Industrial flexible cable

A flexible cable and industrial technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve problems affecting the safety and reliability of industrial robots, industrial robot failures, cable damage, etc. Stretch and torsion resistance enhancement, enhance the effect of tensile and torsional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] When the industrial robot is moving, relative motion occurs between the joint manipulators, which puts forward high requirements on the tensile and torsion resistance of the cables connected between the joint manipulators. In actual production, the damage of the above-mentioned cables mainly comes from the fact that most of the force received during its own torsion or stretching process is converted into the stress of the cable rather than the movement displacement.

[0032] The present invention will be further described in detail below with reference to the examples and figures, but the embodiments of the present invention are not limited thereto.

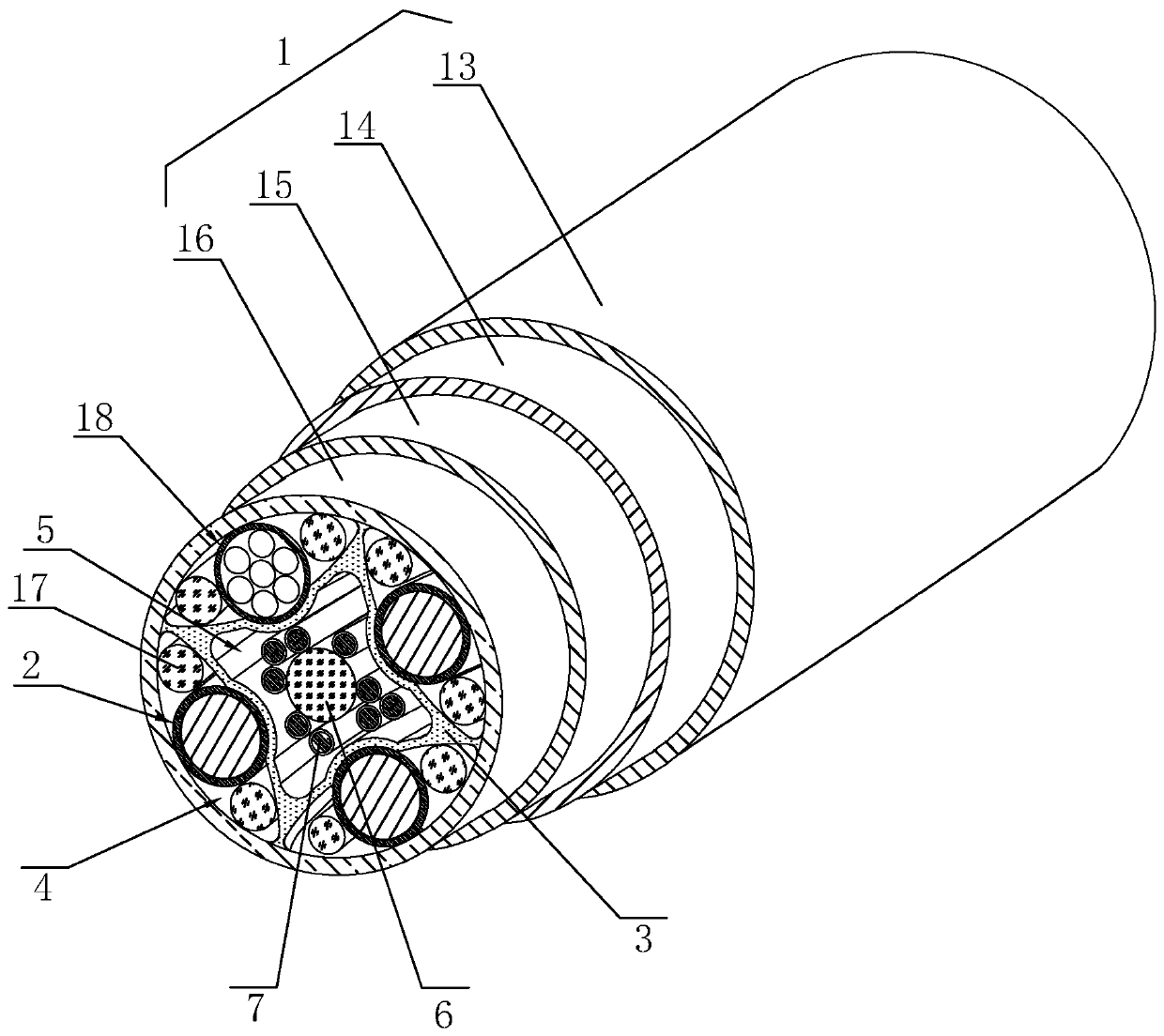

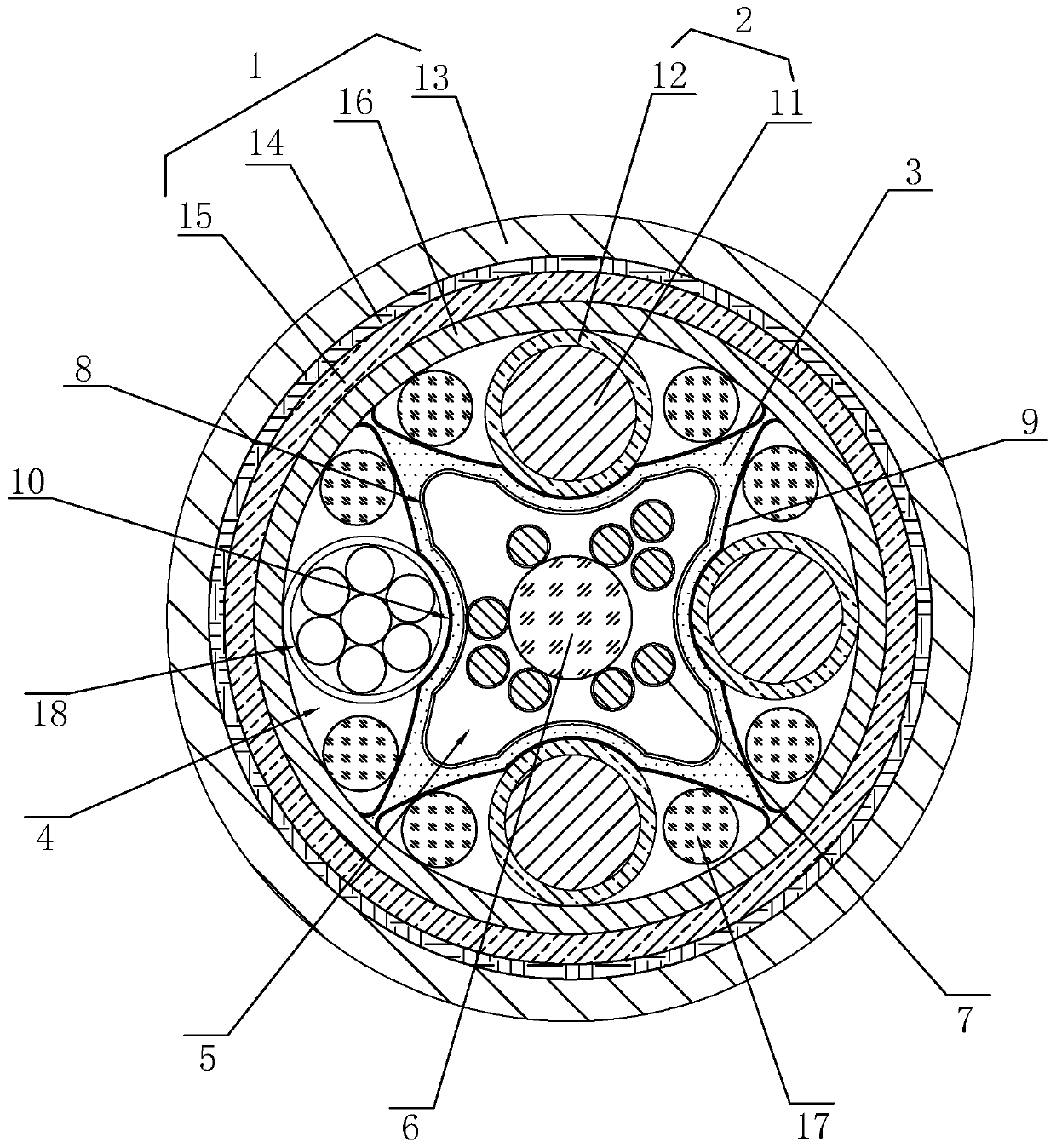

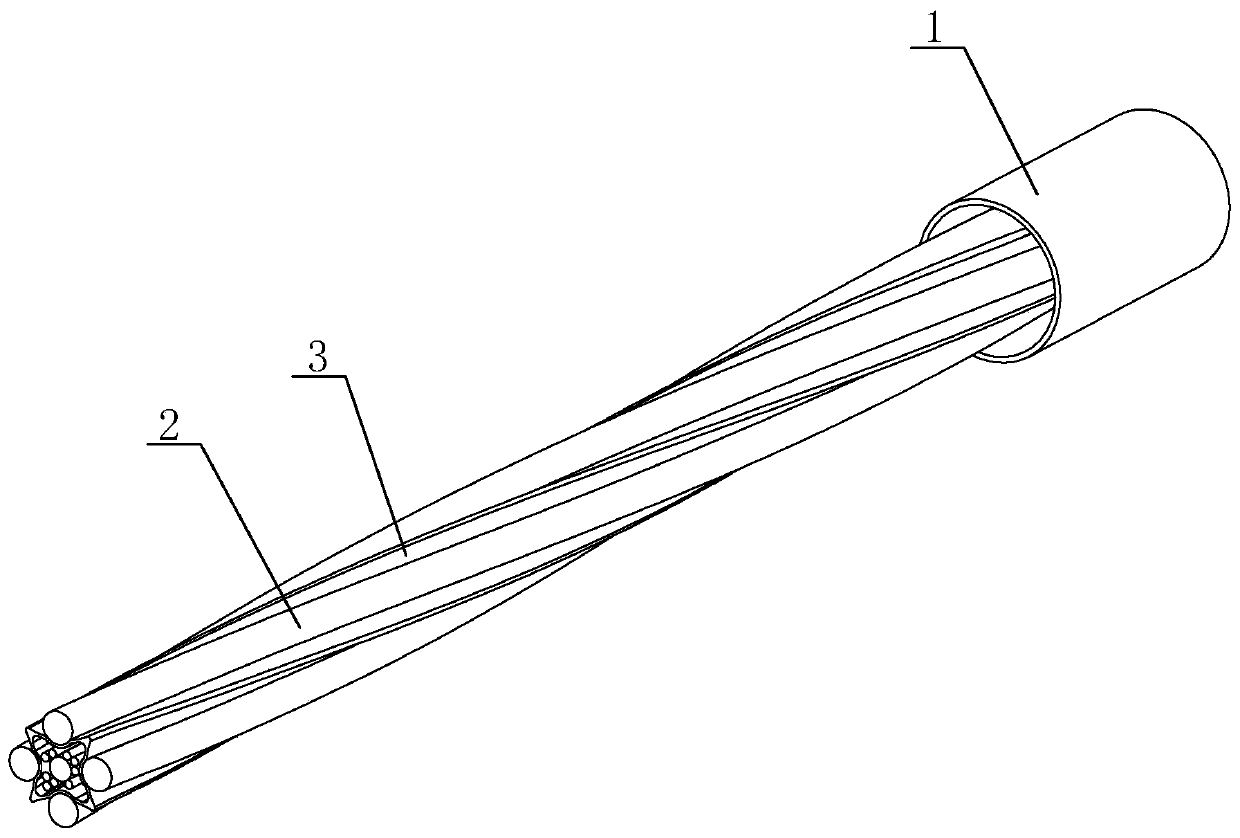

[0033] Such as figure 1 with figure 2 As shown, an industrial flexible cable includes a sheath layer 1 and a plurality of wire cores 2 arranged in the sheath layer 1 . In the sheath layer 1, along the length direction of the cable and coaxial with the cable, an elastic filling strip 3 is arranged. Core 2 placement chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com