Spray coating device for protective film

A technology of spraying device and protective film, applied in the direction of spraying device, etc., can solve the problems of low production efficiency and complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The embodiments in the following description are only examples, and those skilled in the art can think of other obvious modifications.

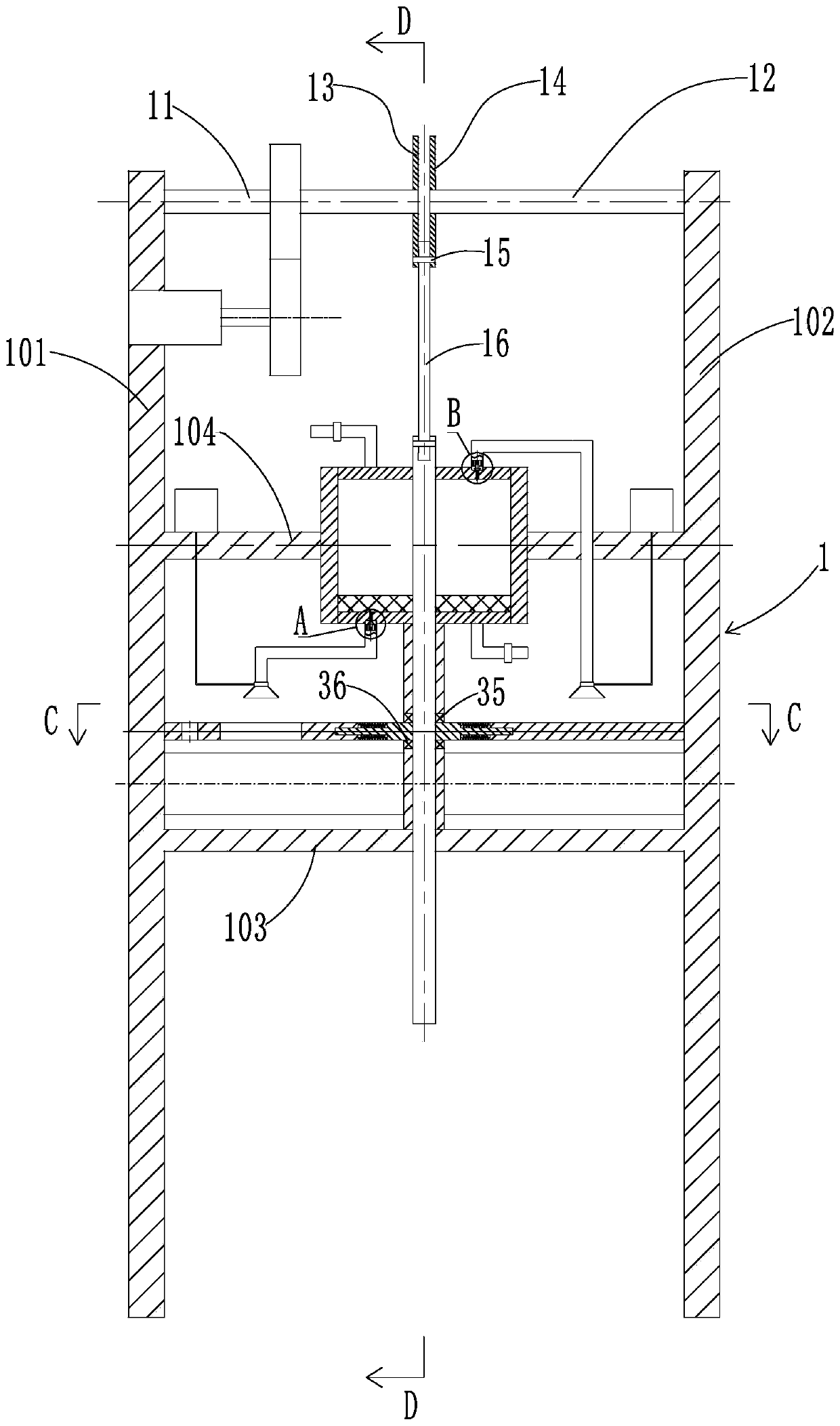

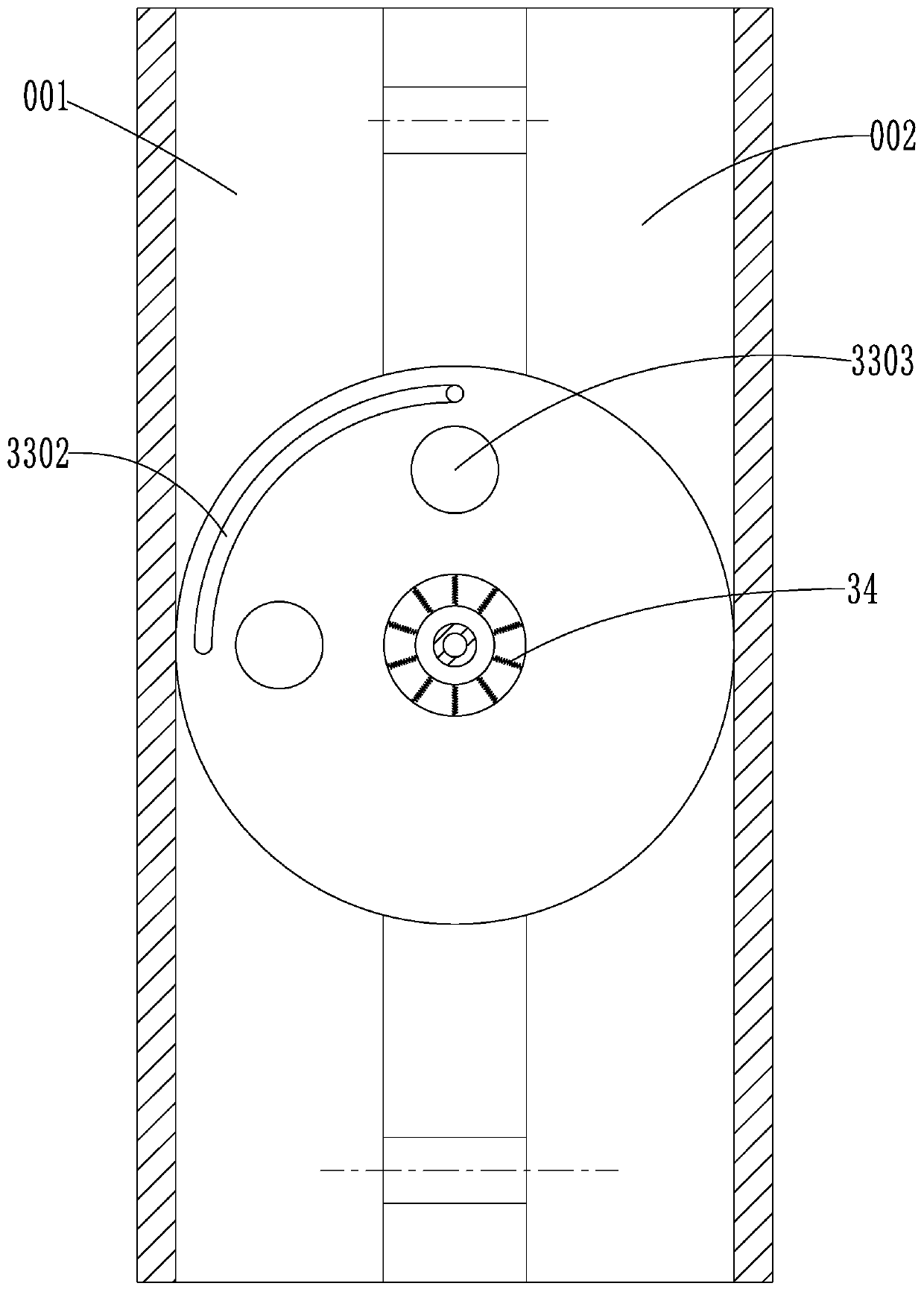

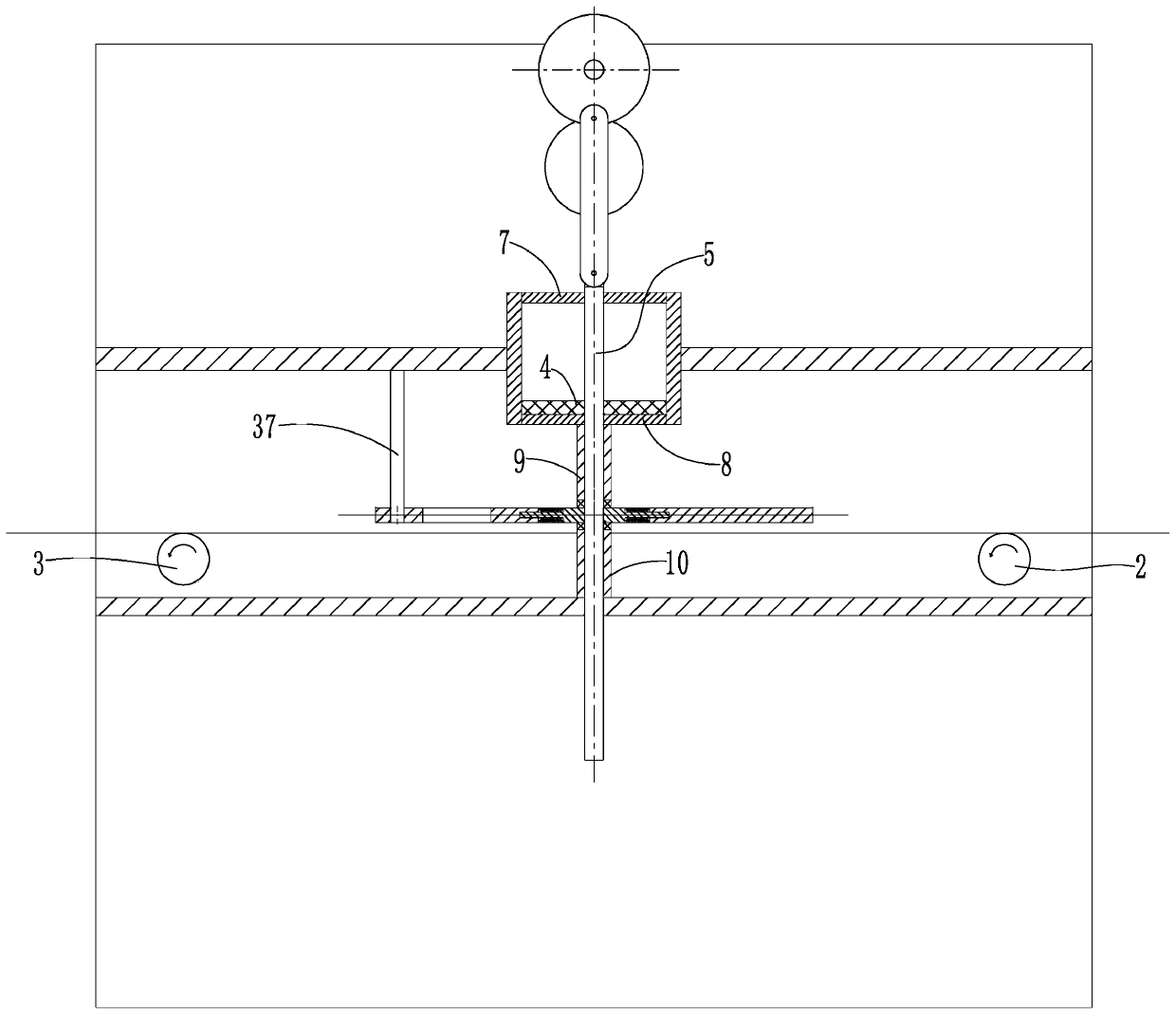

[0029] Such as Figure 1-7 As shown, a protective film spraying device includes a frame 1, and the frame 1 includes a left side plate 101 and a right side plate 102 arranged in parallel in the vertical direction, between the left side plate 101 and the right side plate 102 There is a lower horizontal plate 103 and an upper horizontal plate 104 arranged in the horizontal direction between them, and the upper horizontal plate 104 is located above the lower horizontal plate 103; There are two lead-in rollers 2 and lead-out rollers 3 of the same size and arranged parallel to each other, the axes of the lead-in rollers 2 and the lead-out rollers 3 are in the same horizontal plane and are located below th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap