Revolution and rotation combined smashing knife roll corn stalk returning machine

A corn stalk and combined technology, applied in the field of agricultural machinery, can solve the problems of reducing the effect of corn stalk returning to the field, and the crushing quality of corn stalks cannot adapt to and meet the requirements of corn stalk returning to the field, so as to improve the crushing quality and operation effect , novel structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

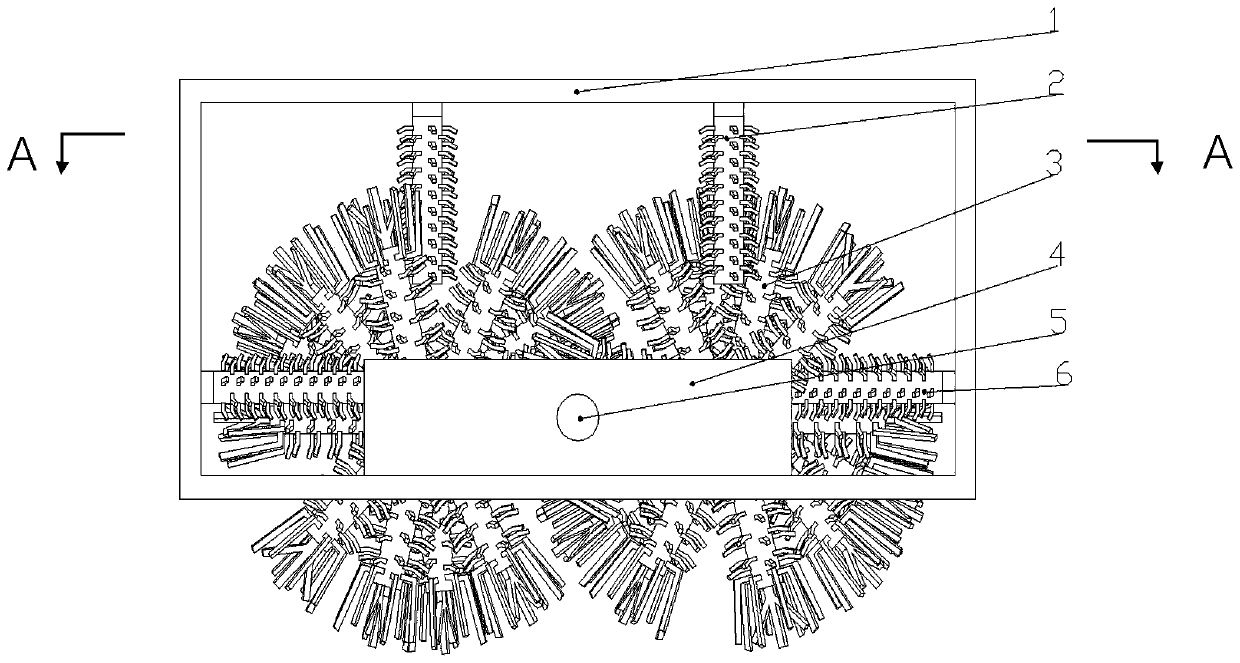

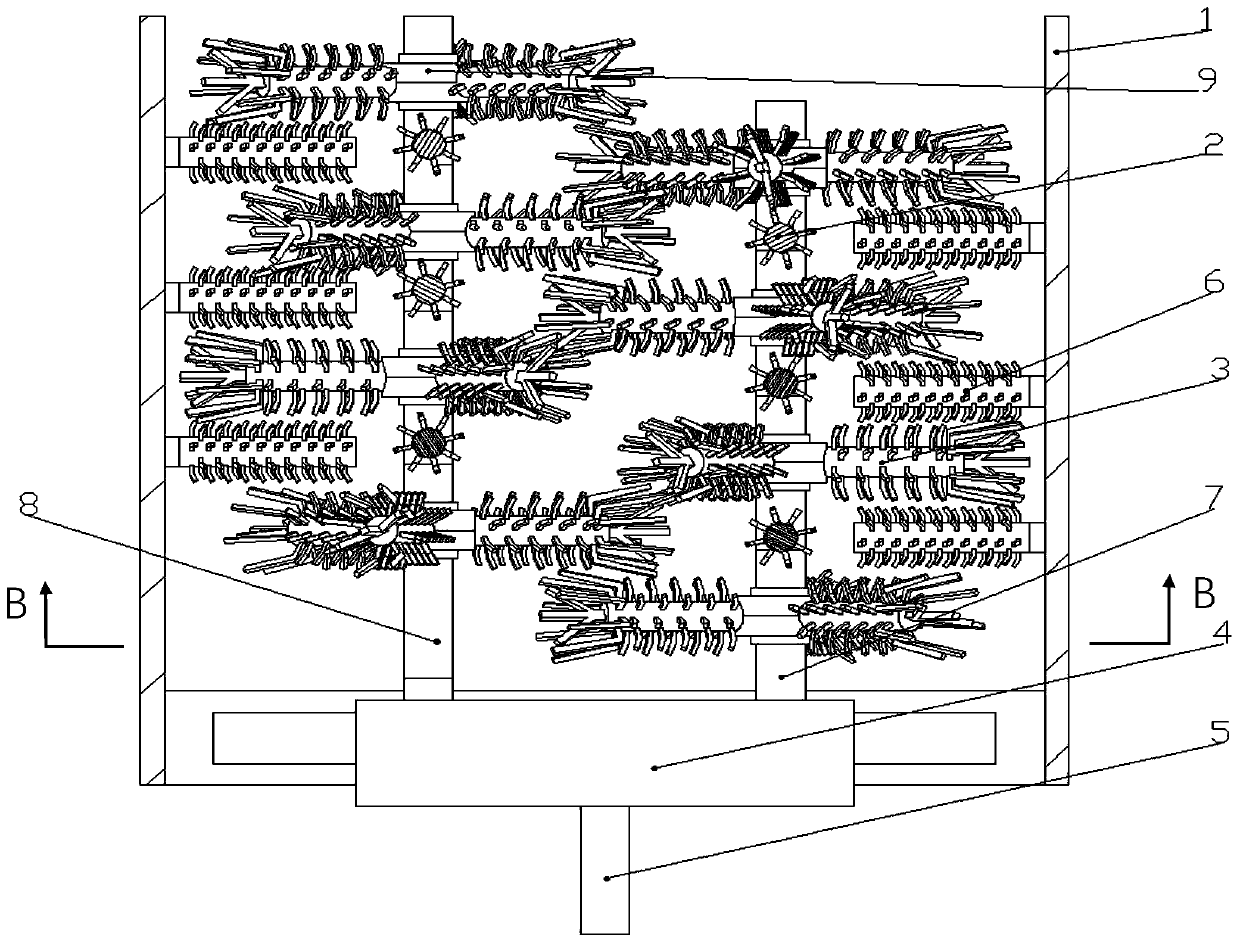

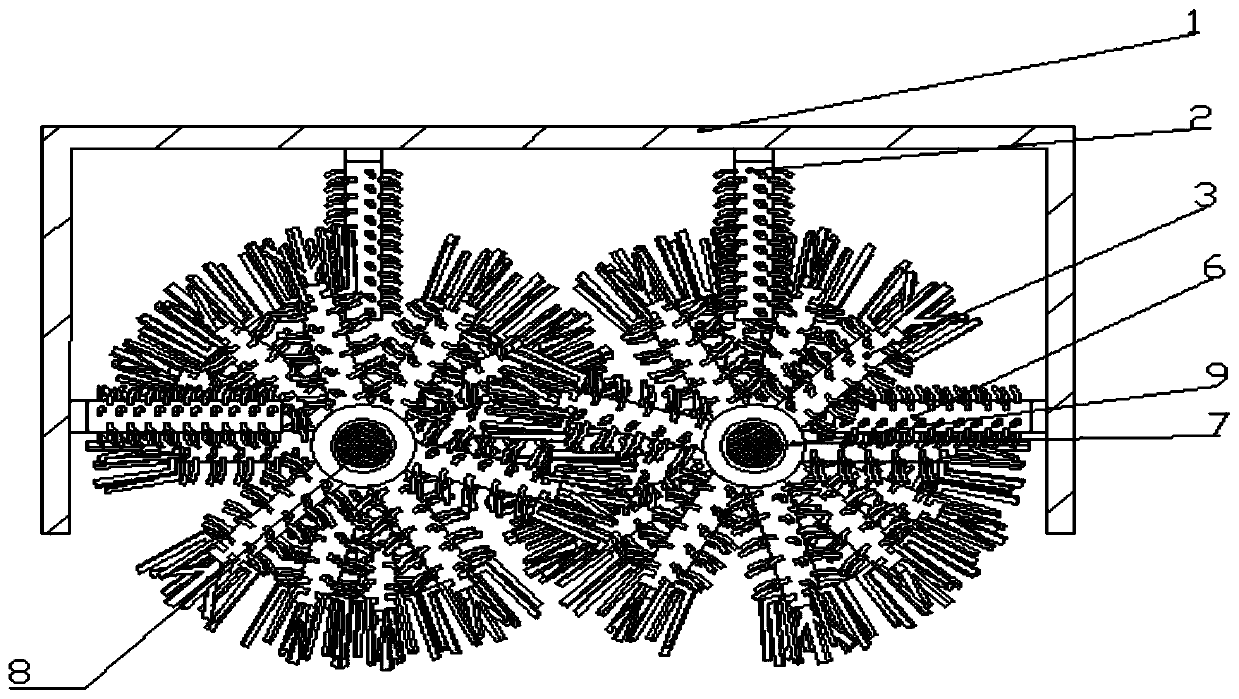

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A combined revolution and rotation crushing knife roller corn stalk returning machine, a gear transmission box 4 with a power input shaft 5 is installed on the front end of the frame assembly 1, and a gear transmission box 4 with a power input shaft 5 is installed on the middle part of the frame The power output right shaft 7 and the power output left shaft 8 that are parallel to each other and rotate along the longitudinal direction are connected with the gear transmission box 4 respectively, and the power output right shaft 7 The rotation direction of the power output left shaft 8 is the same as that of the power output right shaft 7 and the power output left shaft 8. N moving knife shaft mounting seats 9 are respectively fixed at equal intervals from front to back on the power output right shaft 7 and the power output left shaft 8, and the power output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com