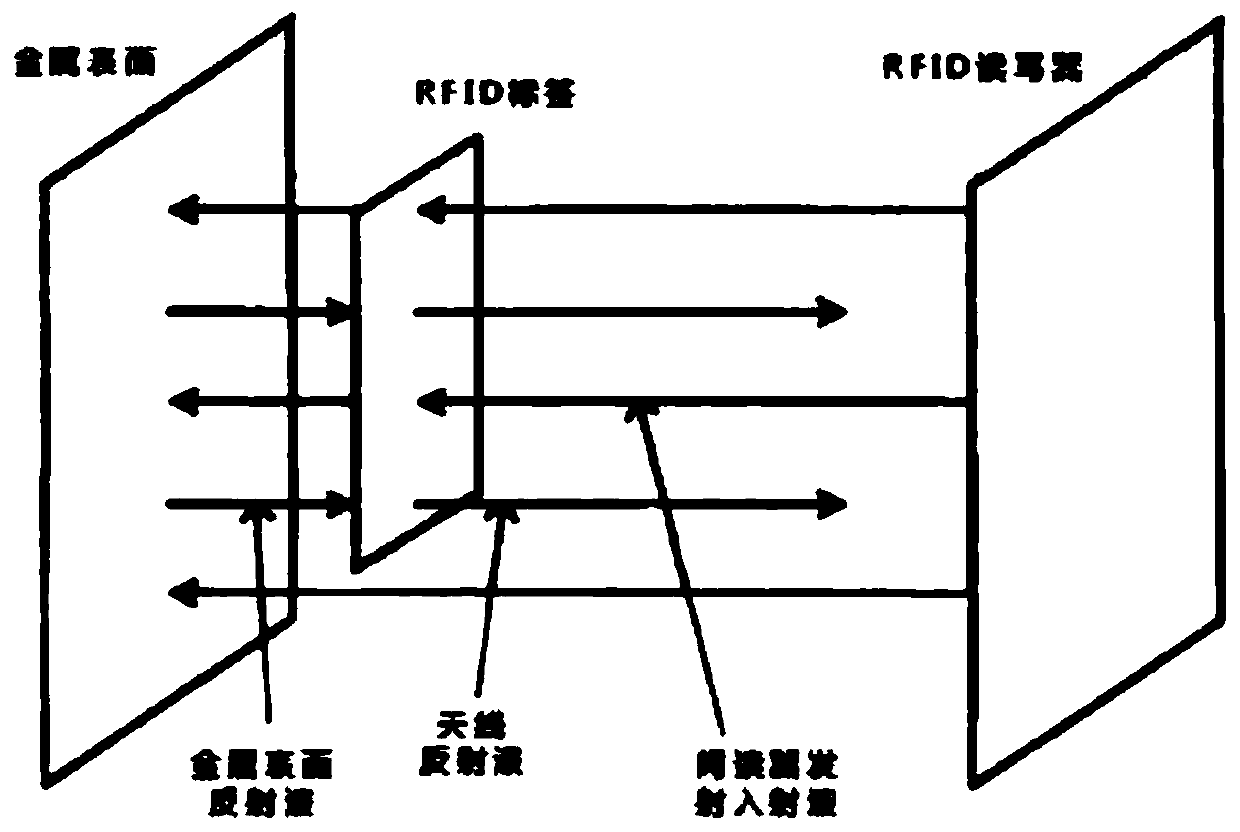

[0037] It is worth noting that, if figure 1 As shown, due to the particularity of UAV material tags, the present invention uses anti-metal RFID tags. Although ordinary passive RFID tags are cheap, they are prone to missing recognition in practical applications due to their short working distance. At the same time, more importantly, metal objects will have a great impact on tag recognition performance. There are two main aspects, one is the antenna ...

Embodiment 2

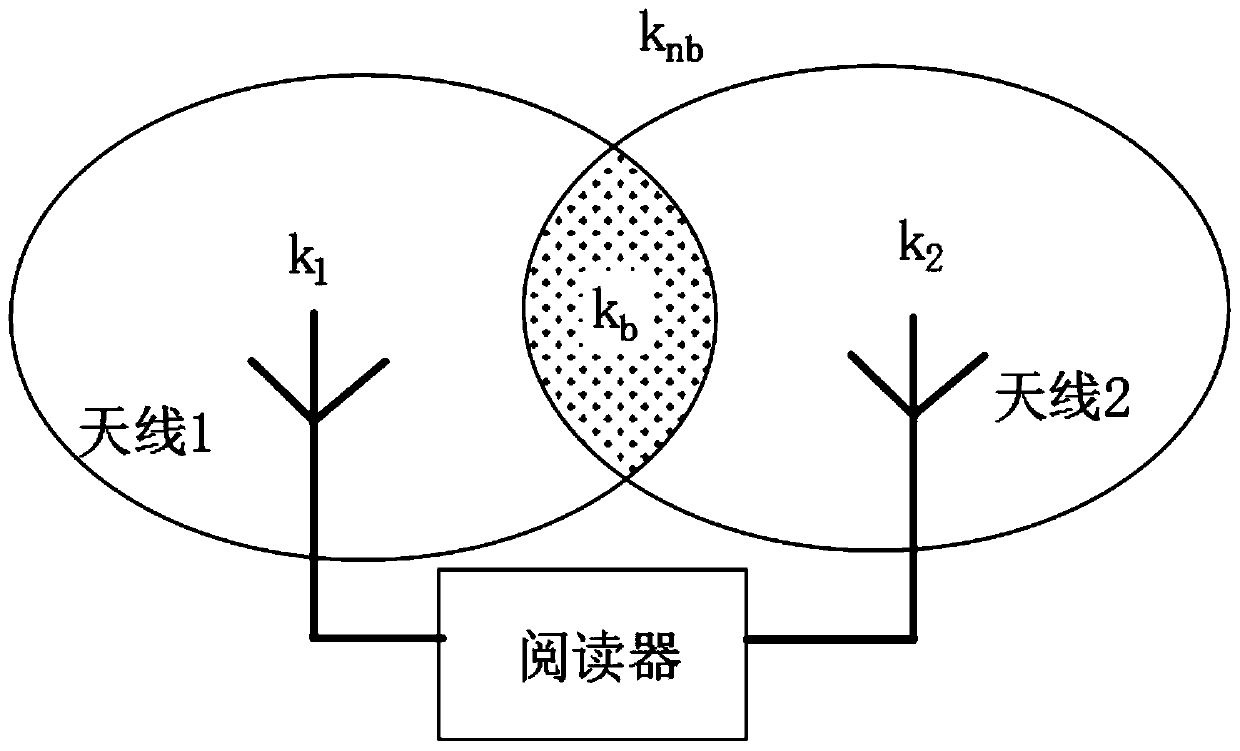

[0066] As the second embodiment of the present invention, the tag reader is provided with two antennas to identify the electronic tags separately, and the identification is performed separately, and there is no frequency interference problem caused by multiple antennas of the reader, such as figure 2 As shown, the number of tags that antenna 1 can recognize is k 1 , the number of tags that antenna 2 can recognize is k 2 , the number of tags that both antennas can recognize is k b , the number of tags not recognized by the two antennas is k nb ,make:

[0067] k=k 1 +k 2

[0068] In the formula, k represents the number of tags that the reader can fully identify under the two antenna identification modes. Then when the i antennas are activated:

[0069] k=k 1 +k 2 +k 3 +Λ+k i

[0070] In a system where a multi-antenna RFID reader identifies multiple electronic tags, the antenna and the tag are used as two different carriers. Given m tags and n antennas, the tag vect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com