Rotor for a motor

A motor rotor and shaft technology, which is applied in the field of motor rotors, can solve the problems of vibration, shortening the service life of the motor, and unsmooth operation, so as to achieve the effects of reducing vibration, smooth operation, and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 5 example

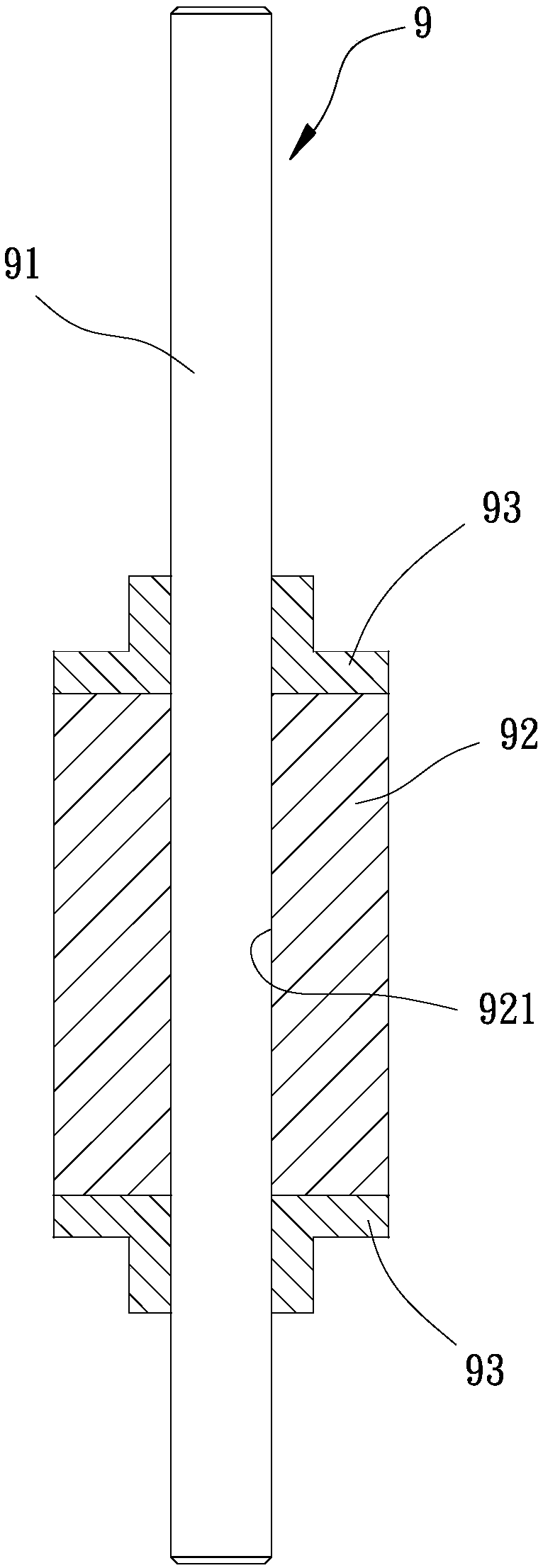

[0074] Please refer to Figure 8 , which is the fifth embodiment of the motor rotor of the present invention. The fifth embodiment of the present invention is substantially the same as the above-mentioned first embodiment. At least one first engaging portion 32 is provided, and at least one second engaging portion 45 is respectively provided on one of the axial end faces of the two assembly parts 4e, so that the two assembly parts 4e can be separated by the at least one The second engaging portion 45 is engaged with the corresponding first engaging portion 32, so as to improve the joint stability between the two assembly parts 4e and the permanent magnet 3, and at the same time help to quickly connect each assembly part 4e The plurality of positioning holes 42 on the upper part are opposite to the plurality of through holes 22 of the elastic collar 2, so as to lock the fixing component 5, so as to improve the convenience and efficiency of assembly.

[0075] Wherein, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com