Holemaking tool with independent drill point in the center

A hole processing and drilling technology, applied in the field of hole processing tools, can solve the problems of small cutting load, poor centering ability, and reduce the stability of the cutting workpiece, so as to ensure dimensional accuracy and surface quality, avoid excessive cutting temperature, The effect of excellent collapse resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

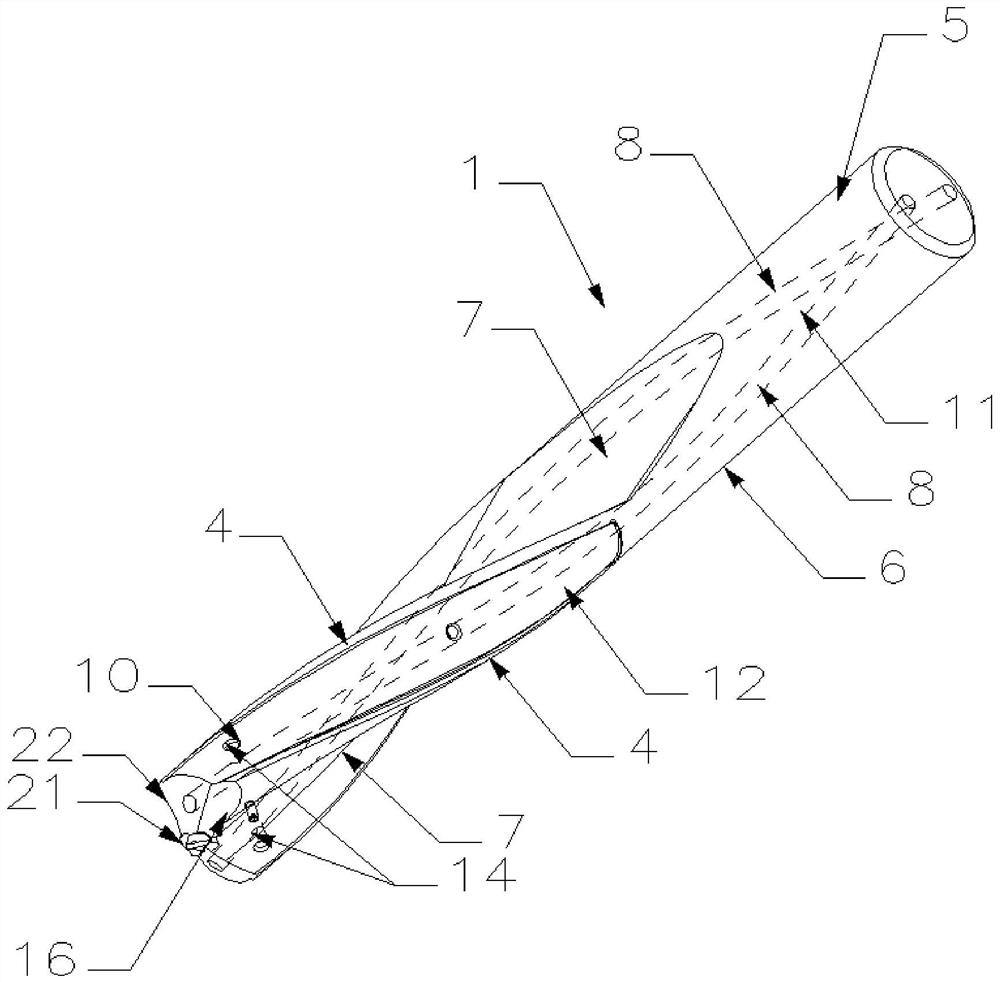

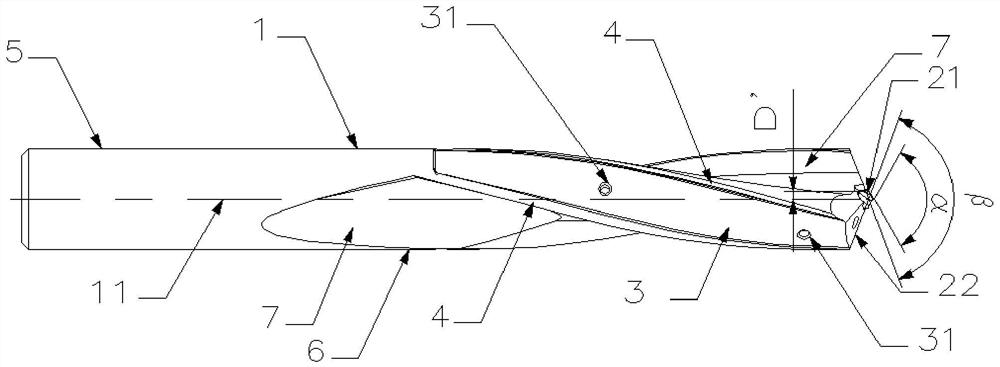

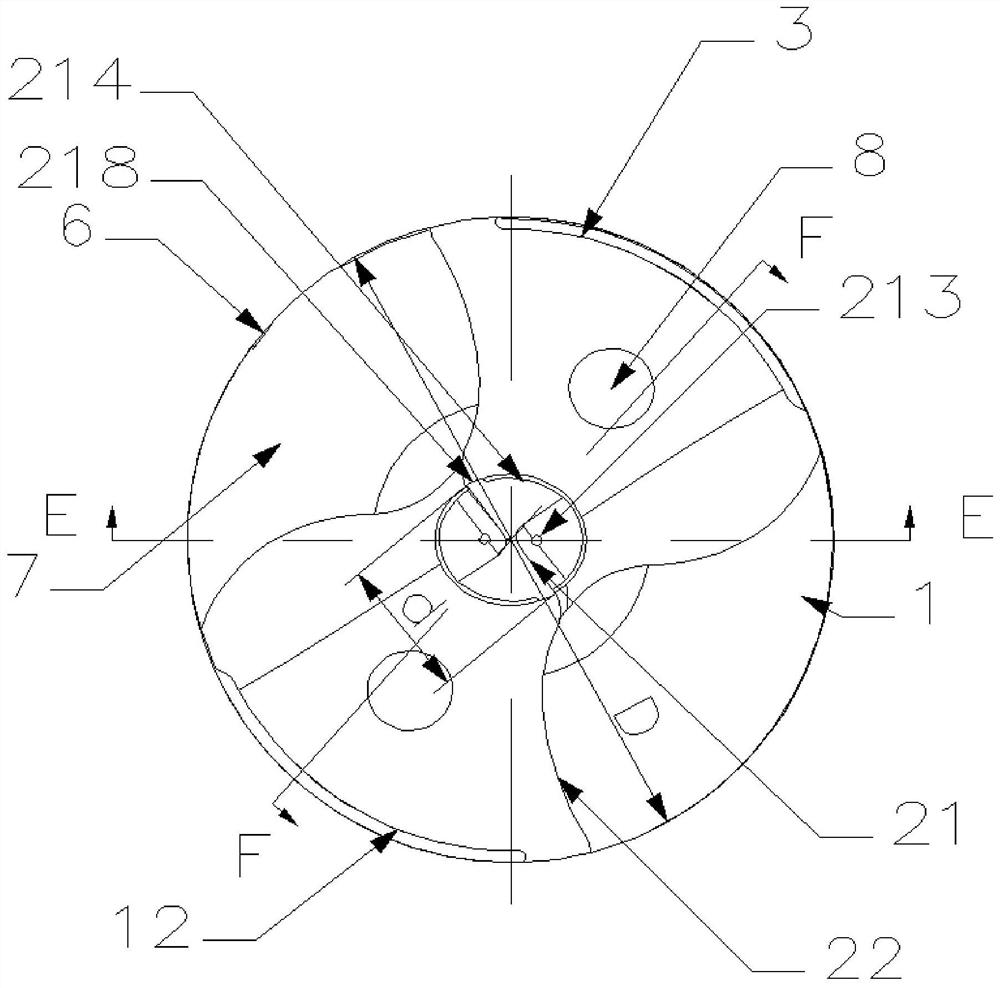

[0032] Such as Figure 1 to Figure 5 As shown, the center of this embodiment has a hole processing tool with an independent drill tip, including a cutter body 1 and a drill tip 2, and the drill tip 2 includes an inner drill tip 21 and an outer drill tip 22, and the outer drill tip 22 is arranged on the cutter body 1 , the inner drill tip 21 is installed in the center of the outer drill tip 22 and forms the core of the outer drill tip 22, the inner drill tip 21 partially protrudes from the outer drill tip 22, and the cutting depth of the inner drill tip 21 is greater than the cutting depth of the outer drill tip 22 .

[0033] The drill tip 2 is composed of an inner drill tip 21 and an outer drill tip 22. The inner drill tip 21 and the outer drill tip 22 cut into the workpiece layer by layer in the direction of cutting depth. The inner drill tip 21 cuts into the workpiece first and then the outer drill tip 22 cuts into the workpiece , which prolongs the time for the drill tip 2...

Embodiment 2

[0042] Such as Figure 6 to Figure 9 As shown, the hole machining cutter of the present embodiment differs from Embodiment 1 in that:

[0043] The cutter body 1 and the outer drill tip 22 are made of the same material and are integral non-removable structures. The inner drill tip 21 is fixedly connected with the outer drill tip 22 by welding, and the drill tip 2 and the cutter body 1 form a fixed integral structure, so that there is no Additional fastening screws 15 are required.

[0044] In this embodiment, the cross section of the inner clearance surface 214 and the side wall surface of the countersink hole 224 are circular, and one side of the inner clearance surface 214 is tangent to the wall surface of the countersunk hole 224, and the other side is tangent to the wall surface of the countersink hole 224. The wall surfaces of 224 are clearance fit, and the maximum clearance of clearance fit is Y, which should satisfy 0.05mm≤Y≤0.3mm. There is an offset distance Z between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com