Patents

Literature

33results about How to "Reduced machinability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

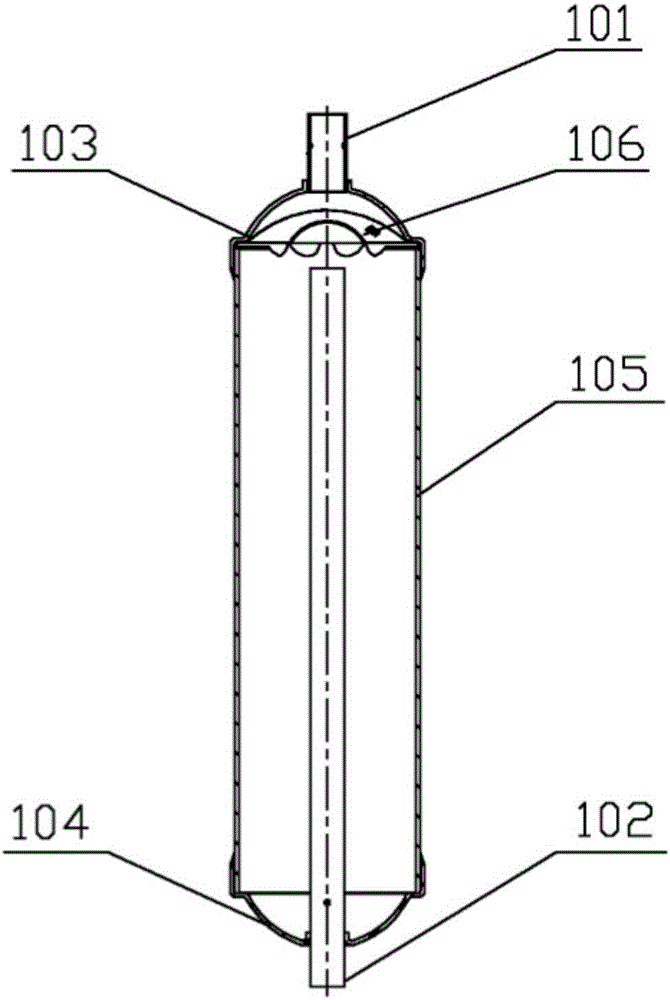

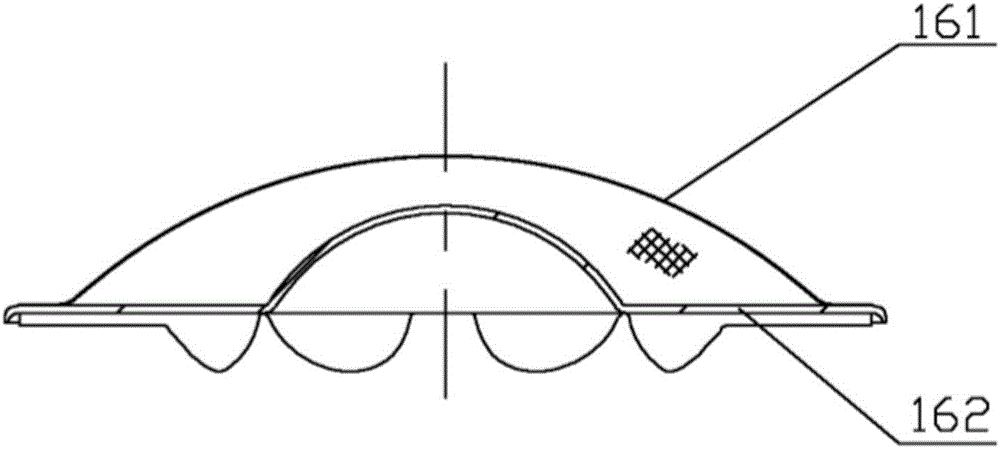

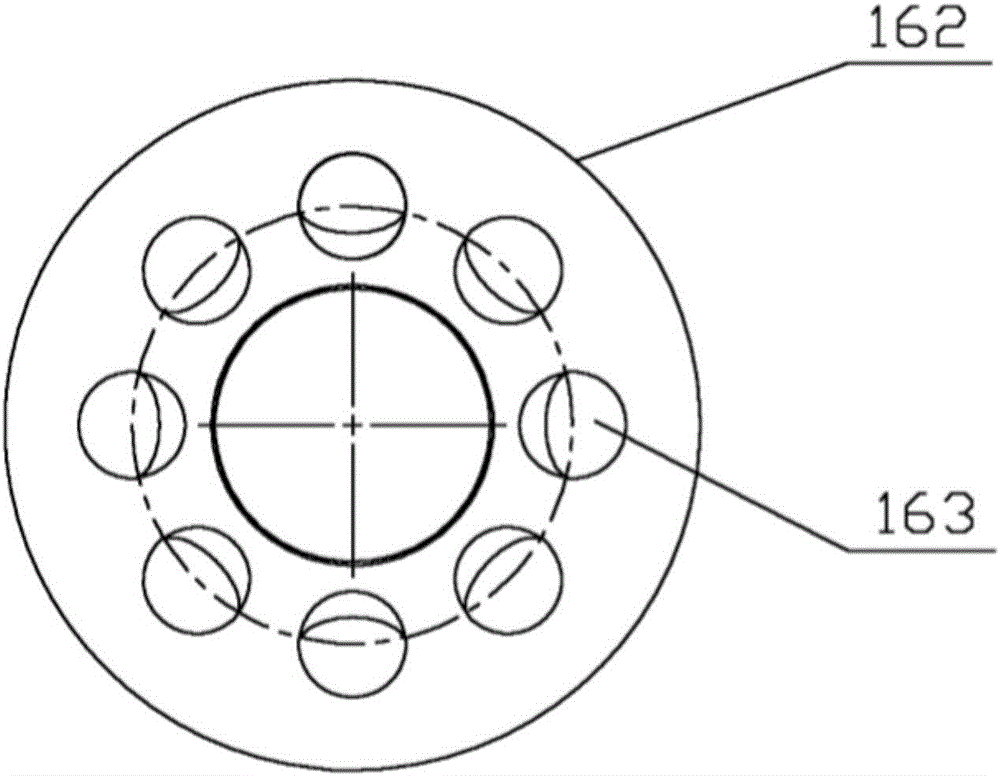

Gas-liquid separator

ActiveCN103245143AEfficient separationAvoid shockReversed direction vortexSuction cleanersVapor–liquid separatorEngineering

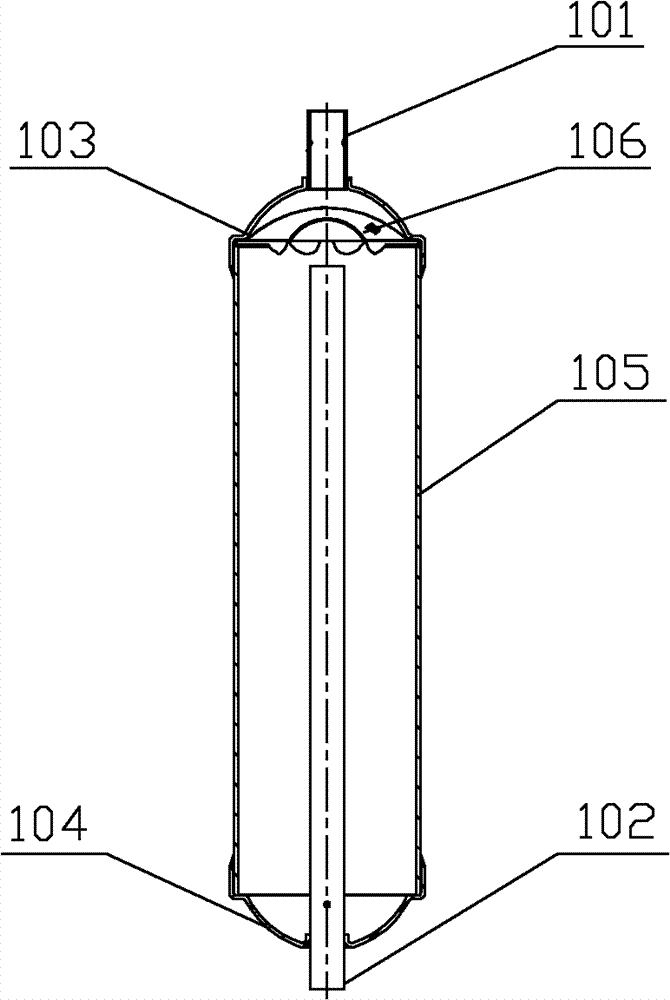

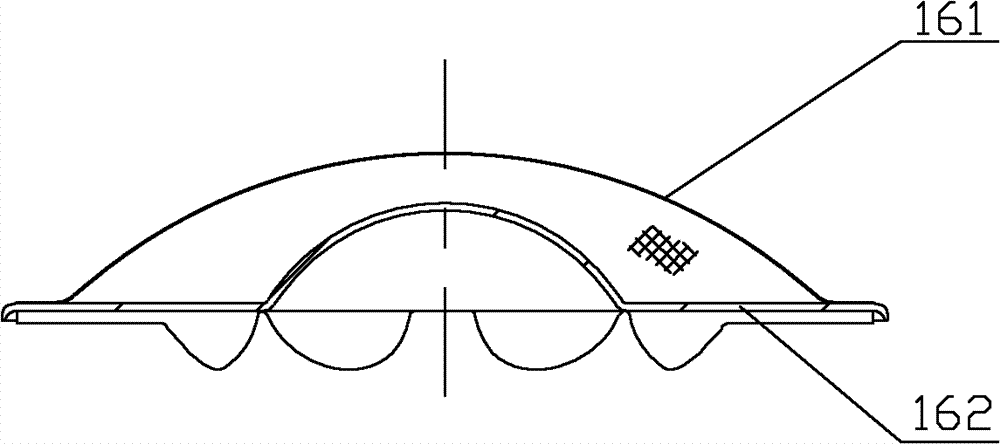

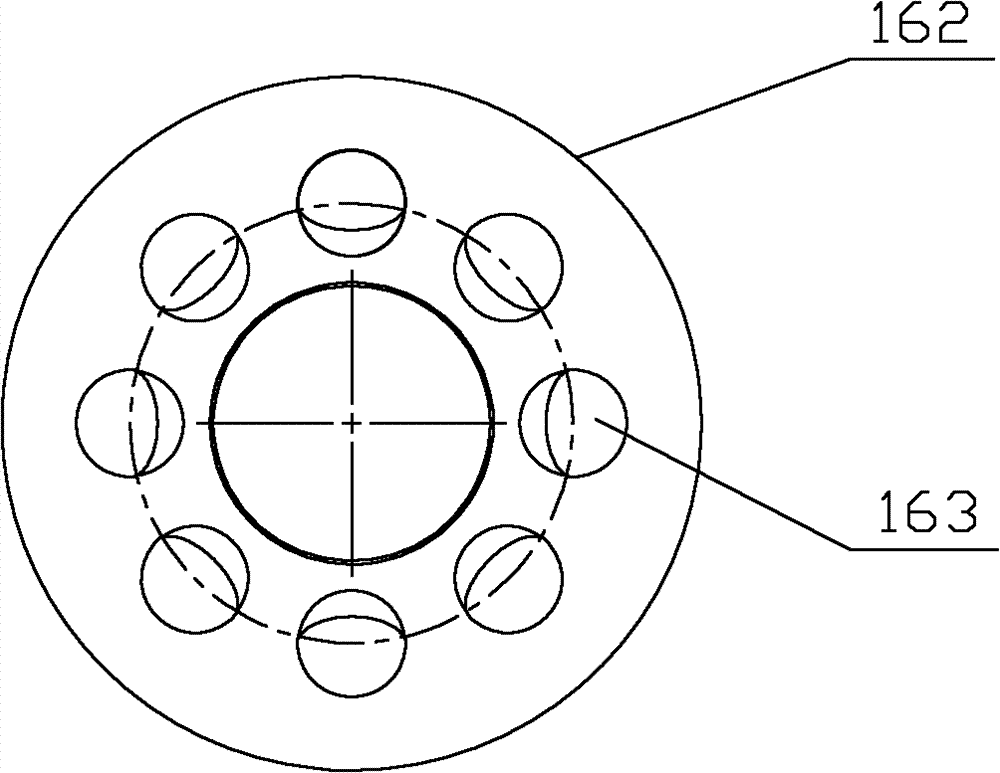

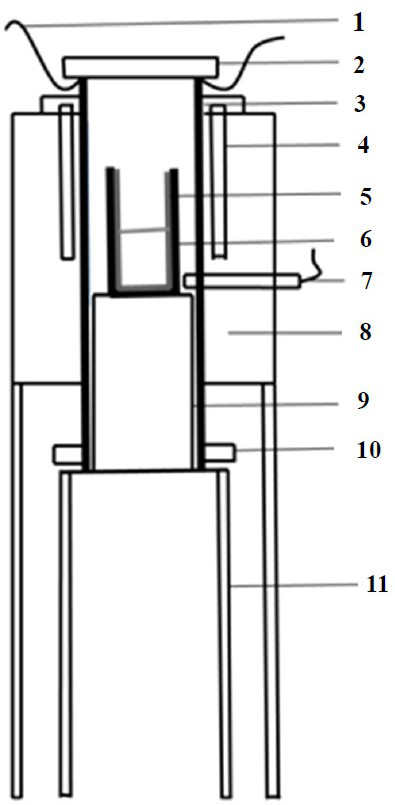

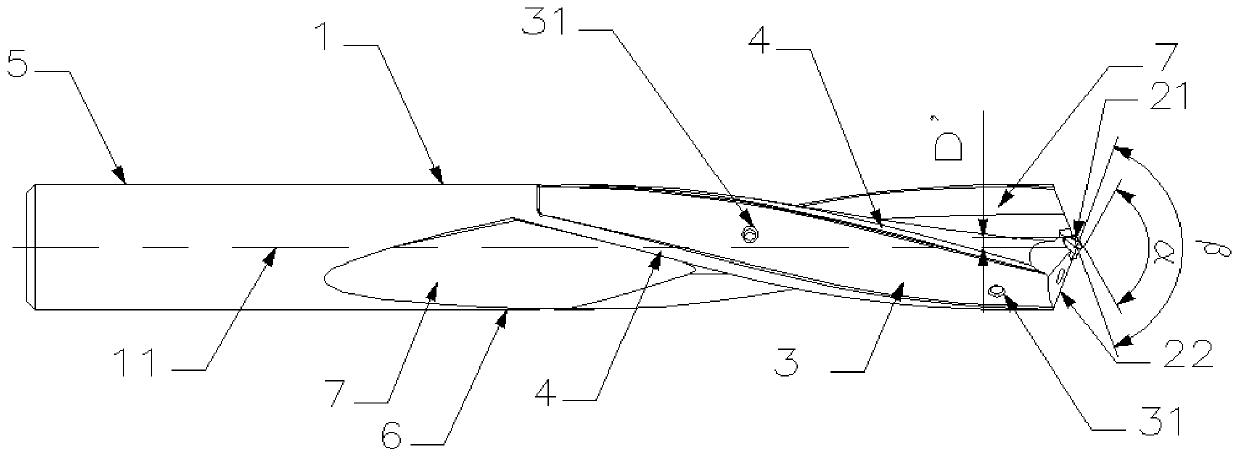

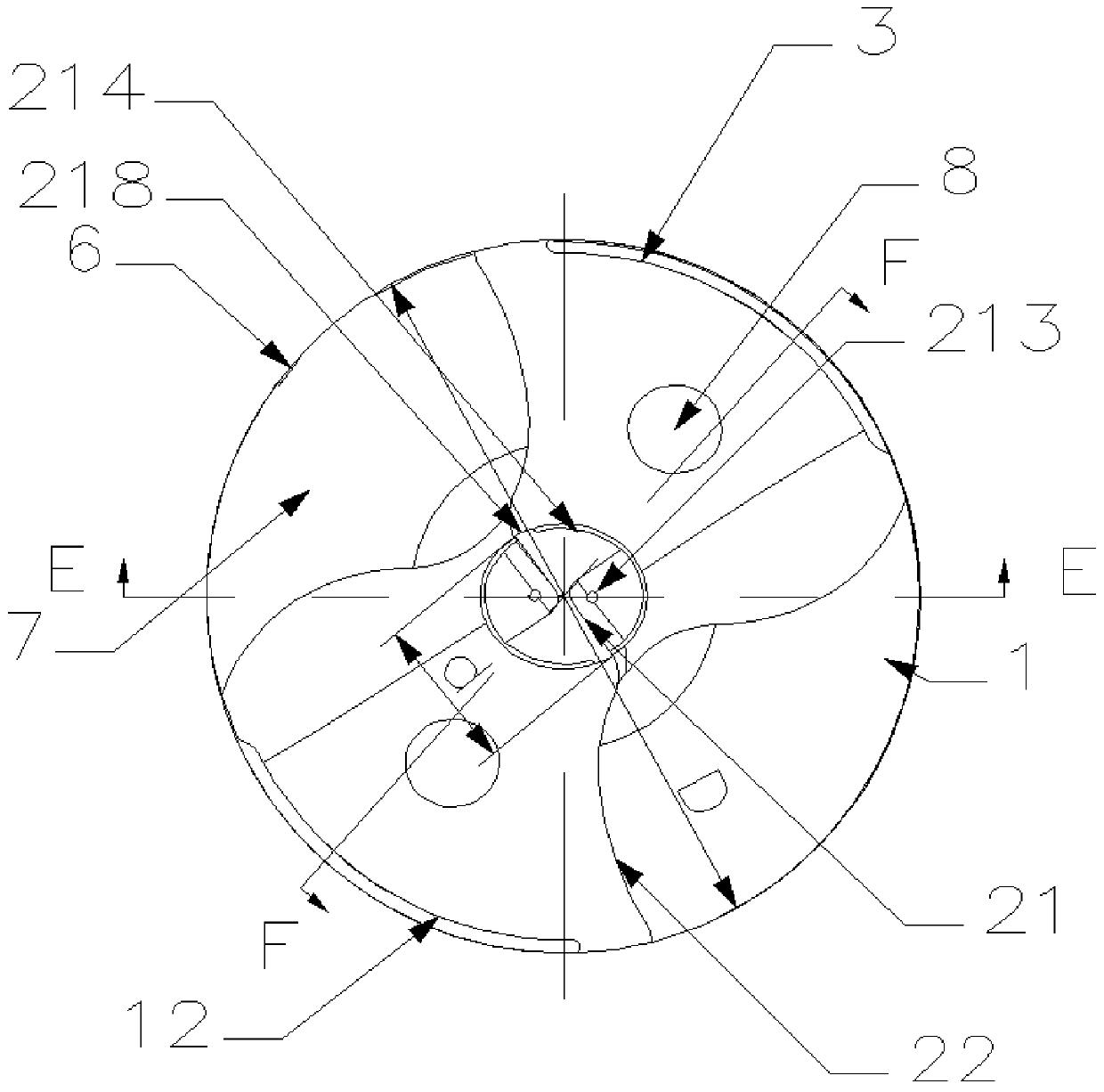

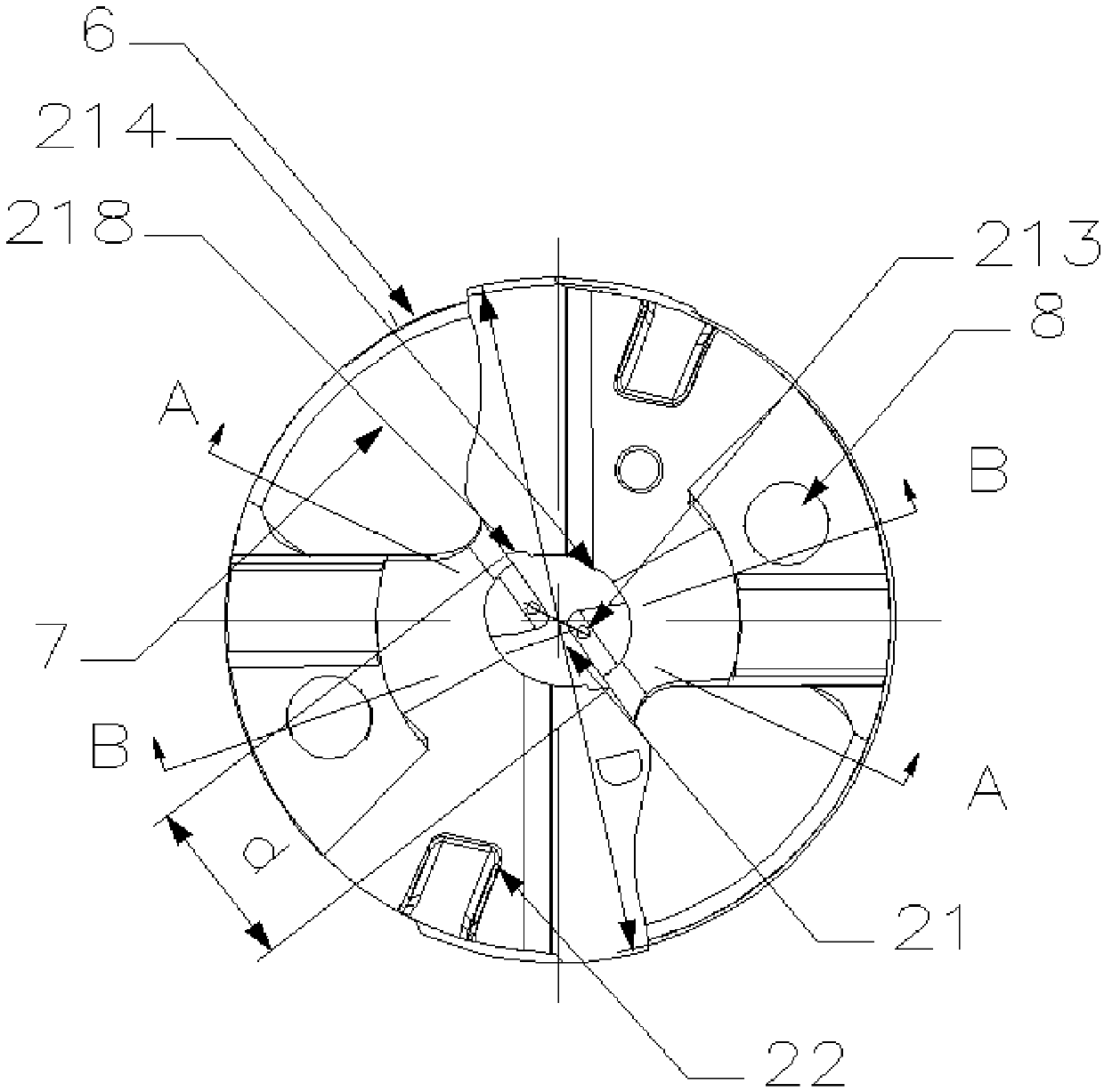

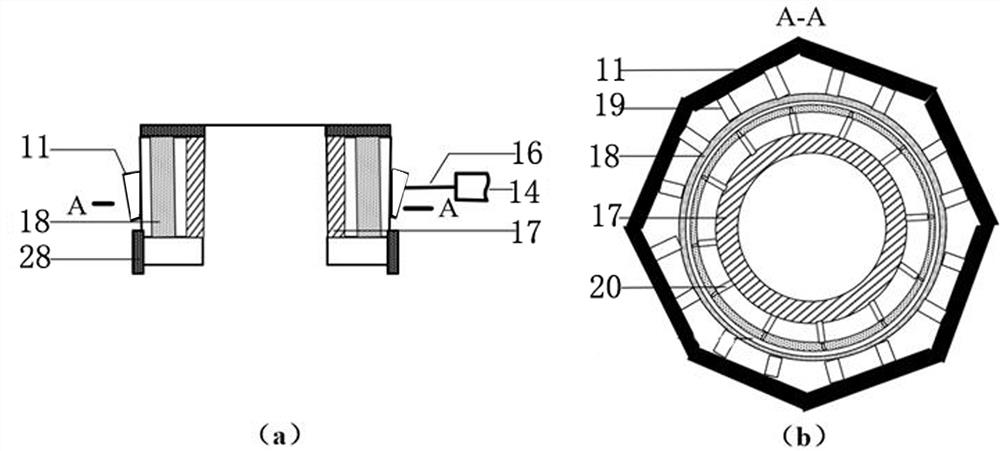

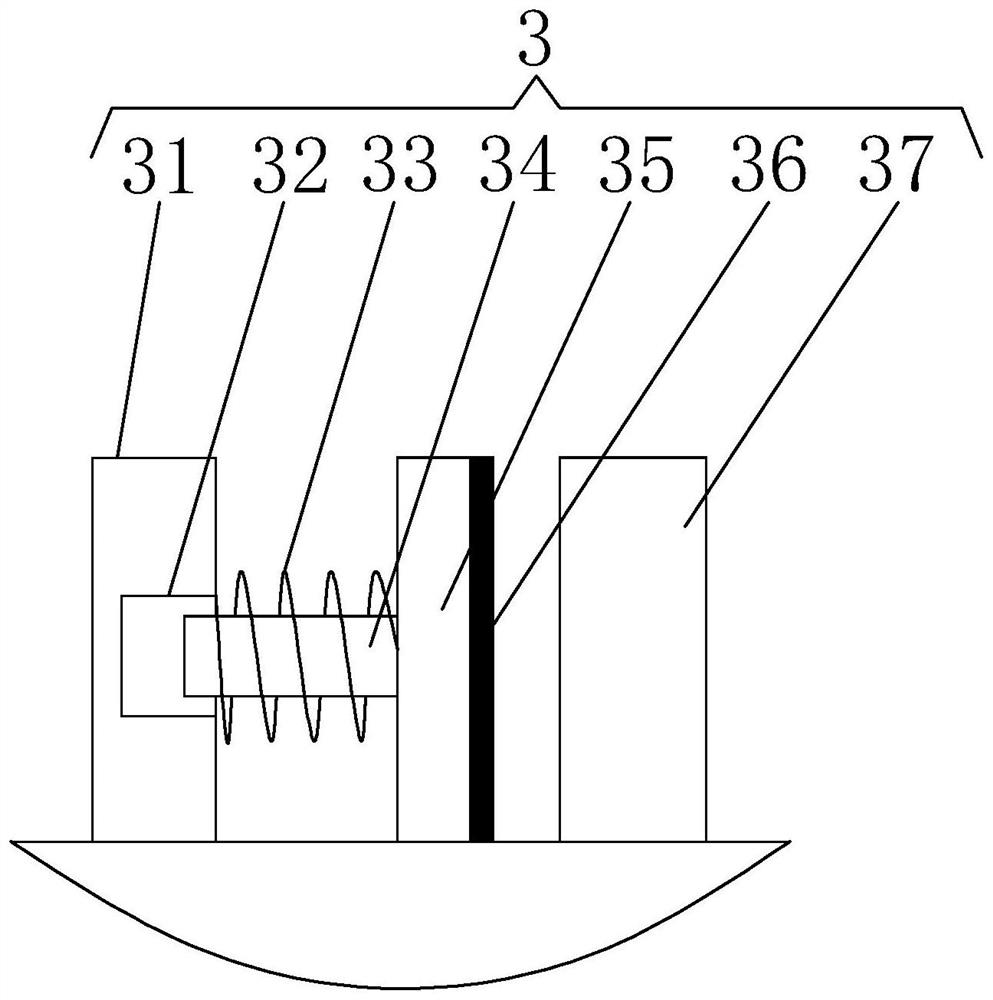

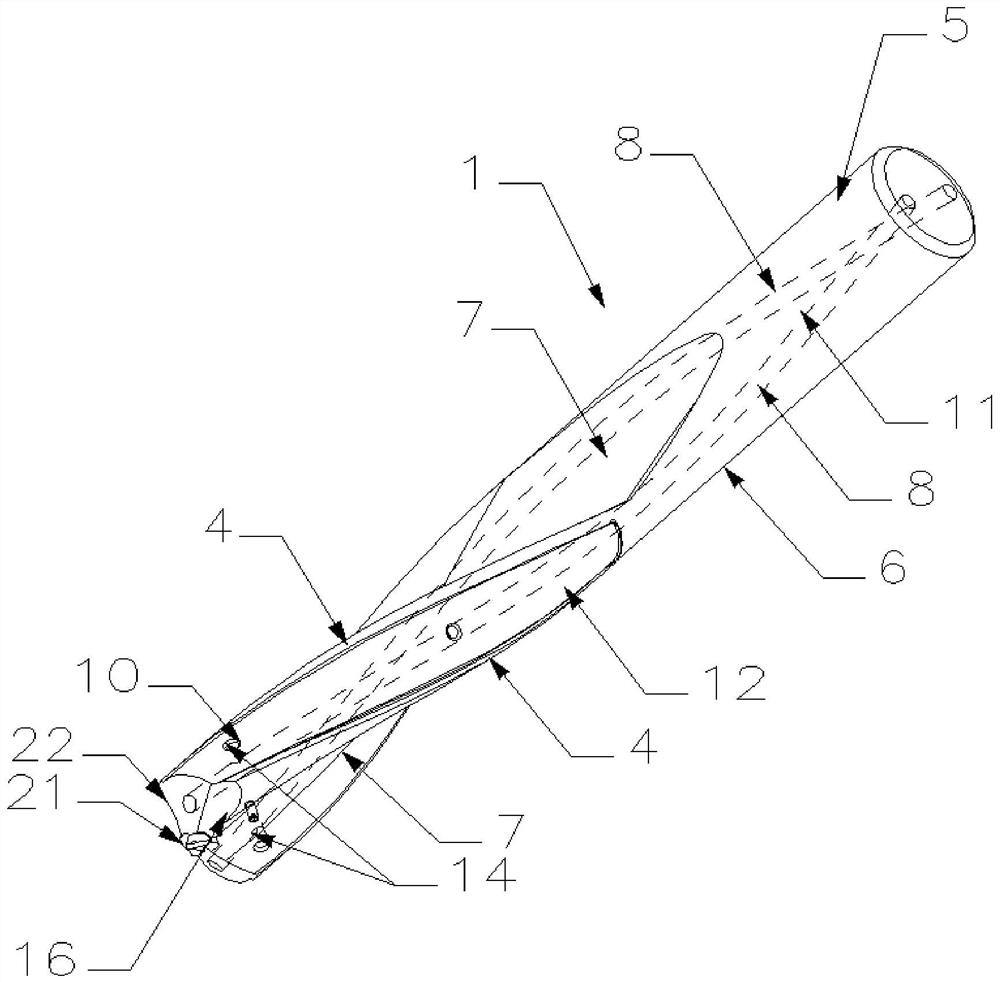

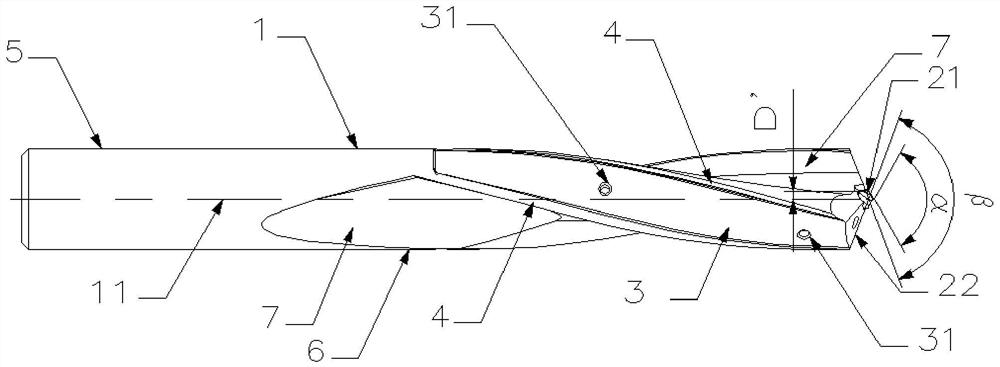

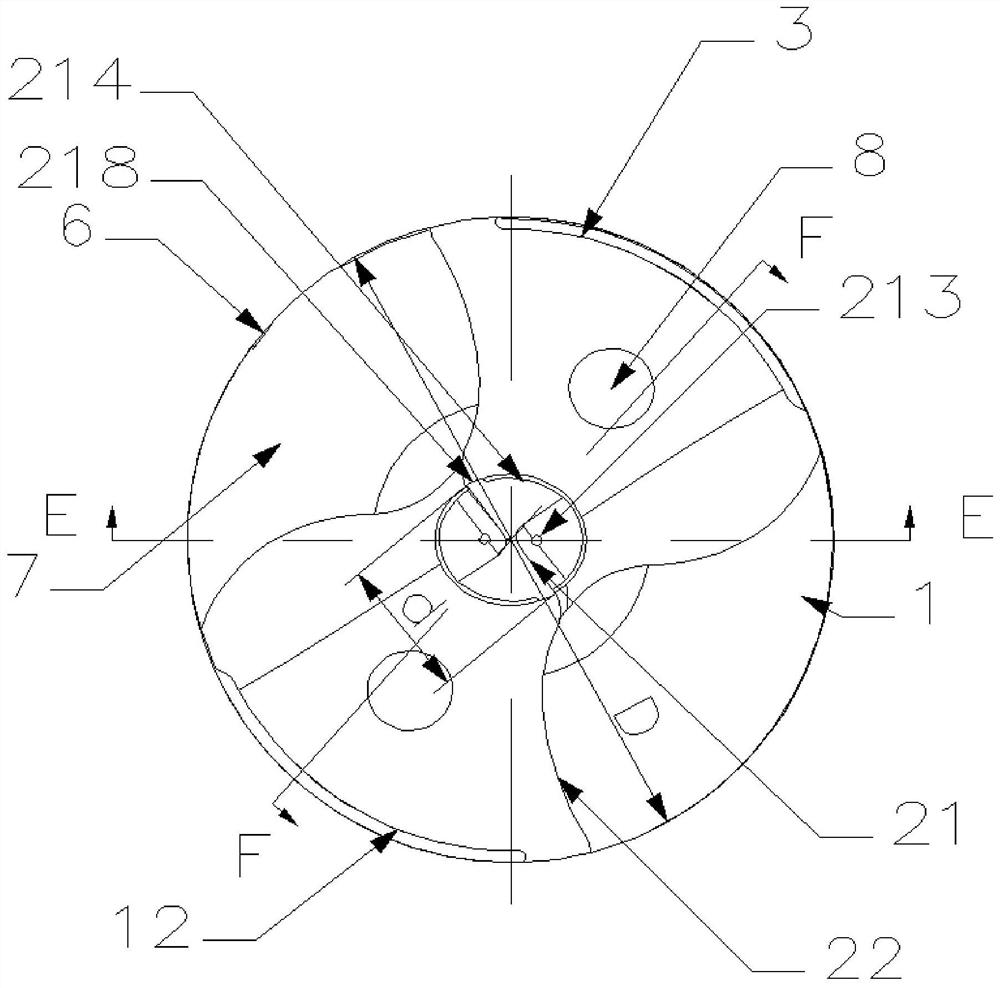

The invention discloses a gas-liquid separator used for a refrigerating system. The gas-liquid separator comprises a barrel, an inlet tube fixedly connected with the upper end of the barrel, a outlet tube fixedly connected with the lower end of the barrel, and a gas guiding element, wherein the gas guiding element further comprises a stop plate, a folding edge at one end of the stop plate and a baseplate at the other end of the stop plate, the stop plate is arranged above the outlet tube and shields a gas inlet of the outlet tube, the folding edge is fixedly connected with the inner wall of the barrel, and the baseplate is fixedly connected with the sidewall of a gas inlet end of the outlet tube. The gas guiding element is processed from a steel plate, is simple in processing technology, can effectively prevent liquid from entering the outlet tube so as to avoid liquid impact on a compressor, and can replace a positioning device to function in fixing the outlet tube.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

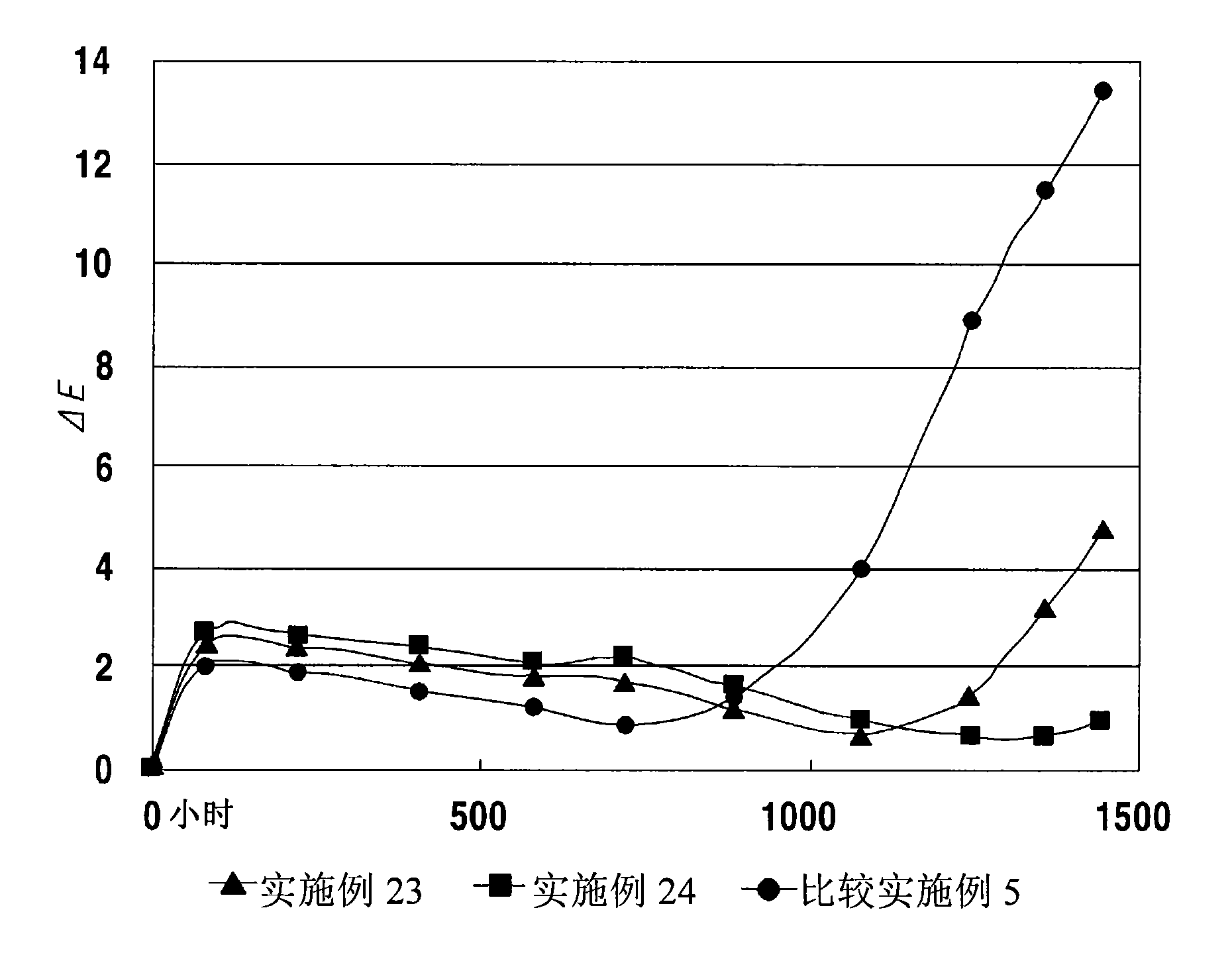

Low surface gloss styrene resin composition, low surface gloss sheet containing the same and preparing method thereof

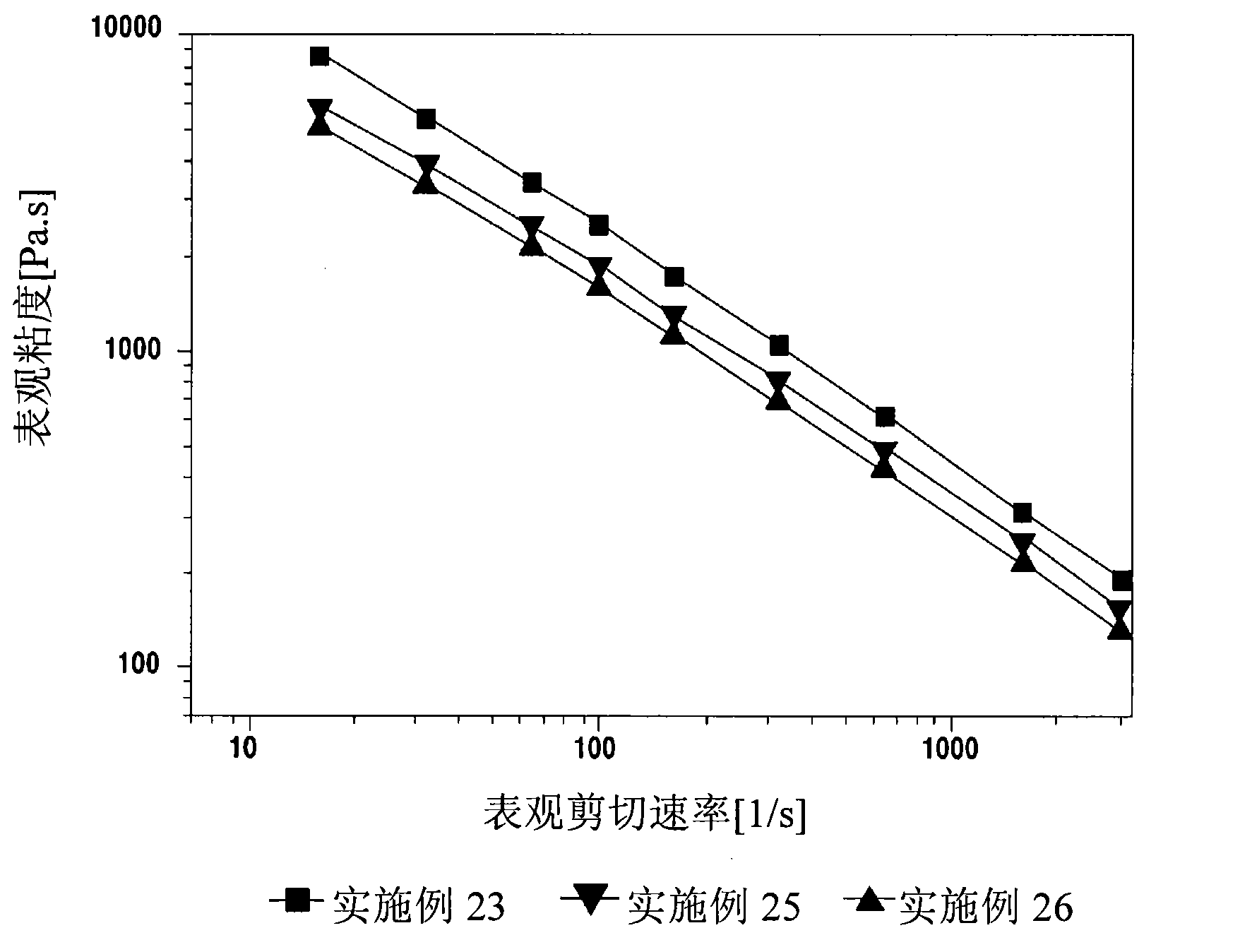

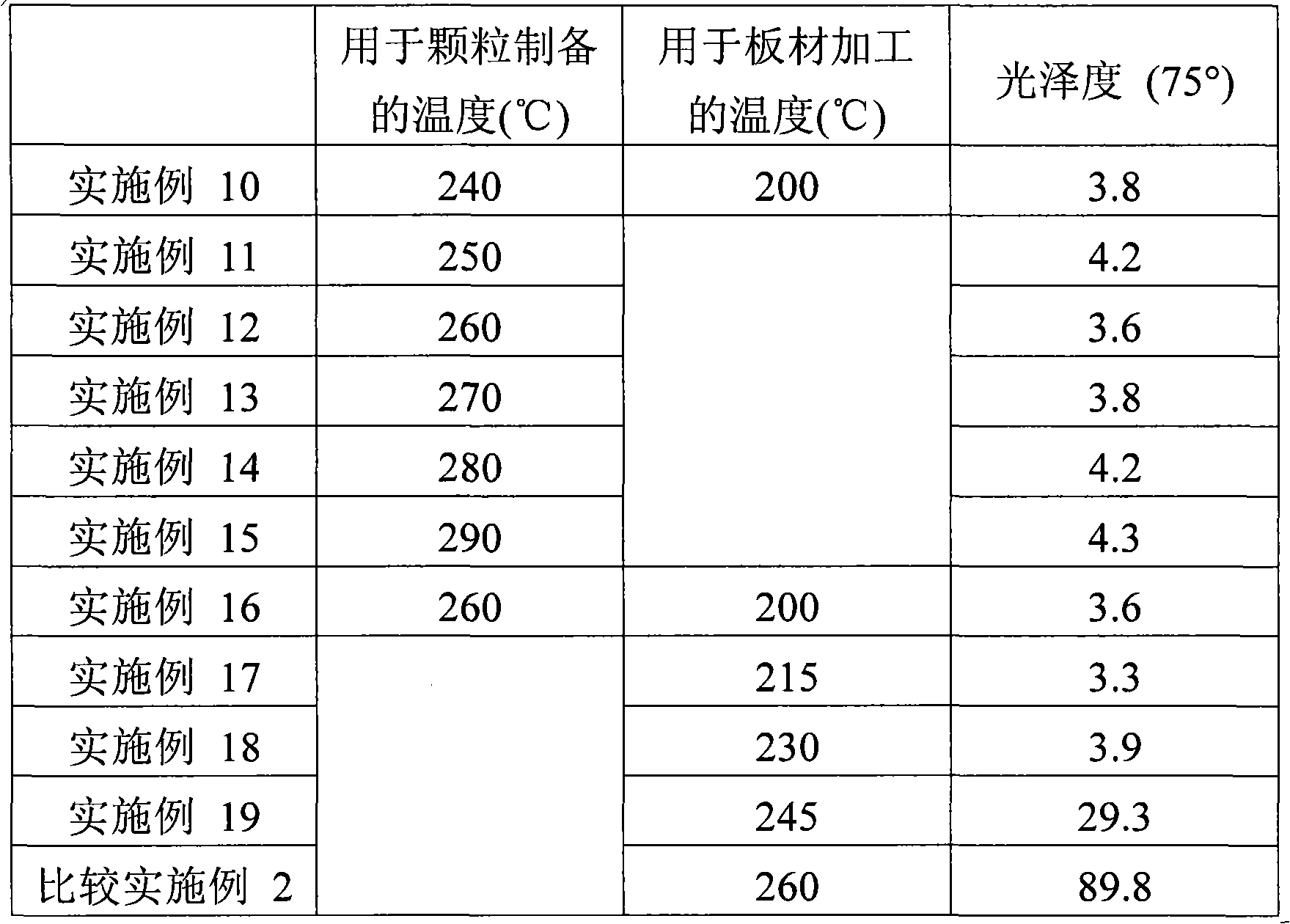

The present invention relates to a low surface gloss styrene resin composition. The composition of the present invention is composed of (A) 80-99.9 weight% of the basic resin comprising rubber-modified styrene resin and (B) 0.1-20 weight% of syndiotactic polystyrene, the matting agent. The composition also includes (C) hydrogenated styrene block copolymer comprising styrene block and butadiene rubber block as a compatibilizer by 0.1-20 weight% for the total weight of the low surface gloss styrene resin composed of (A) the basic resin and (B) the matting agent and additionally includes (D) a plasticizer by 0.1-30 weight%. The composition of the present invention has excellent weatherability and impact-resistance in addition to the low surface gloss properties, so that it can be applied in various products, particularly exterior products for structures such as sidings and window frames, etc.

Owner:LG CHEM LTD

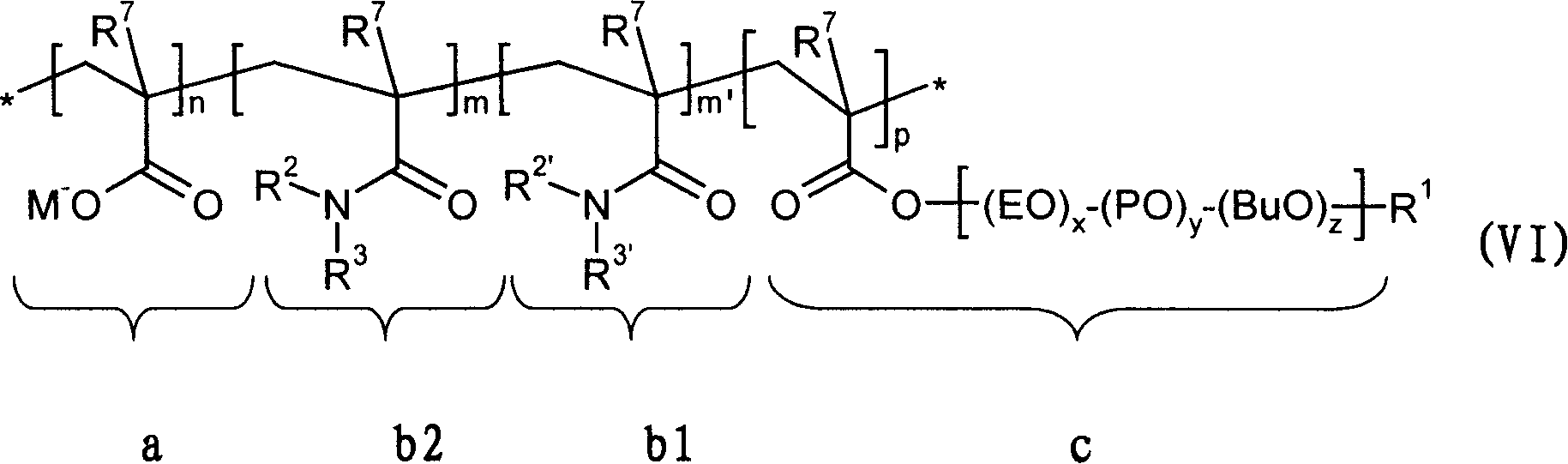

Polymer comprising amide and ester groups method for production and use thereof

One aspect of the invention relates to a process for the preparation of polymers P having amide groups and ester groups, wherein, in a first step, a homopolymer or copolymer P1 of (meth)acrylic acid is mixed with a monohydroxy compound E at a temperature of up to 200 °C, resulting in the formation of anhydride groups in addition to ester groups. In the second step, the anhydride groups formed in the first step are reacted with monoamine compound A at a temperature significantly lower than 100 °C. Another aspect of the invention relates to the polymer obtained according to the process, the use of the polymer in a hydraulic composition, and the hydraulic composition before and after hardening by water.

Owner:SIKA TECH AG

High-difficulty steel core wire electrode and manufacturing method thereof

InactiveCN105772878ALow tensile strengthImprove conductivityElectrical-based machining electrodesCopper wireHeat conducting

The invention discloses a high-difficulty steel core wire electrode and a manufacturing method thereof. The high-difficulty steel core wire electrode comprises a core material, a middle clad layer and an outer clad layer. The core material is prepared from raw materials including, by weight, 30-54 parts of iron, 30-55 parts of carbon, 1.5-2.4 parts of tin, 4-9 parts of chromium, 1-3 parts of manganese, 2-5 parts of molybdenum, 1.3-5.1 parts of nickel, 2.3-5.4 parts of silicon, 3-6 parts of tungsten, 3-4 parts of vanadium, 2-6 parts of phosphorus, 5-10 parts of sulphur and 12-15 parts of heat conducting filler. The steel core wire electrode is a composite wire and is composed of the steel core, the middle red copper clad layer and the outer brass clad layer. At the normal temperature, the steel core and a brass wire almost have the same tensile strength, but with the increase of temperature, the tensile strength of the brass wire is rapidly reduced, and the tensile strength of the steel is higher than that of the brass wire. The red copper layer is wrapped outside the steel core to improve the electric conductivity, and the outer brass layer plays a role in improving the washing performance.

Owner:尚成荣

Heat treatment method of steel

InactiveCN111139345AHigh hardnessImprove wear resistanceSolid state diffusion coatingIncreasing energy efficiencyFurnace temperatureTempering

The invention discloses a heat treatment method of steel. The heat treatment method of the steel comprises the following steps of (1) annealing, specifically, after a steel part is heated to enable the temperature to be Ac3+30-50 DEG C or Ac1+30-50 DEG C or below Ac1, the steel part is slowly cooled along with the furnace temperature; (2) normalization; (3) quenching; (4) tempering, specifically,the quenched steel part is heated again to enable the temperature to be below Ac1, and the steel part is cooled in the air or oil or hot water or water after heat preservation is accomplished; (5) hardening and tempering; (6) aging, specifically, the steel part is heated to enable the temperature to range from 80 DEG C to 200 DEG C, the heat preservation is conducted for 5-20 hours, and the steelpart is taken out and cooled in the air along with a furnace; (7) cold treatment; (8) flame heating surface quenching; (9) induction heating surface quenching; (10) carburization; (11) nitridation; and (12) nitrocarburizing. The hardness, the wear resistance, the fatigue strength and the corrosion resistance of the surface of the steel part are improved, the cutting machining performance is improved, and the smoothness of the machined surface is improved. The deformation and cracks formed in the quenching process are reduced, and the good comprehensive mechanical properties are obtained.

Owner:东台市宏凯不锈钢有限公司

Gas-liquid separator

InactiveCN106196769AEfficient separationAvoid shockRefrigeration componentsVapor–liquid separatorEngineering

The invention discloses a gas-liquid separator. The gas-liquid separator is used for a refrigerating system. The gas-liquid separator comprises a cylinder, an inlet pipe fixedly connected with the upper end of the cylinder and an outlet pipe fixedly connected with the lower end of the cylinder and further comprises a gas guide element; the gas guide element further comprises a baffle, a folding side located at one end of the baffle and a bottom plate located at the other end of the baffle; the baffle is located above the outlet pipe and shields a gas inlet of the outlet pipe, the folding side is fixedly connected with the inner wall of the cylinder, and the bottom plate is fixedly connected with the side wall of the gas inlet end of the outlet pipe. The gas guide element is formed by machining of a steel plate, the machining technology is simple, liquid can be effectively prevented from entering the outlet pipe, liquid hammer to a compressor is avoided, and the separator can replace a positioning device to a play a role in fixing the outlet pipe.

Owner:郭继安

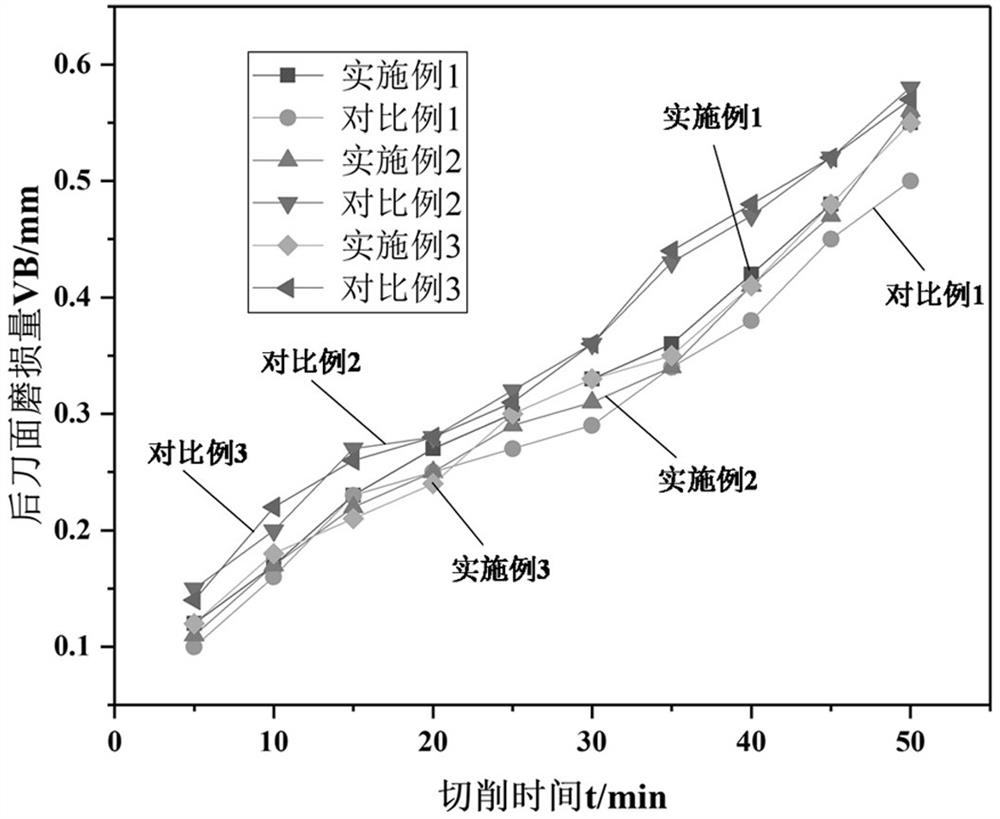

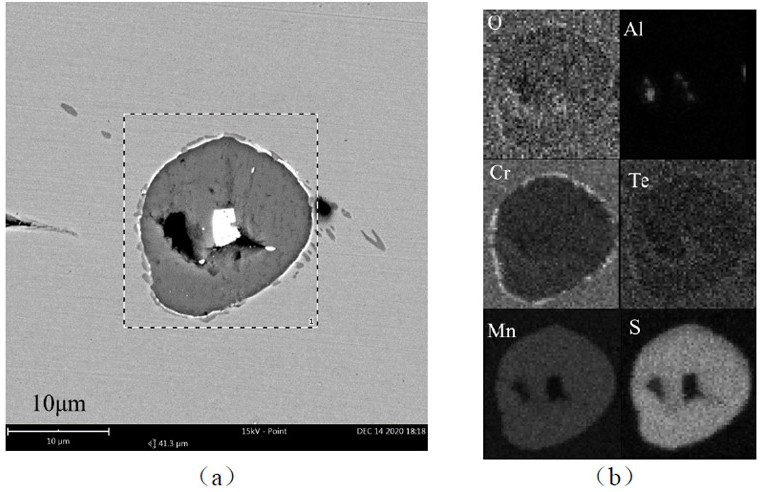

Free-cutting corrosion-resistant steel and preparation method thereof

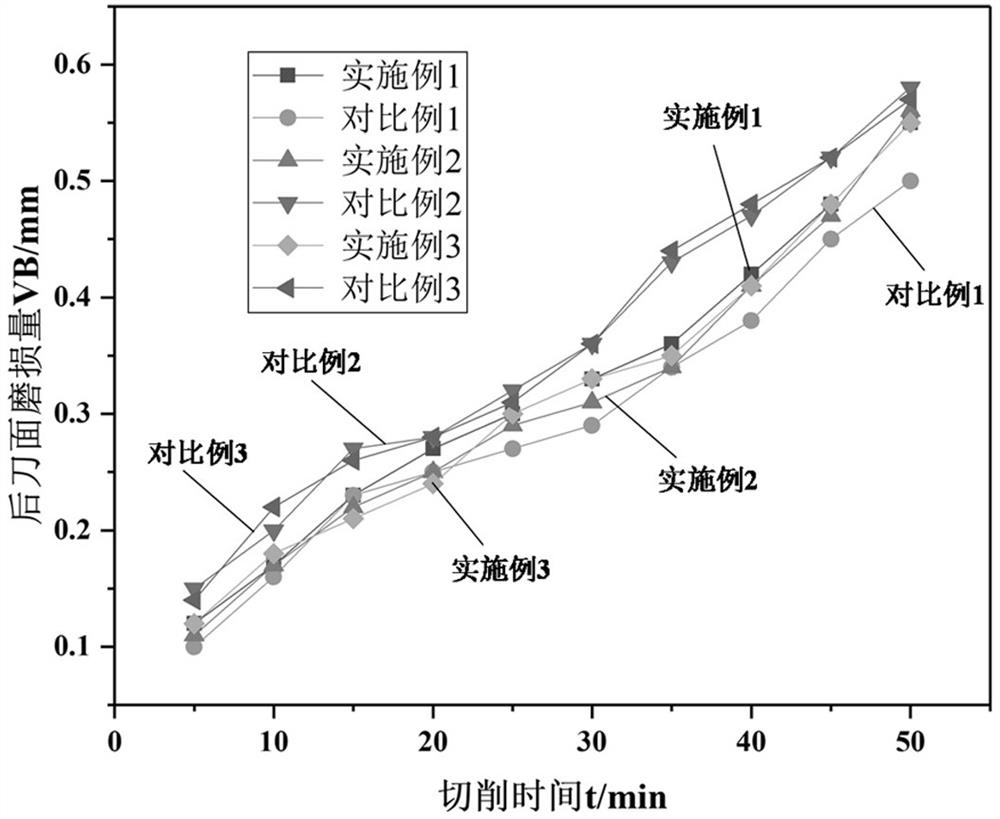

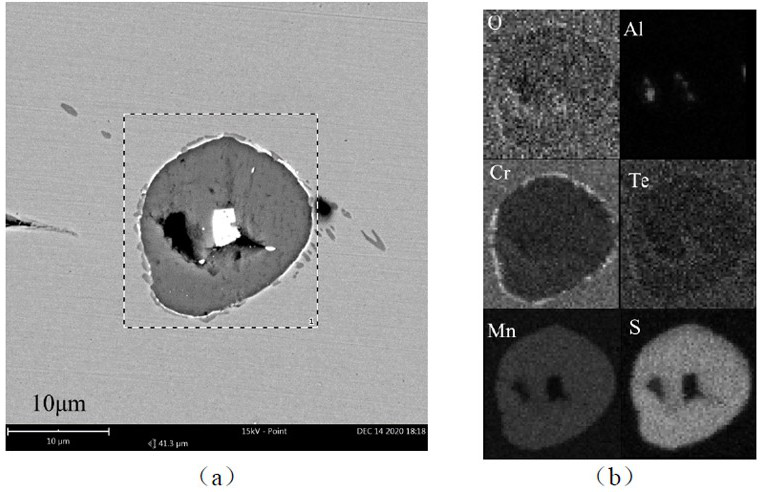

The invention relates to free-cutting corrosion-resistant steel and a preparation method thereof. The free-cutting corrosion-resistant steel comprises the following components in percentage by mass: 0.015 to 0.024 percent of C; 0.4 to 0.5 percent of Si; 1.2 to 1.3 percent of Mn; 0.24 to 0.3 percent of S; 0.02 to 0.03 percent of P; 1.5 to 1.75 percent of Mo; 19 to 20 percent of Cr; 0.03 to 0.08 percent of Ca; 0.01 to 0.02 percent of Mg; 0.02 to 0.05 percent of Al; 0.012 to 0.03 percent of Te; and the balance Fe and impurities. The method comprises the following steps of uniformly mixing free-cutting steel, a ferrochrome mixture and slag charge, and completely melting at high temperature to obtain a melt; and adding tellurium into the melt, conducting heat preservation treatment, and cooling to obtain the free-cutting corrosion-resistant steel. The free-cutting corrosion-resistant steel disclosed by the invention has the optimal component proportion, and has the comprehensive optimal free-cutting performance and corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING

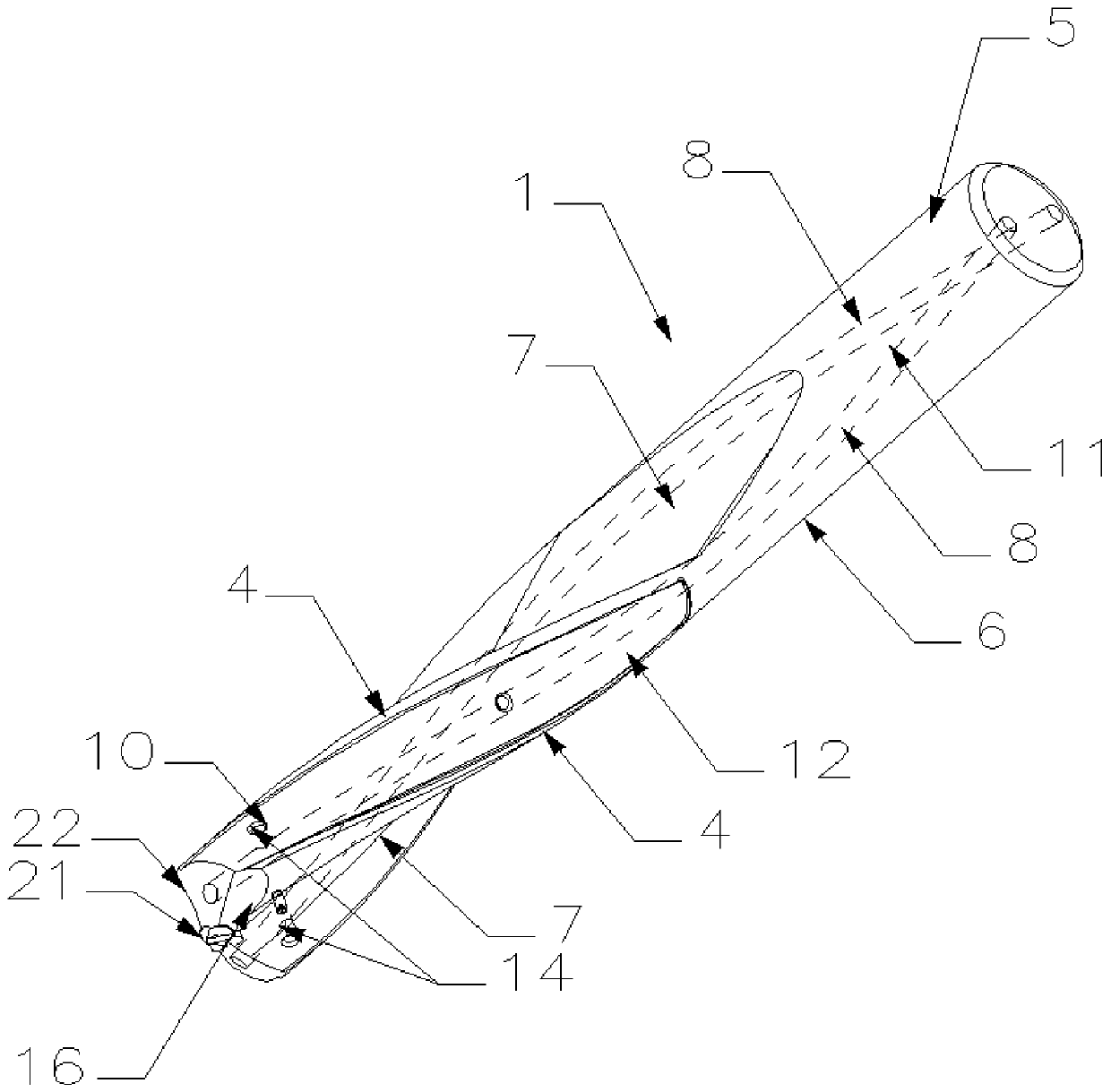

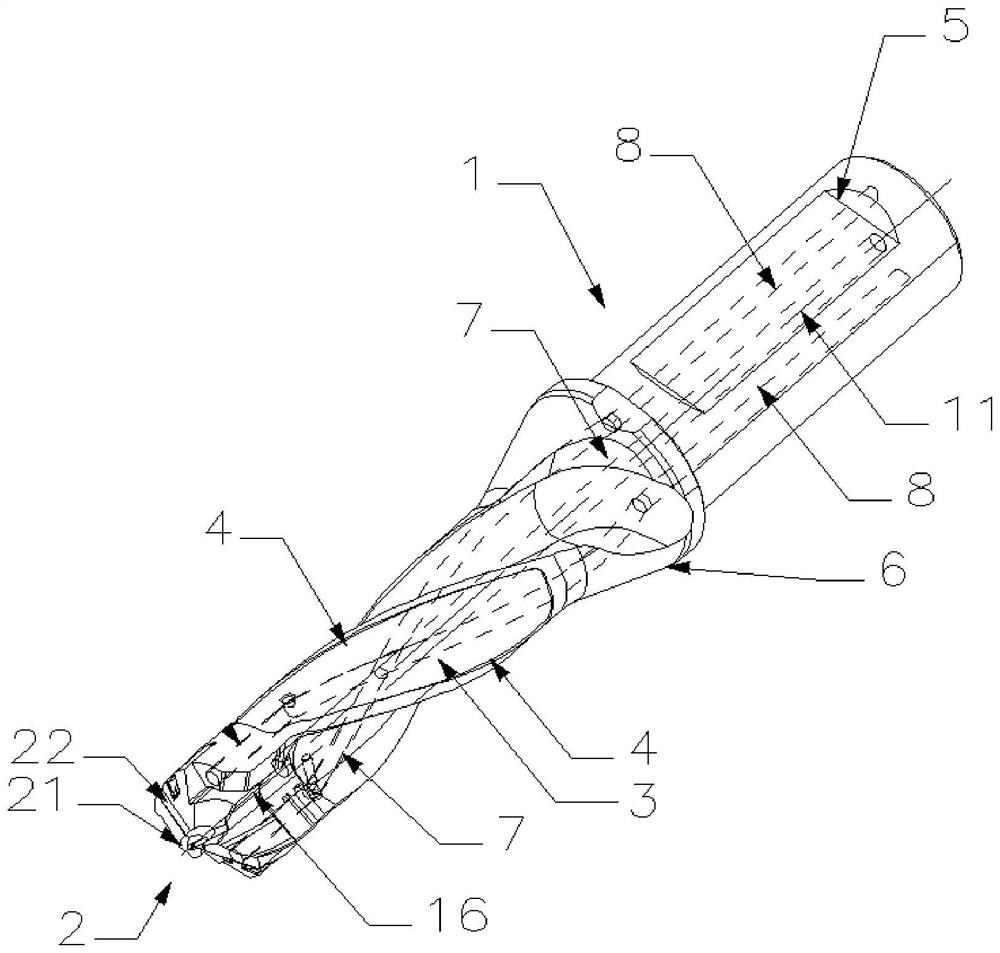

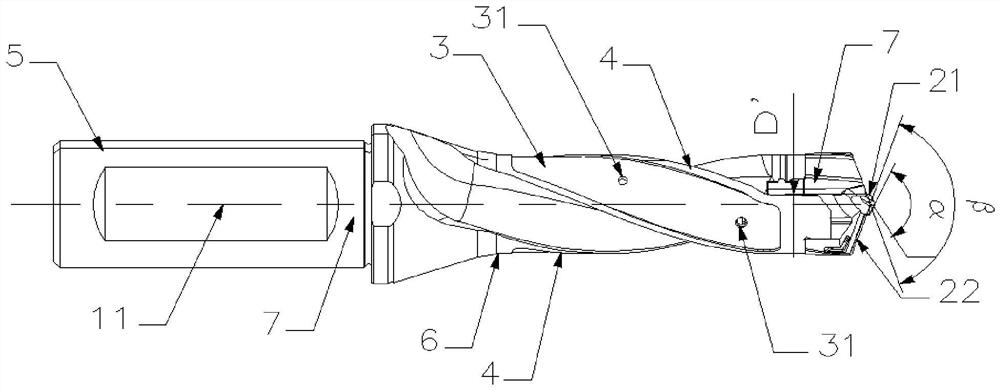

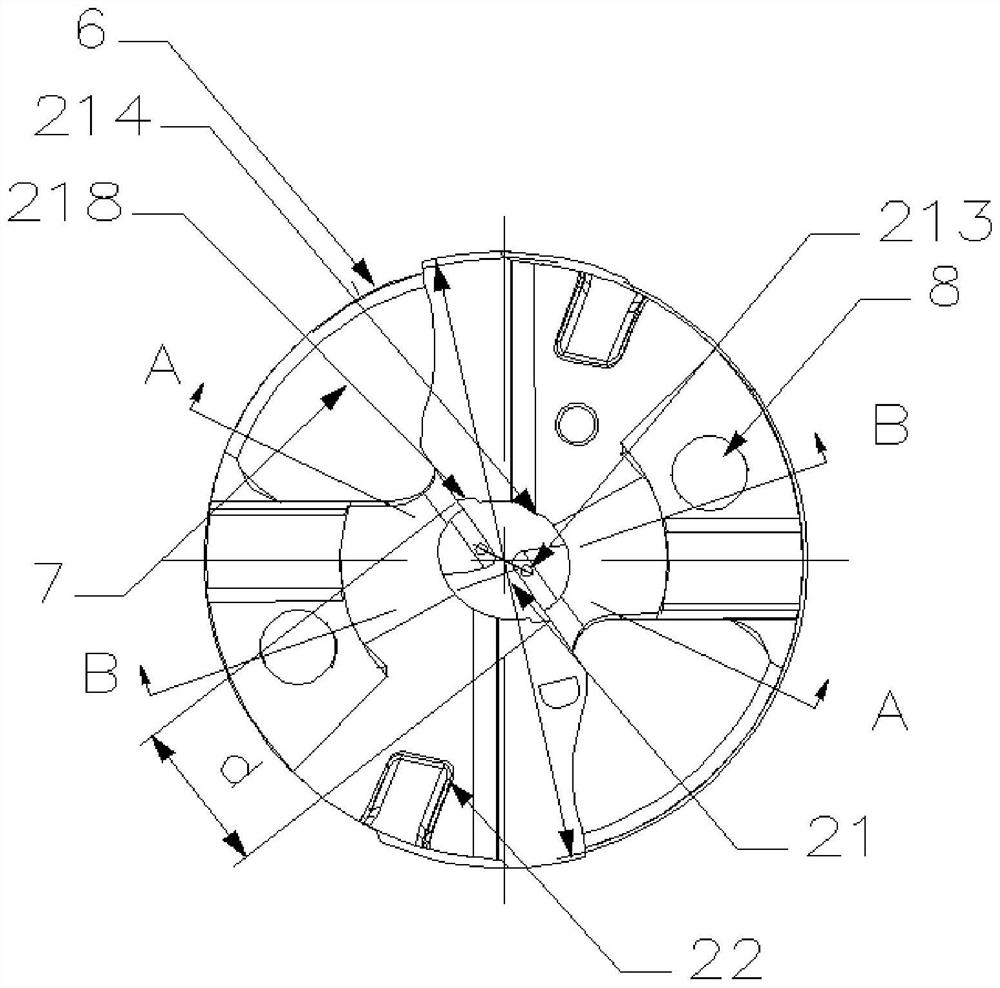

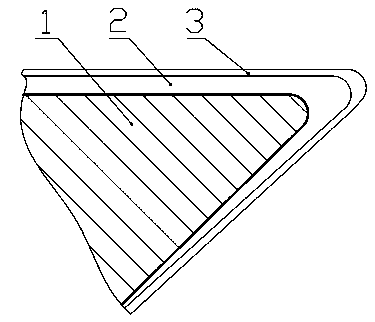

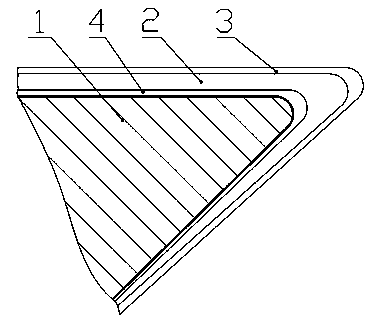

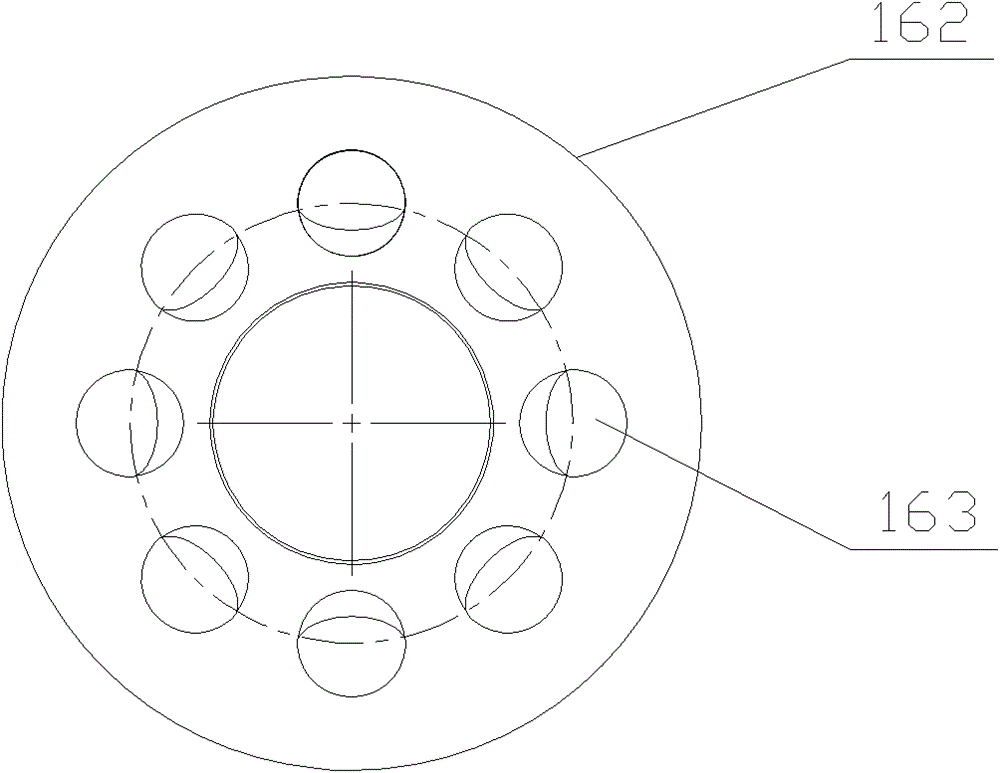

Hole machining tool with independent drill tip in center

ActiveCN109732127AImprove stabilityGuaranteed dimensional accuracyTransportation and packagingTrepanning drillsEngineeringDepth direction

The invention discloses a hole machining tool with an independent drill tip in the center. The hole machining tool comprises a tool body and the drill tip. The drill tip comprises an inner drill tip body and an outer drill tip body independent of each other. The outer drill tip body is arranged on the tool body. The inner drill tip body is mounted in the center of the outer drill tip body to forma core of the outer drill tip body. The cutting depth of the inner drill tip body is larger than that of the outer drill tip body. The drill tip is composed of the inner drill tip body and the outer drill tip body, the inner drill tip body is cut into a workpiece successively in a layered manner in the cutting depth direction, after the inner drill tip body is cut into the workpiece stably, the outer drill tip body is cut into the workpiece, the time that the drill tip is cut into the workpiece is prolonged, and the stability that the drill tip is drilled in the workpiece is greatly improved;due to the fact that the inner drill tip body is independent relative to the outer drill tip body, the inner drill tip body can have a small drill tip vertex angle, the outer drill tip body can have alarge drill tip vertex angle, the situation that the tool cut-in process is too fast and consequently a cutting edge is excessively extruded by cutting scraps can be avoided by means of the small drill tip vertex angle of the inner drill tip body, and stability generated when the drill tip is cut into the workpiece is improved; and the inner drill tip body can be mounted on the outer drill tip body in a batched interchanging manner and a flexible combination manner, and the inventory of the hole drilling tool is greatly reduced.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

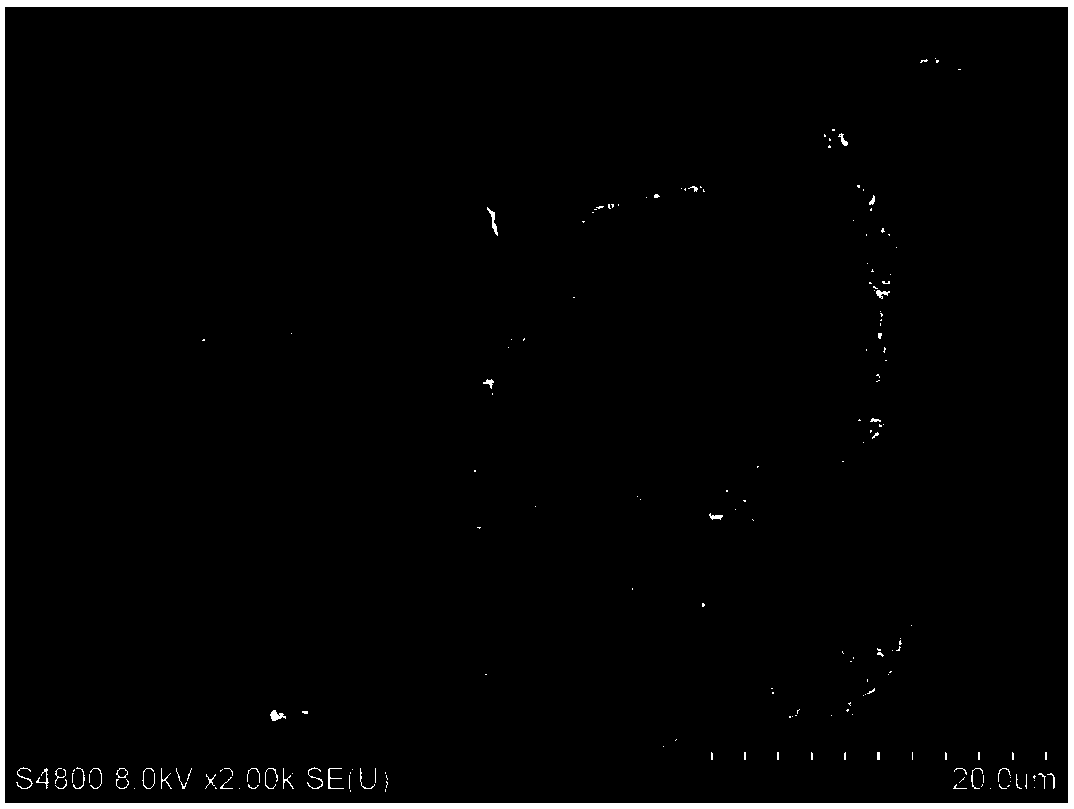

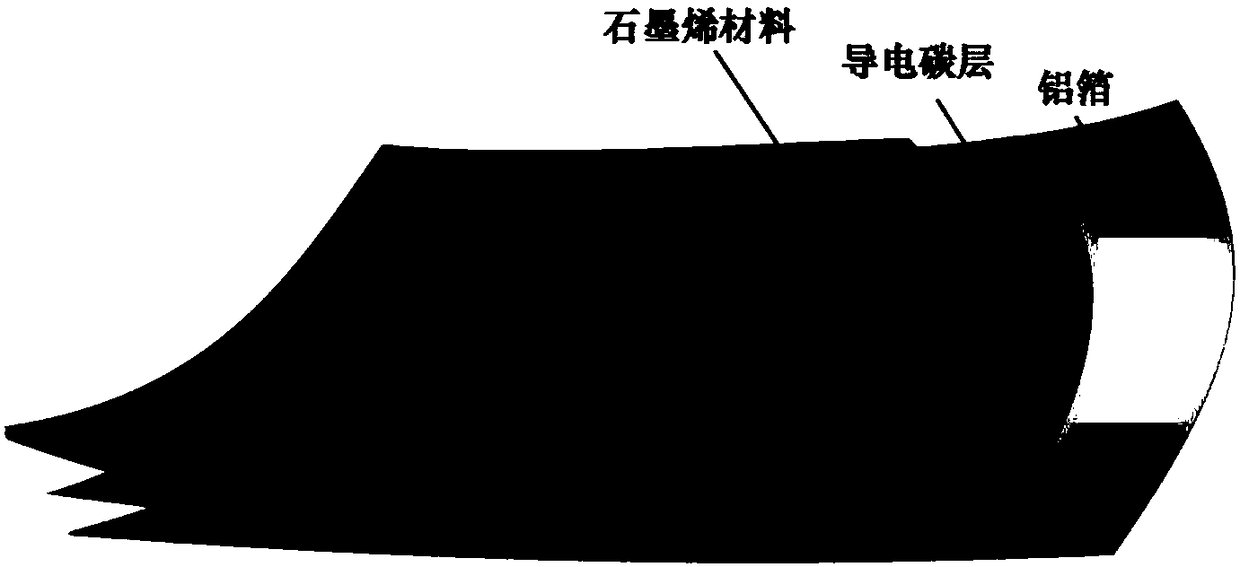

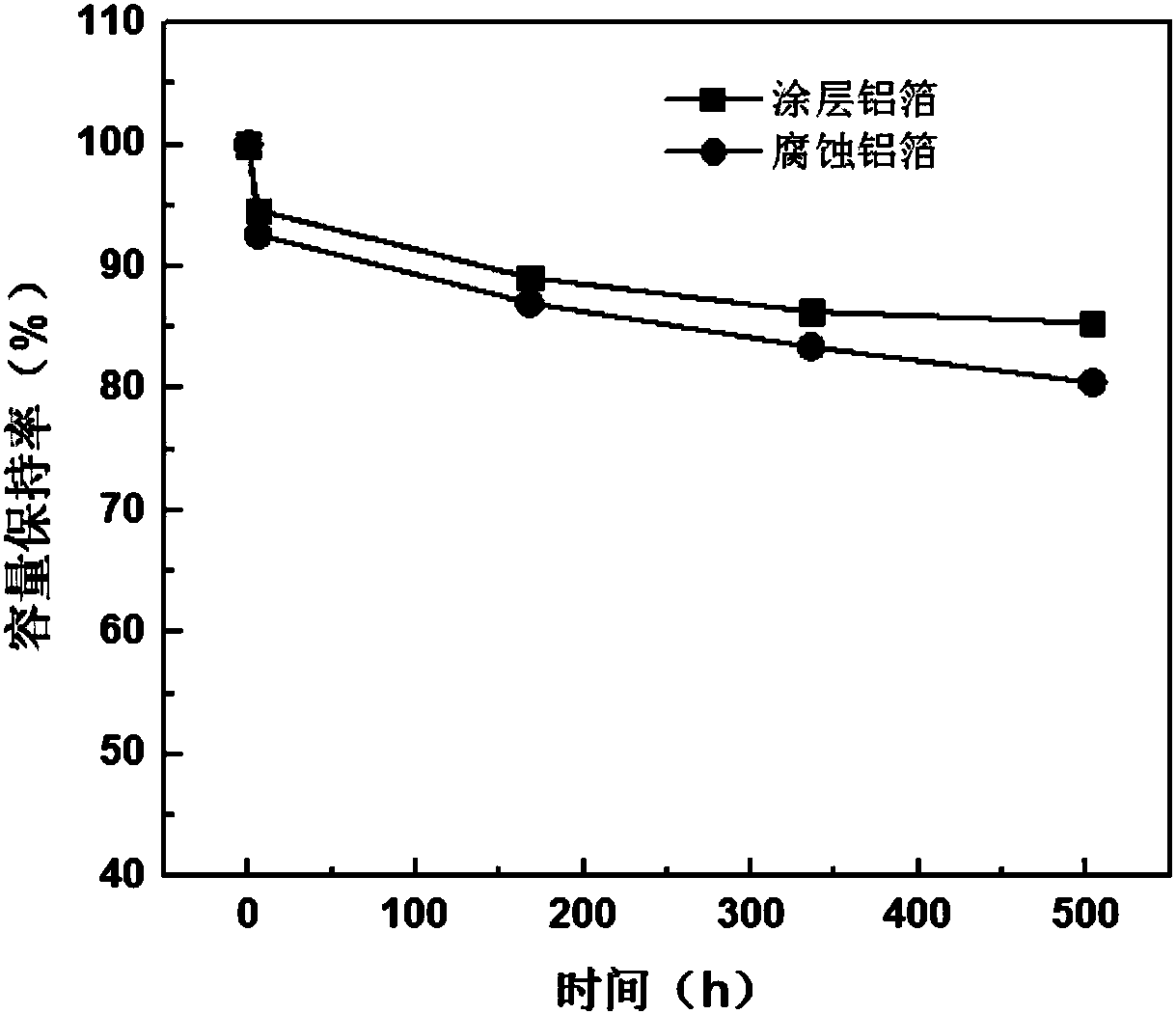

Low internal resistance and high power graphene super capacitor electrode sheet and manufacturing method

InactiveCN108470635ALarge specific surface areaImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureInternal resistanceNew energy

The invention relates to a graphene super capacitor electrode sheet, especially relates to a low internal resistance and high power graphene super capacitor electrode sheet and a manufacturing methodand belongs to the new energy storage device technology field. The graphene electrode sheet comprises a current collector and a graphene electrode slurry. The graphene electrode slurry comprises, by weight, 75-93% of graphene, 2-10% of conductive agent and 5-15% of binder. The current collector is a coating aluminum foil. The thickness of the graphene electrode sheet is 100-200 microns, and a surface density is 0.5-0.7g / cm<3>. The super capacitor graphene electrode sheet has characteristics of a low internal resistance, high power and the like.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

A kind of free-cutting corrosion-resistant steel and preparation method thereof

The invention relates to a free-cutting corrosion-resistant steel and a preparation method thereof. The free-cutting corrosion-resistant steel contains components in mass percentage: C, 0.015-0.024%; Si, 0.4-0.5%; Mn, 1.2-1.3%; S, 0.24-0.3%; P, 0.02-0.03% ; Mo, 1.5-1.75%; Cr, 19-20%; Ca, 0.03-0.08%; Mg, 0.01-0.02%; Al, 0.02-0.05%; Te, 0.012-0.03%; the balance is Fe and impurities. The method comprises the following steps: mixing free-cutting steel, chromium-ferro mixed material and slag material, and completely melting at high temperature to obtain molten material; adding tellurium to the molten material, heat preservation treatment, and cooling to obtain easy-cutting corrosion-resistant steel. The free-cutting corrosion-resistant steel in the invention has the best composition ratio, and has the best comprehensive free-cutting performance and corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING

A Hole Machining Tool with an Independent Drill Point in the Center

ActiveCN109570576BImprove stabilityGuaranteed dimensional accuracyTransportation and packagingTrepanning drillsStructural engineeringMachine tool

The invention discloses a hole-machining tool with an independent drill tip in center. The hole-machining tool with the independent drill tip in center comprises a tool body and the drill tip, the drill tip comprises an inner drill tip and an outer drill tip which are independent from each other, the outer drill tip is arranged on the tool body, the inner drill tip is arranged at the center of theouter drill tip in a penetrating mode and is arranged on the tool body, and the cutting depth of the inner drill tip is larger than the cutting depth of the outer drill tip. The drill tip is composedof the inner drill tip and the outer drill tip, the inner drill tip and the outer drill tip sequentially cut into a workpiece in a layered mode along the cutting depth direction, the inner drill tipcuts into the workpiece stably and then the outer drill tip cuts into the workpiece, so that the time for the drill tip to cut into the workpiece is prolonged and the stability of the drill tip duringdrilling into the workpiece is greatly improved; due to the fact that the inner drill tip is independent from the outer drill tip, the inner drill tip is provided with a small drill tip angle, the outer drill tip is provided with a large drill tip angle, the tool can be prevented from drilling excessively fast in the cut-in process, so that excessive extrusion to cutting edges by cut chips can beprevented, and the stability of the tool during cutting into the workpiece is improved; and the inner drill tips can be interchanged in batches, flexibly combined and installed on the outer drill tip, so that the inventory of hole drilling tools is greatly reduced.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

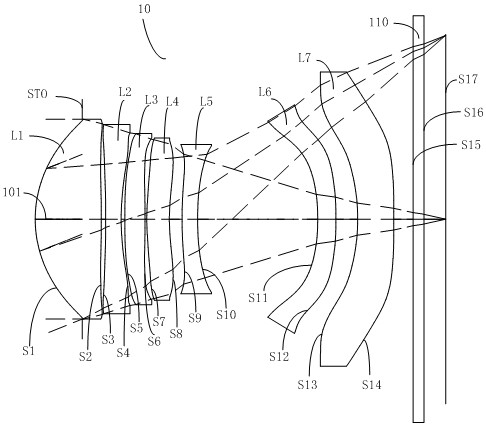

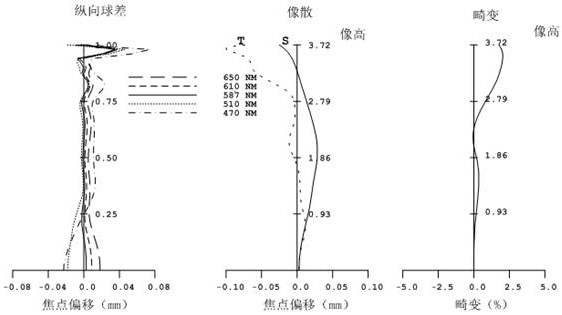

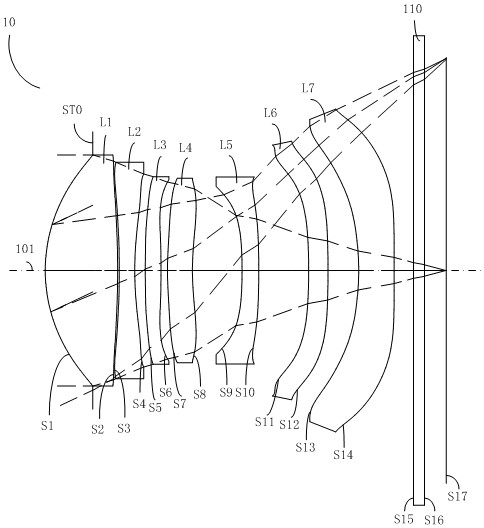

Optical system, camera module and electronic equipment

The invention discloses an optical system, a camera module and electronic equipment. The optical system includes: a first lens element with positive refractive power having an object-side surface being convex in a paraxial region thereof; the object-side surface and the image-side surface of the second lens are respectively a convex surface and a concave surface near the circumference, the object-side surface of the third lens is a convex surface near the optical axis, and the image-side surface of the third lens is a concave surface near the circumference; the fourth lens, the fifth lens, the sixth lens and the seventh lens have refractive power; the object side surface of the fifth lens is a concave surface near the circumference; the sixth lens element has an object-side surface being concave in a paraxial region thereof. The object side surface and the image side surface of the seventh lens are respectively a concave surface and a convex surface near the circumference; the optical system satisfies the relationship 0.242 mm <-1 > < (TTL / ImgH) / f < 0.261 mm <-1 >. According to the optical system provided by the embodiment of the invention, good imaging quality can be considered while miniaturization design is realized.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

Hole-machining tool with independent drill tip in center

ActiveCN109570576AImprove stabilityGuaranteed dimensional accuracyTransportation and packagingTrepanning drillsEngineeringDepth direction

The invention discloses a hole-machining tool with an independent drill tip in center. The hole-machining tool with the independent drill tip in center comprises a tool body and the drill tip, the drill tip comprises an inner drill tip and an outer drill tip which are independent from each other, the outer drill tip is arranged on the tool body, the inner drill tip is arranged at the center of theouter drill tip in a penetrating mode and is arranged on the tool body, and the cutting depth of the inner drill tip is larger than the cutting depth of the outer drill tip. The drill tip is composedof the inner drill tip and the outer drill tip, the inner drill tip and the outer drill tip sequentially cut into a workpiece in a layered mode along the cutting depth direction, the inner drill tipcuts into the workpiece stably and then the outer drill tip cuts into the workpiece, so that the time for the drill tip to cut into the workpiece is prolonged and the stability of the drill tip duringdrilling into the workpiece is greatly improved; due to the fact that the inner drill tip is independent from the outer drill tip, the inner drill tip is provided with a small drill tip angle, the outer drill tip is provided with a large drill tip angle, the tool can be prevented from drilling excessively fast in the cut-in process, so that excessive extrusion to cutting edges by cut chips can beprevented, and the stability of the tool during cutting into the workpiece is improved; and the inner drill tips can be interchanged in batches, flexibly combined and installed on the outer drill tip, so that the inventory of hole drilling tools is greatly reduced.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

A kind of cutting tool with superhard film coating and its preparation method

InactiveCN102649331BReduce roughnessImprove the finishVacuum evaporation coatingSputtering coatingCarbon filmMicron scale

The invention discloses a cutting tool with a superhard film coating and a preparation method thereof. The cutting tool includes a cutting tool substrate and a coating deposited on the cutting tool substrate; the coating includes a micron-order superhard film and a nano-order superhard film; The superhard film is directly deposited on the surface of the tool substrate; the nanoscale superhard film is deposited on the surface of the micron superhard film; the superhard film is selected from crystalline carbon nitride film or crystalline cubic boron nitride film. The composite coating prepared by the invention has the advantages of smooth surface, low friction coefficient, high hardness, high wear resistance, and good adhesion to the tool matrix. The coated tool is not only suitable for processing non-ferrous metals, non-ferrous alloys, non-metallic materials, but also for processing steel and other materials; it is not only suitable for semi-finishing, but also suitable for finishing.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

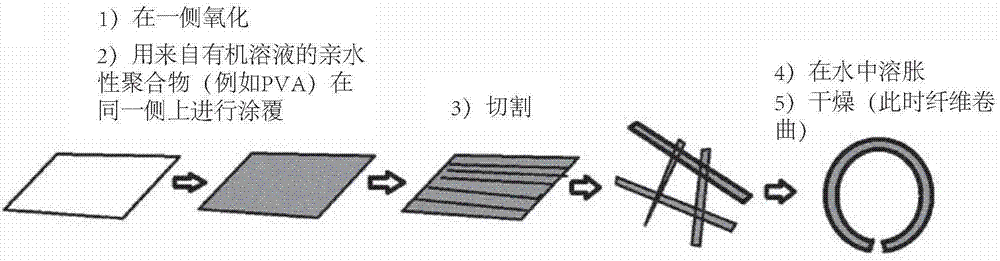

Composite fiber for inorganic binder applications

ActiveCN107531571AReduce liquidityReduced processing performanceFilament/thread formingCement productionFiberPolymer science

Fibers of diverse materials find widespread use in inorganic binder compositions to improve the properties of the final cured composite materials. When using high amounts of fiber in inorganic binderslurries, problems arise due to the loss of workability because of unevenly distributed fiber content. The fibers according to the invention allow the use of large amounts of fiber without loss of workability and are particularily useful to control the rheology of the composite slurry mixtures. The fibers according to the invention are bicomponent fibers comprising a first hydrophobic polymer anda second hydrophilic polymer, and are obtained by: - uniaxially stretching a sheet of a first polymer; - oxidizing one side of a sheet of said first polymer; - coating the oxidized side of a sheet ofsaid first polymer with said second polymer; - drying the resulting bicomponent substrate; - cutting the dried bicomponent substrate into fibers of desired dimensions.

Owner:CONSTR RES & TECH GMBH

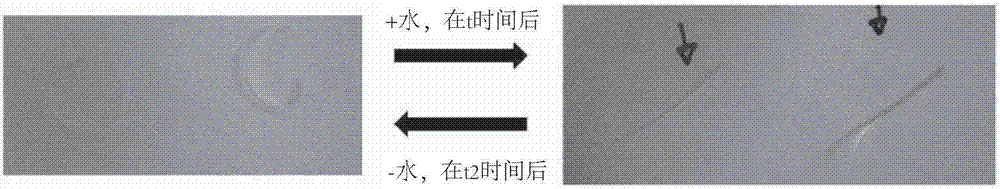

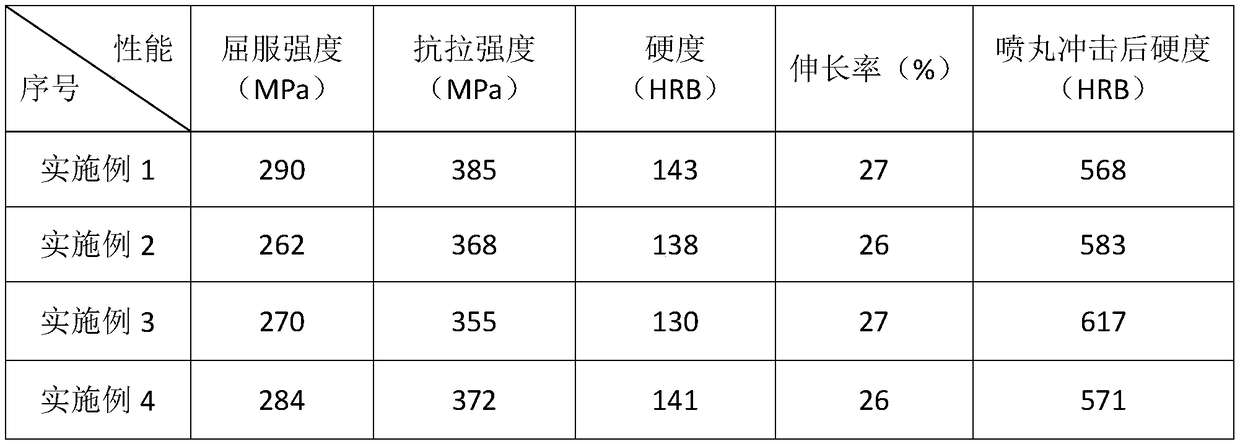

Production method for manufacturing vehicle-mounted concrete tank

ActiveCN109321832AImprove corrosion resistanceReduced machinabilityManufacturing technologyManganese

The invention provides a production method for manufacturing a vehicle-mounted concrete tank, and relates to the technical field of metallurgy manufacturing. Raw materials include, by mass percent, 0.15%-0.18% of C, 0.10%-0.20% of Si, 3.35%-4.50% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.010% of S, 0.20%-0.40% of Cu and the like. The method comprises the following machining steps including the slab heating procedure, the high-pressure descaling procedure, the controlled rolling procedure and the curling procedure. According to the provided production method for manufacturing the vehicle-mounted concrete tank, the high manganese content is adopted, so that a matrix structure of a produced steel plate contains a large amount of metastable state austenite, and the characteristics that plasticity is good, and machining forming is easy are achieved. After the surface of the steel plate is subjected to impacts, the surface austenite can be converted into a hardmartensitic structure, accordingly, very high hardness and abrasion resisting performance are achieved, the steel plate is suitable for the later usage environment in which continuous friction with concrete exists, and the service life is prolonged.

Owner:HEBEI IRON AND STEEL

Cold heading steel, ladle furnace refining process of cold heading steel and production process of cold heading steel

InactiveCN104513931BImprove machinabilityImprove cleanlinessProcess efficiency improvementElectric furnaceRoom temperatureUltimate tensile strength

The present invention provides a cold heading steel, a cold heading steel ladle furnace refining process and a cold heading steel production process. The cold heading steel comprises the following chemical components by weight: 0.19-0.22% of C, less than or equal to 0.10% of Si, 0.75-0.90% of Mn, less than or equal to 0.025% of P, less than or equal to 0.030% of S, more than or equal to 0.02% of AlT, less than or equal to 0.20% of Cr, less than or equal to 0.20% of Ni, less than or equal to 0.20% of Cu, and the balance of Fe. According to the present invention, in the cold heading steel production process, application of aluminum to carry out deep deoxidation, silicon calcium wire feeding, immersion type nozzle application and other steps are adopted, such that the internal components of the produced cold heading steel are reasonably matched, and especially the combination of the C with the content of 0.19-0.22% and the Si with the content of less than or equal to 0.10% makes the cold heading steel meet strength, toughness and other comprehensive mechanical properties, such that the workability of the cold heading steel at a room temperature is good.

Owner:NEW FOUNDER HLDG DEV LLC +2

Chromium-iron-aluminum alloy with surface rich in aluminum

The invention relates to a chromium-iron-aluminum alloy with the surface rich in aluminum. Raw materials of the iron-chromium-aluminum alloy are ingot iron, chromium metal and aluminum nitride powder.In the preparation process of the iron-chromium-aluminum alloy, after the ingot iron, the chromium metal and 1 / 3 of aluminum nitride powder are subjected to primary smelting in a medium-frequency induction furnace, slag is removed; 1 / 3 of aluminum nitride powder is secondarily added into molten steel obtained after slag removal for secondary smelting; after smelting, an iron-chromium-aluminum alloy ingot is obtained through casting; the iron-chromium-aluminum alloy ingot is buried in the remaining 1 / 3 of aluminum nitride powder to be placed into a vacuum induction furnace for ternary smelting; the temperature is controlled to range from 2,100 DEG C to 2,300 DEG C, and the smelting time is controlled to range from 30 min to 50 min; and then fast cooling is carried out till the temperatureranges from 1,000 DEG C to 1,100 DEG C, constant-temperature sintering is carried out for 30 min to 50 min at the temperature, and the iron-chromium-aluminum alloy with the surface rich in aluminum isobtained after cooling. The quick life value of a wire made of an iron-chromium-aluminum alloy material high in aluminum content ranges from 150 h to 200 h at the temperature being 1,300 DEG C, the service life is long, and application of the iron-chromium-aluminum alloy can meet the requirements of special industries.

Owner:YANCHENG XINYANG ELECTROTHERMAL MATERIAL CO LTD

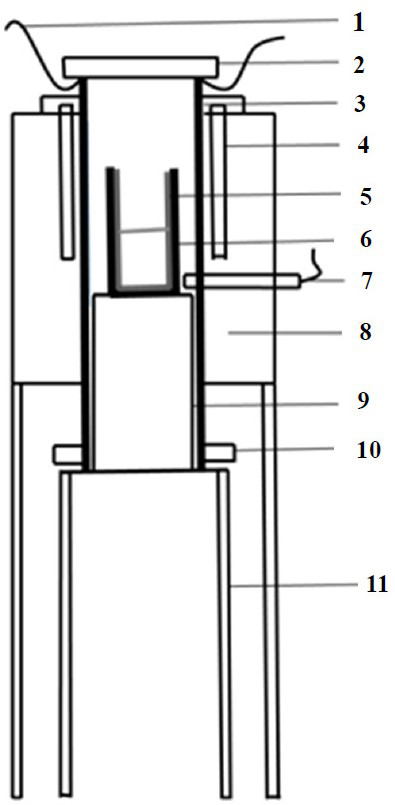

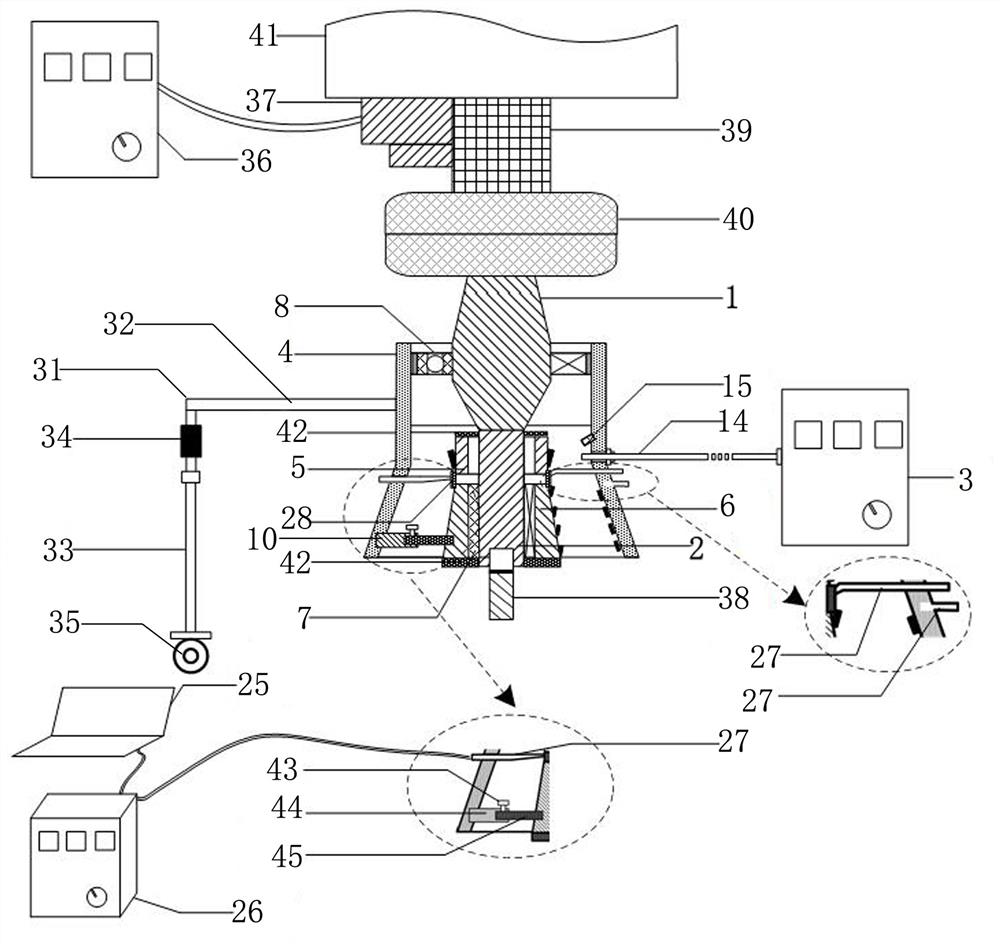

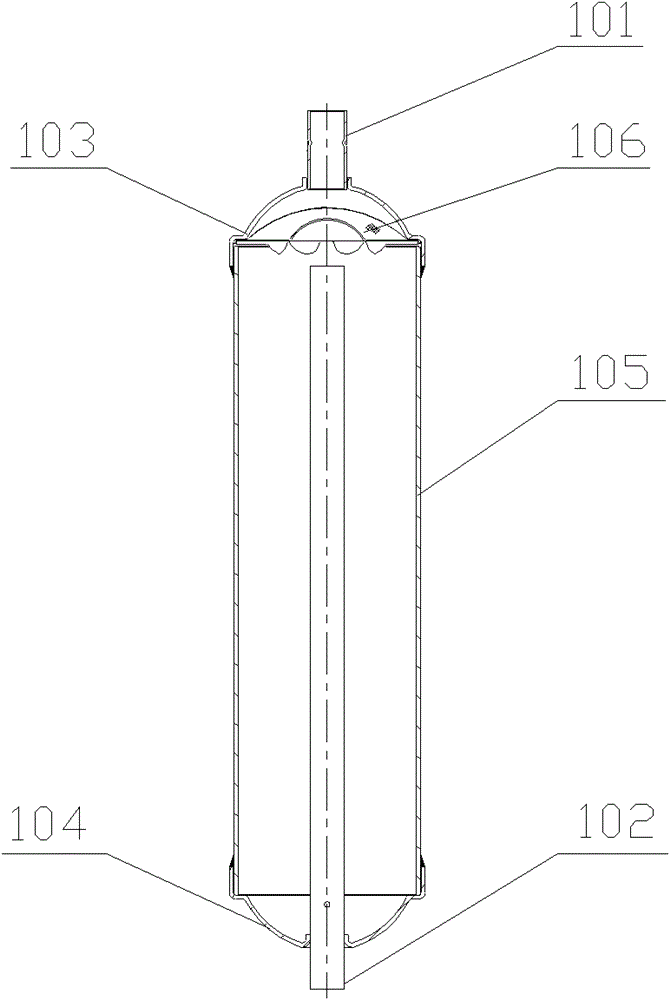

An ultrasonic-assisted laser surface modification device

ActiveCN113857653BAchieve real-time laser heatingTo achieve a compound strengthening effectLaser beam welding apparatusBeam splittingMachined surface

The technical field of laser processing equipment of the present invention is specifically an ultrasonic-assisted laser surface modification device, which solves the technical problems in the background technology. It includes an ultrasonic vibration cutting device and a laser heating device, and the ultrasonic vibration cutting device includes a coaxial connected Horn and tool seat, also includes ultrasonic generator, non-contact electrical signal transmitter, processing tool and installation handle for connecting machine tool spindle; laser heating device includes laser generator, light guide cover, upper ring light guide mirror and lower ring light guide mirror. The present invention can realize real-time laser heating of the processed surface of the workpiece during the cutting process, and improve the processing efficiency while reducing the machinability of difficult-to-machine materials; the circumferential rotation of the upper annular light guide mirror can realize the circumferential light splitting of the laser, The axial reciprocating vibration of the lower annular light guide mirror can realize the axial splitting of the laser light, thereby realizing the control of the laser heating trajectory, and effectively reducing the occurrence of local overheating of the workpiece to be processed.

Owner:山西诚鹏润德科技股份有限公司

Gas-liquid separator

ActiveCN103245143BEfficient separationAvoid shockReversed direction vortexSuction cleanersVapor–liquid separatorEngineering

The invention discloses a gas-liquid separator, which is used in a refrigeration system, comprising a cylinder body, an inlet pipe fixedly connected to the upper end of the cylinder body, an outlet pipe fixedly connected to the lower end of the cylinder body, and an air guide element, The air guiding element further includes a baffle, a flange at one end of the baffle and a bottom plate at the other end of the baffle; the baffle is located above the outlet pipe and blocks the air inlet of the outlet pipe; the The flange is fixedly connected to the inner wall of the cylinder; the bottom plate is fixedly connected to the side wall of the inlet end of the outlet pipe. The air guiding element provided by the invention is processed by steel plate with simple processing technology, which can not only effectively prevent liquid from entering the outlet pipe and avoid liquid shock to the compressor, but also can replace the positioning device to fix the outlet pipe.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

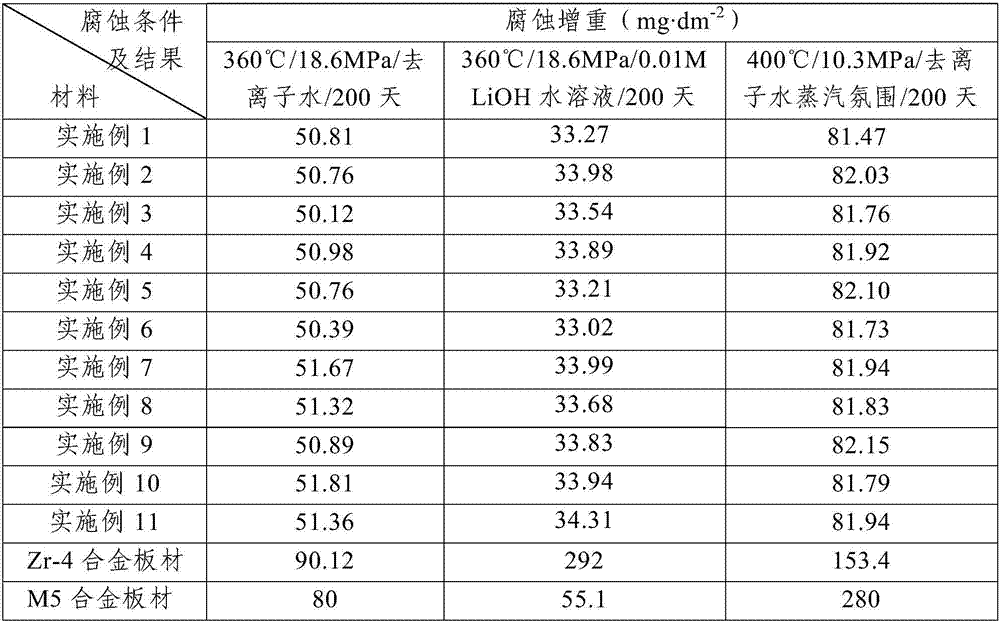

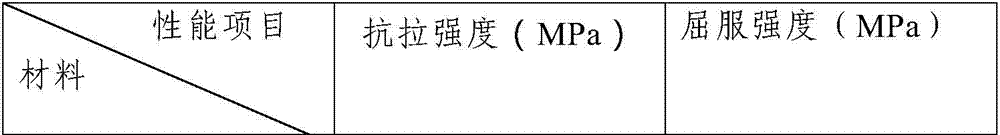

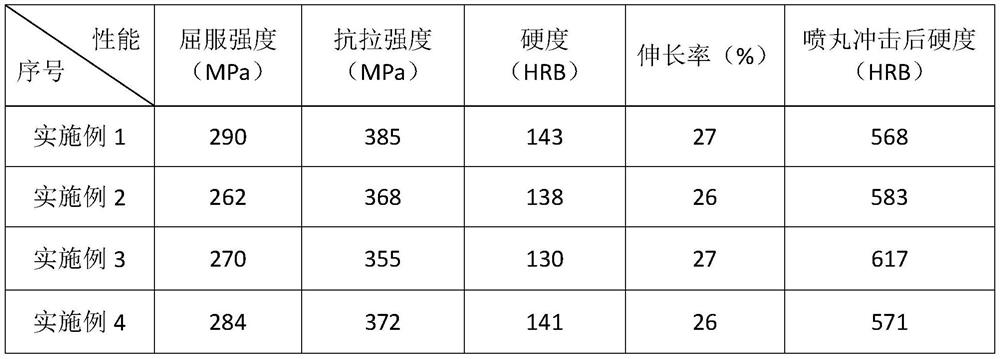

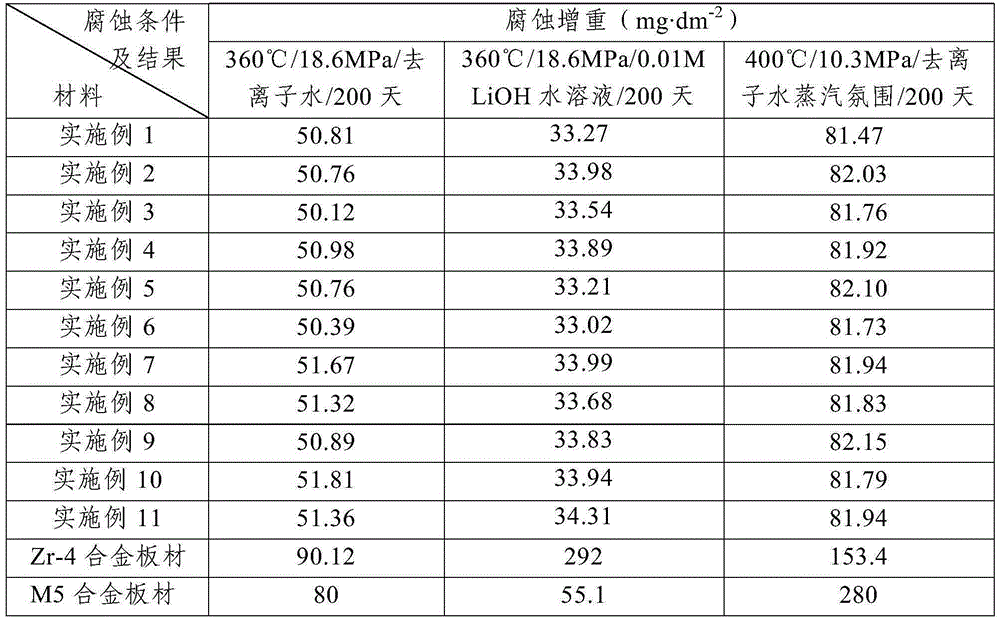

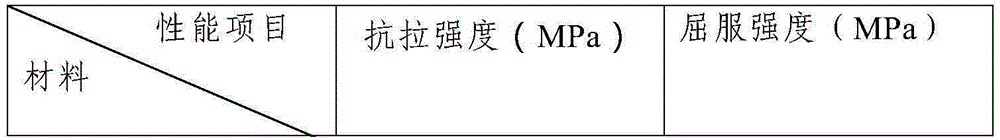

Corrosion-resistant zirconium-tin-niobium alloy for nuclear reactor core and preparation method thereof

The invention discloses a corrosion-resistant zirconium-tin-niobium alloy for nuclear reactor core, which is composed of the following components in mass percentage: Sn 0.6%-1.5%, Nb 0.1%-0.5%, Fe 0.1%-0.6%, Cr 0.1% ~0.5%, Cu 0.01%~0.3%, Mg 0.005%~0.2%, O 600ppm~1400ppm, the balance is Zr and unavoidable impurities. In addition, the present invention also discloses a method for preparing the zirconium-tin-niobium alloy, the method is: 1. preparing a Zr-Cu-Mg master alloy; 2. preparing a Zr-Nb master alloy; 3. preparing a Zr-Sn-Fe-Cr Master alloy; 4. Preparation of zirconium-tin-niobium alloy. The zirconium-tin-niobium alloy of the invention has excellent corrosion resistance and mechanical properties, and is suitable for cladding materials, grids and other structural components of nuclear reactor fuel rods in nuclear power plants.

Owner:西安西部新锆科技股份有限公司

Production method for making vehicle-mounted concrete tank

The invention provides a production method for manufacturing a vehicle-mounted concrete tank, and relates to the technical field of metallurgy manufacturing. Raw materials include, by mass percent, 0.15%-0.18% of C, 0.10%-0.20% of Si, 3.35%-4.50% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.010% of S, 0.20%-0.40% of Cu and the like. The method comprises the following machining steps including the slab heating procedure, the high-pressure descaling procedure, the controlled rolling procedure and the curling procedure. According to the provided production method for manufacturing the vehicle-mounted concrete tank, the high manganese content is adopted, so that a matrix structure of a produced steel plate contains a large amount of metastable state austenite, and the characteristics that plasticity is good, and machining forming is easy are achieved. After the surface of the steel plate is subjected to impacts, the surface austenite can be converted into a hardmartensitic structure, accordingly, very high hardness and abrasion resisting performance are achieved, the steel plate is suitable for the later usage environment in which continuous friction with concrete exists, and the service life is prolonged.

Owner:HEBEI IRON AND STEEL

Corrosion-resistant zirconium-tin-niobium alloy for nuclear reactor core and preparing method of corrosion-resistant zirconium-tin-niobium alloy

The invention discloses corrosion-resistant zirconium-tin-niobium alloy for a nuclear reactor core. The corrosion-resistant zirconium-tin-niobium alloy for the nuclear reactor core is prepared from, by mass, 0.6%-1.5% of Sn, 0.1%-0.5% of Nb, 0.1%-0.6% of Fe, 0.1%-0.5% of Cr, 0.01%-0.3% of Cu, 0.005%-0.2% of Mg, 600 ppm-1400 ppm of O and the balance Zr and inevitable impurities. In addition, the invention discloses a preparation method of the zirconium-tin-niobium alloy. The preparation method comprises the steps that firstly, Zr-Cu-Mg intermediate alloy is prepared; secondly, Zr-Nb intermediate alloy is prepared; thirdly, Zr-Sn-Fe-Cr intermediate alloy is prepared; and fourthly, the zirconium-tin-niobium alloy is prepared. The zirconium-tin-niobium alloy has excellent corrosion resistance and mechanical performance and is suitable for severing as a cladding material, a grating and other structural components of nuclear reactor fuel rods of nuclear power plants.

Owner:西安西部新锆科技股份有限公司

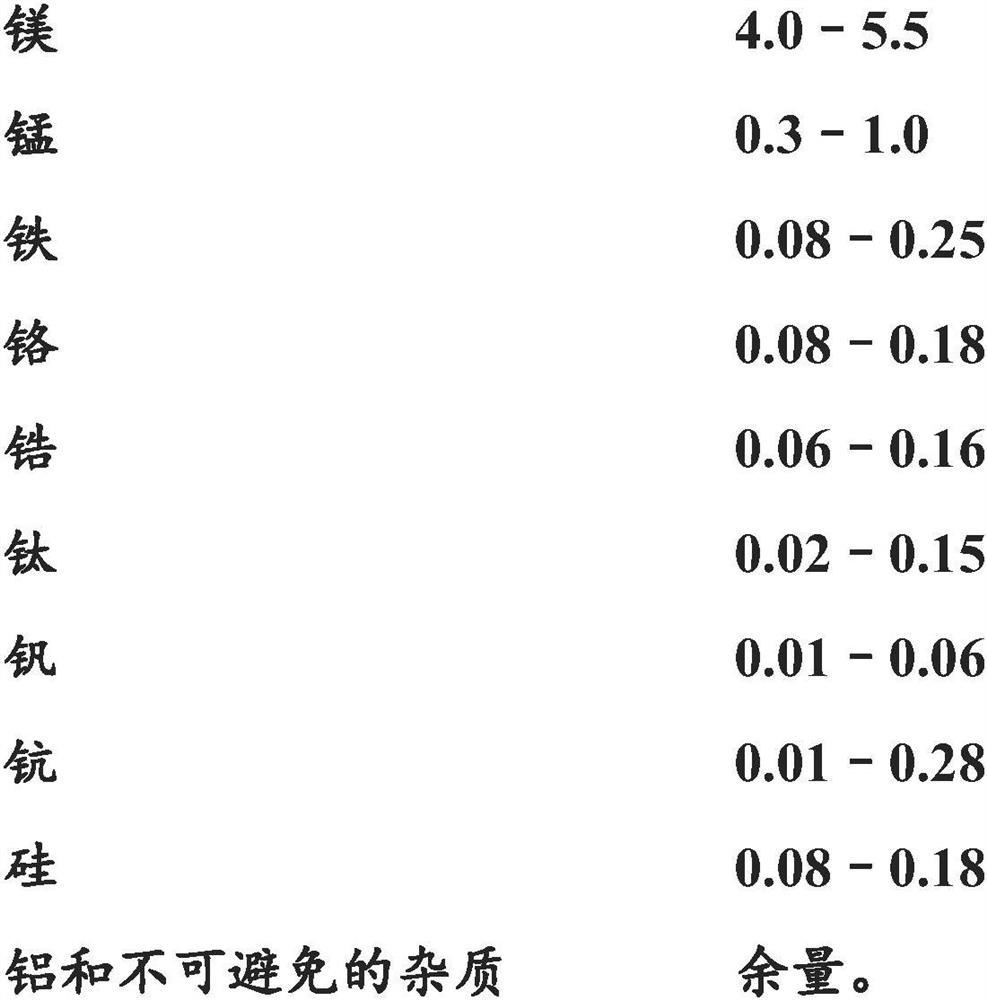

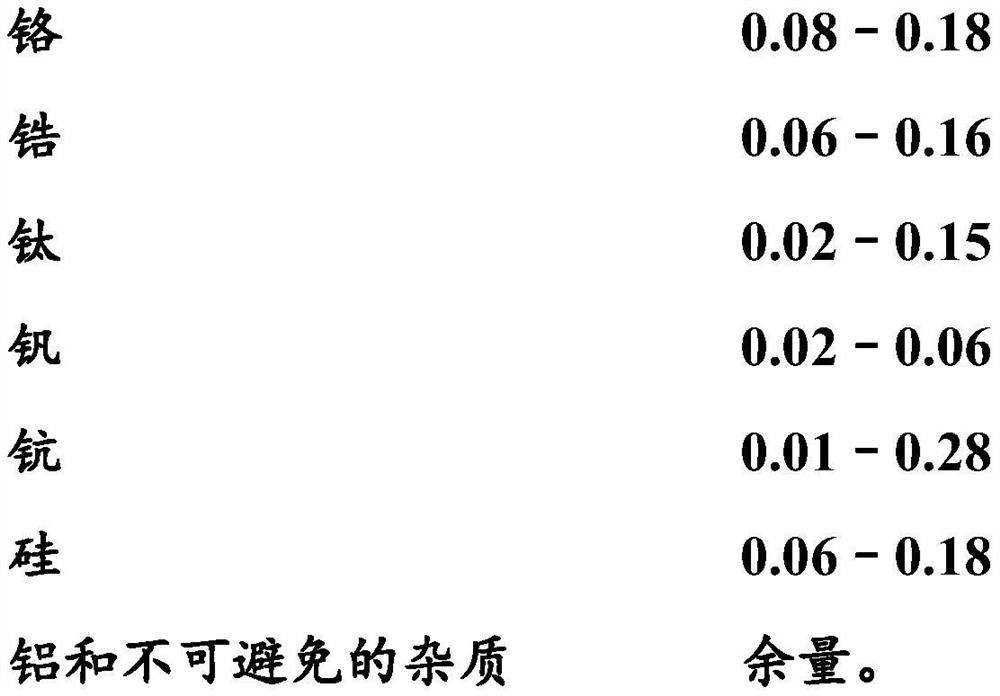

Aluminum-based alloy

The invention relates to the field of the metallurgy of aluminium-based materials and can be used in the manufacture of articles for work in corrosive environments under the weight of heavy loads, including in elevated and cryogenic temperatures. Proposed is a new aluminium alloy having a structure consisting of an aluminium solution, secondary separations and a eutectic phase, formed by elements such as magnesium, manganese, iron, chromium, zirconium, titanium and vanadium. The alloy additionally contains silicon and scandium, an at least 75% share of each element from the group consisting of zirconium and scandium forming the secondary separations with an L12-type lattice in an amount of at least 0.18 vol.% and a particle size of no more than 20 nm, for a given alloying element redistribution.

Owner:OBSHCHESTVO S OGRANICHENNOY OTVETSTVENNOSTYU OBEDINENNAYA KOMPANIYA RUSAL INZHENERNO TEKHNOLOGICHESKIY TSENTR

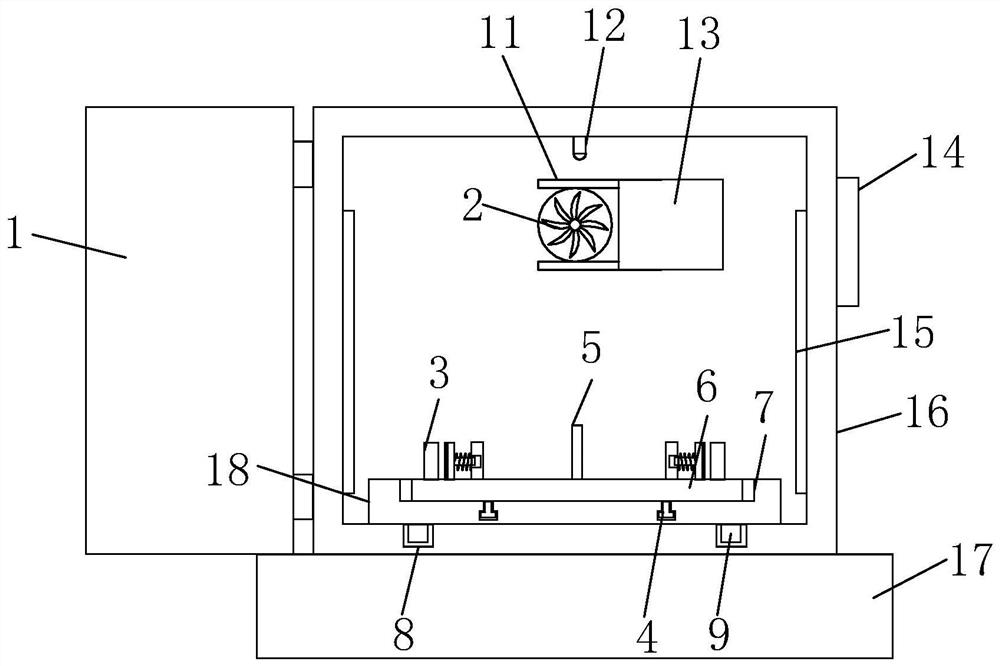

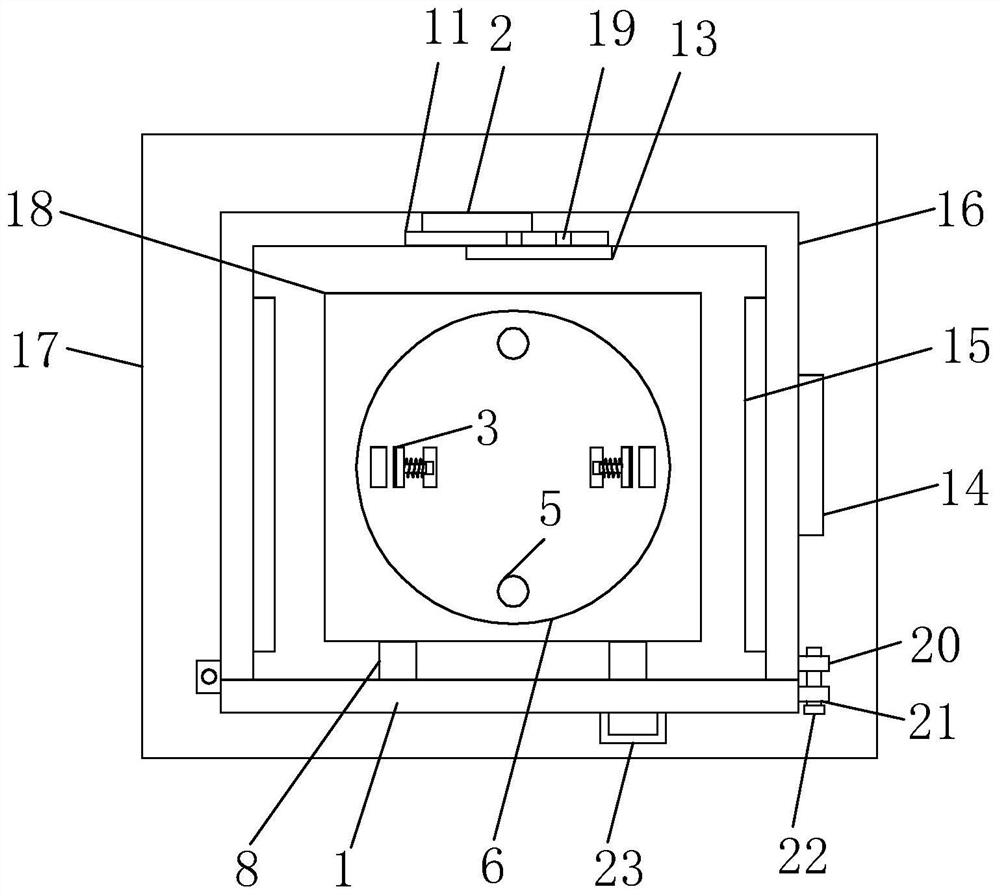

An annealing device and annealing method

ActiveCN109355477BSimple structureEasy to operateFurnace typesHeat treatment process controlMechanical engineeringMachinability

The invention relates to the technical field of material annealing, in particular to an annealing device. The annealing device comprises a box body, wherein a box door is hinged to one side of the boxbody, a handle is arranged outside the box door, a base is welded at the bottom of the box body, a control cabinet is fixedly installed on one side of the outer portion of the box body, a temperaturedetector is arranged in the middle of the upper end of the inner side of the box body, heating plates are fixedly arranged on two sides of the interior of the box body, a fixing mechanism is arrangedbetween the box body and the box door, two groups of sliding mechanisms are arranged at the lower end of the inner side of the box body, circular grooves are formed in the middle of the upper end ofa supporting plate, two groups of rotating mechanisms are arranged at the bottoms of the inner sides of the circular grooves, two groups of clamping mechanisms are arranged on the outer side of the upper end of a round plate, and a heat dissipation mechanism is further arranged at the upper end of one side of the box body. The annealing device is stable in structure, convenient to operate and capable of effectively reducing the hardness, and improves the cutting machinability, eliminates the residual stress, stabilizes the size, and reduces the deformation and the crack tendency.

Owner:浙江星一康铜业有限公司

Holemaking tool with independent drill point in the center

ActiveCN109732127BImprove stabilityGuaranteed dimensional accuracyTransportation and packagingTrepanning drillsEngineeringDrill

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

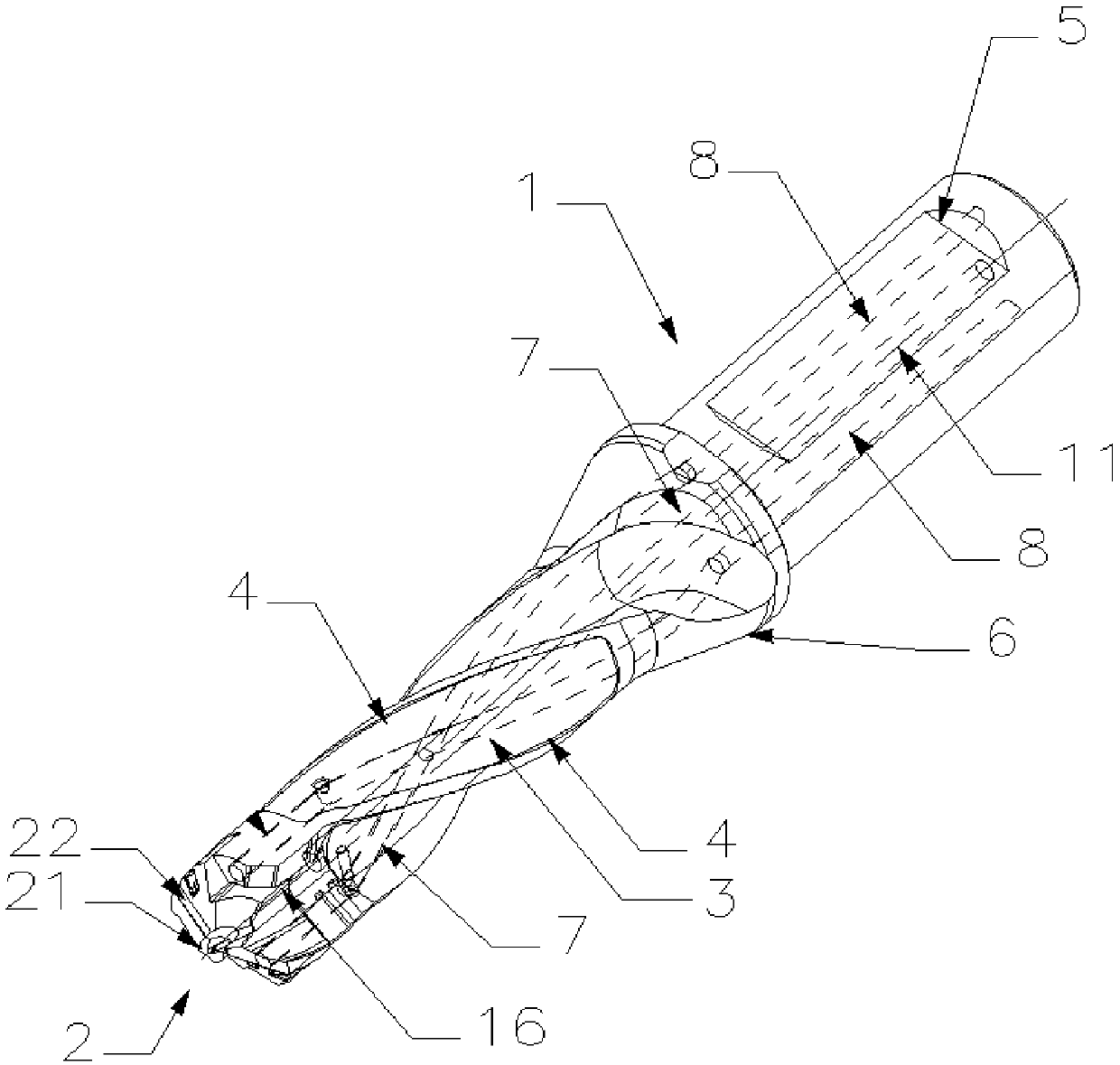

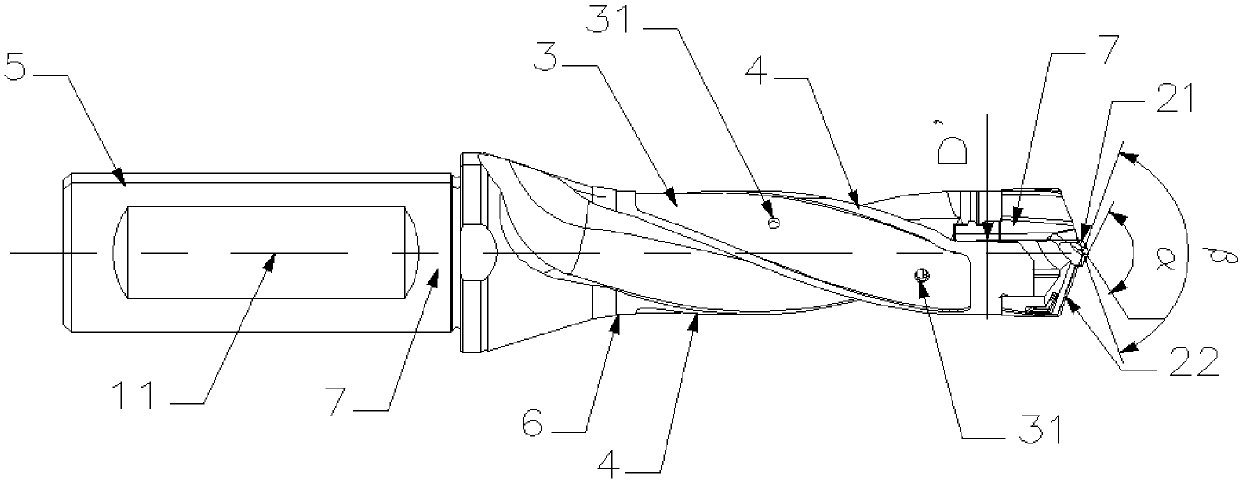

dental root canal

ActiveCN113197685BReliable followPrevent in-depthTeeth fillingTeeth cappingEngineeringBiomedical engineering

Owner:MATSUTANI SEISAKUSHO CO LTD

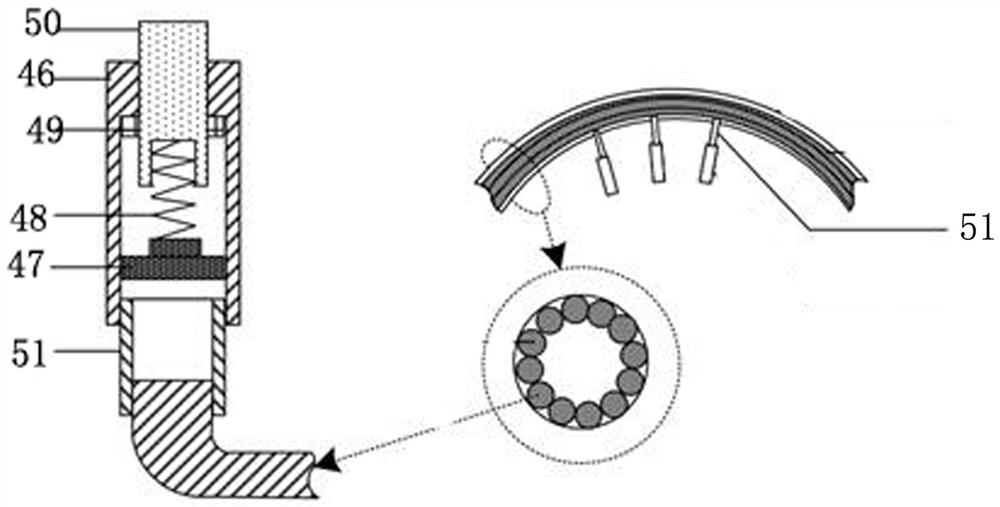

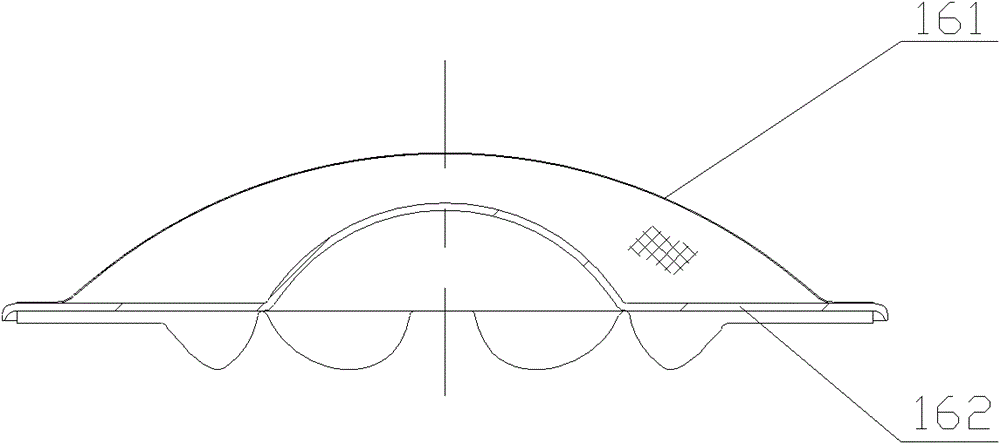

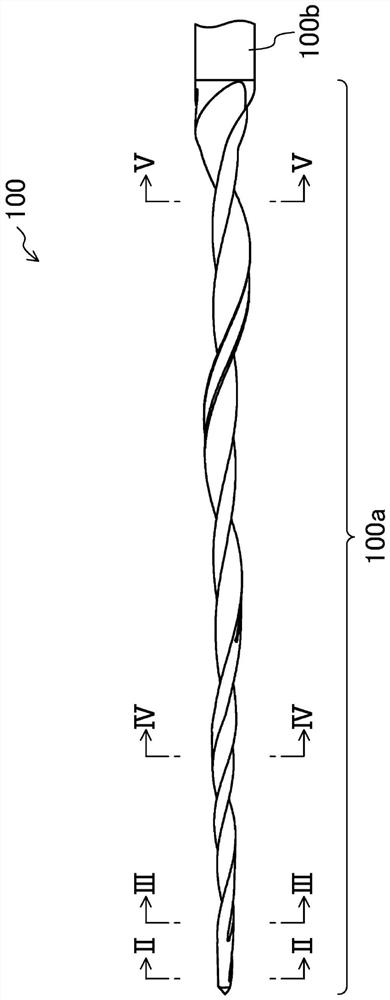

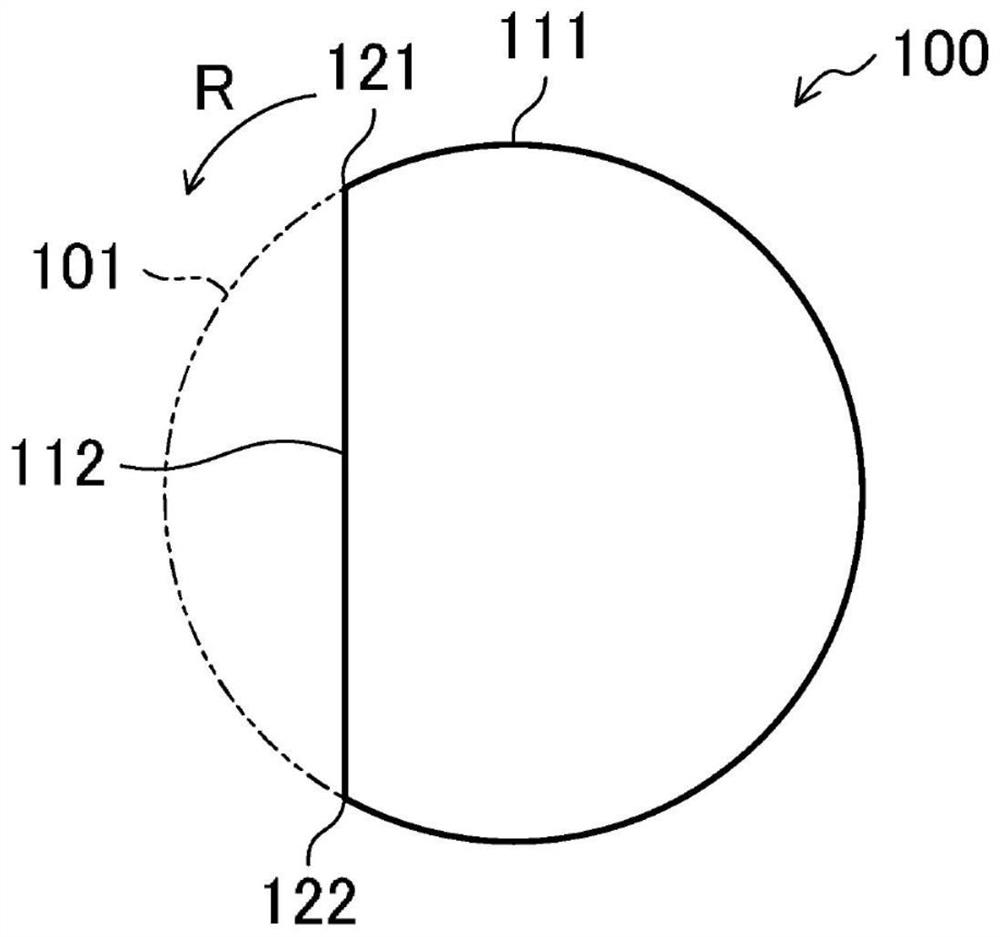

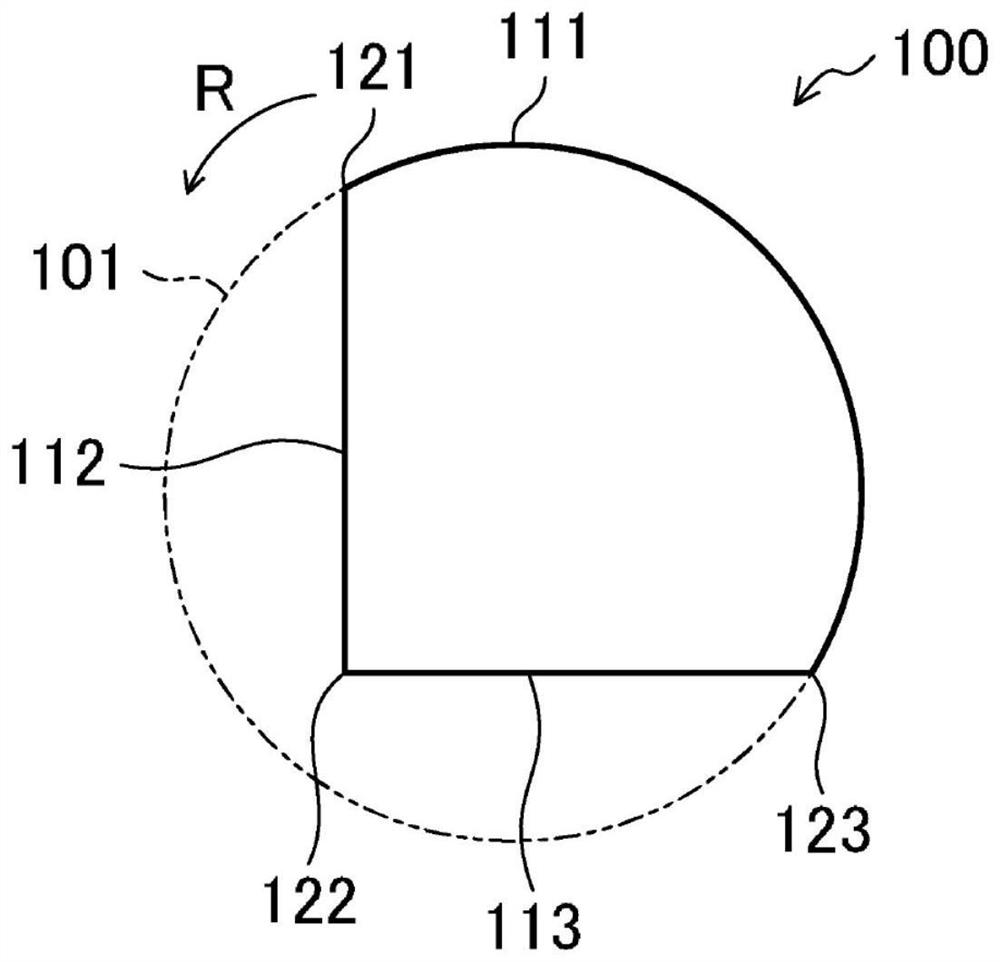

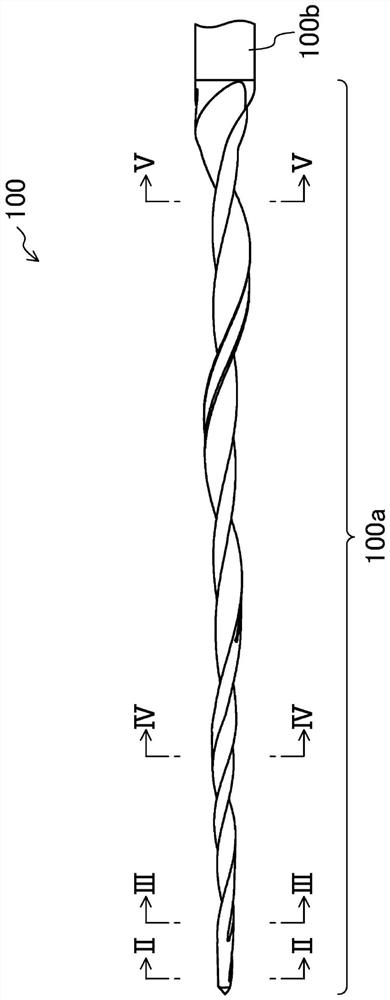

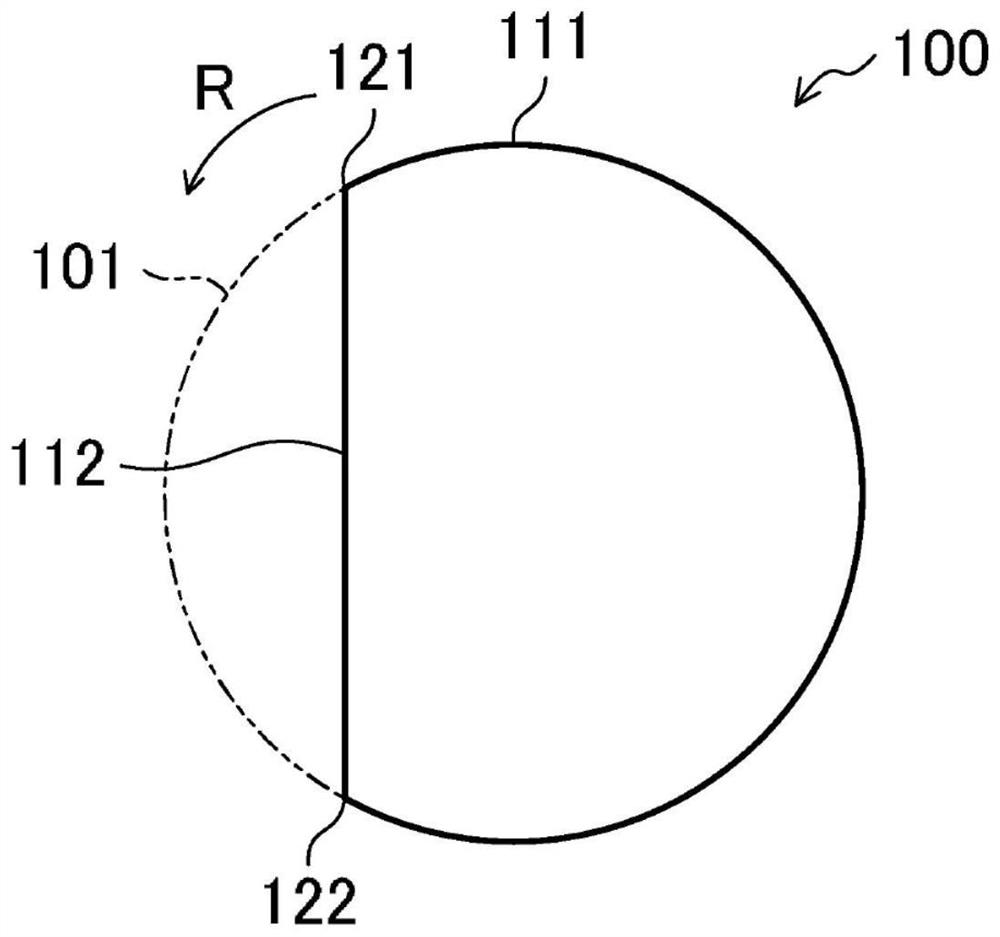

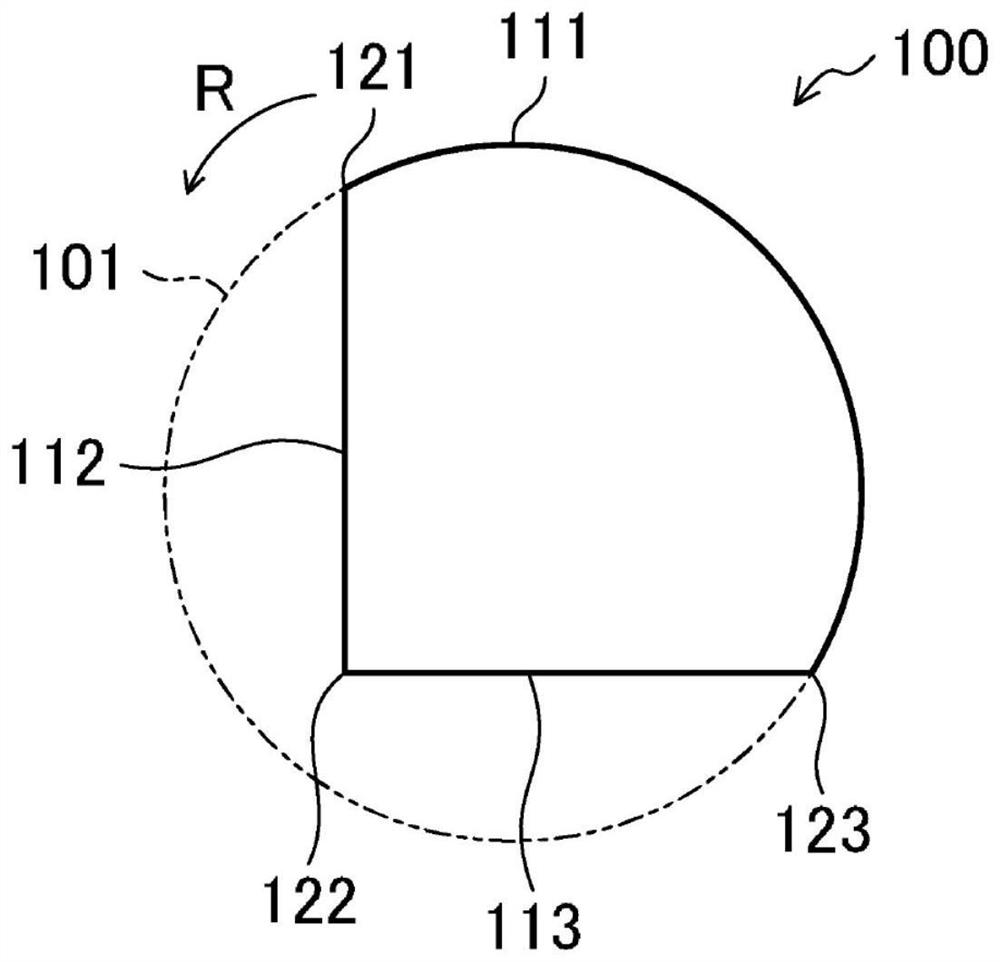

Dental root canal treatment instrument

ActiveCN113197685AReliable followPrevent in-depthTeeth fillingTeeth cappingBiomedical engineeringRoot canal

The invention provides a dental root canal treatment instrument, which can improve the flexibility, the machinability and / or the fracture resistance of the dental root canal treatment instrument. In a dental root canal treatment instrument (100), the cross-sectional shape at a first longitudinal direction position on the tip side is configured from an arcuate part (111) and first linear parts (112), and the number of linear parts constituting the cross-sectional shape closer to the base end side than the tip side is formed so as to increase.

Owner:MANI INC

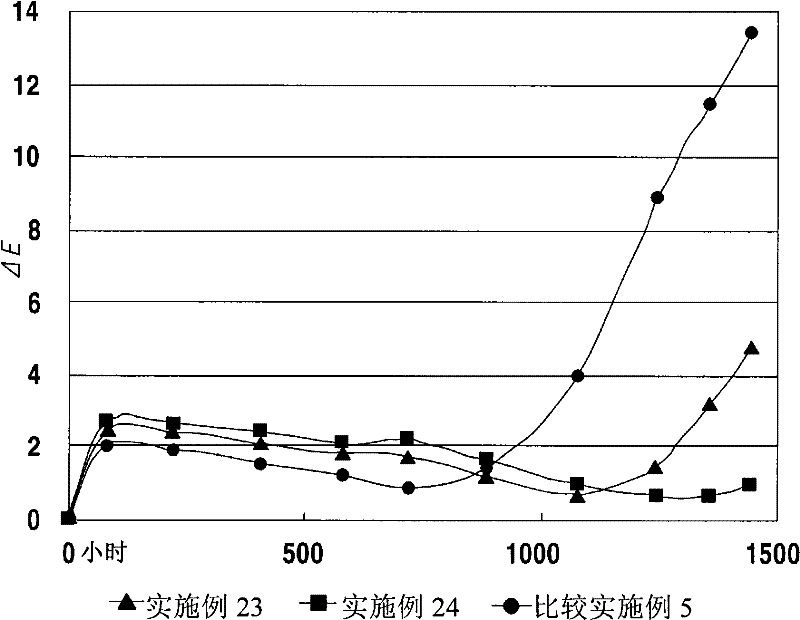

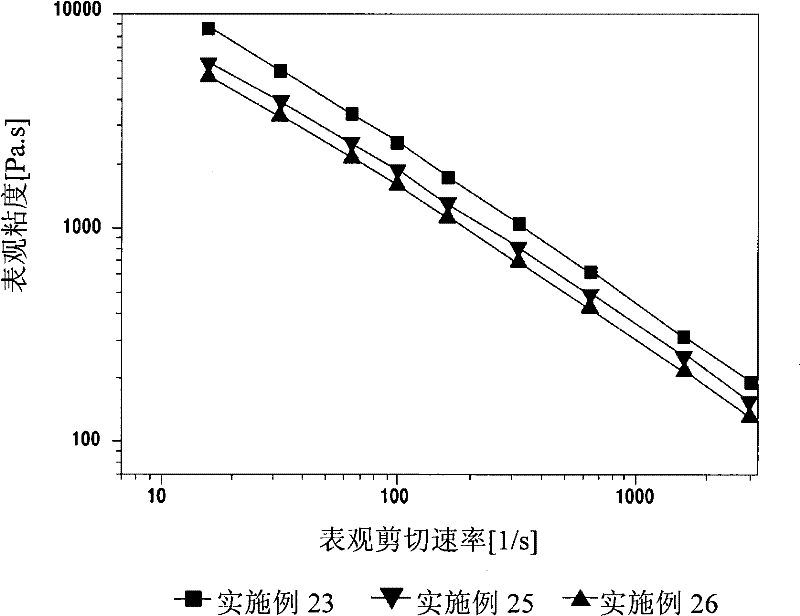

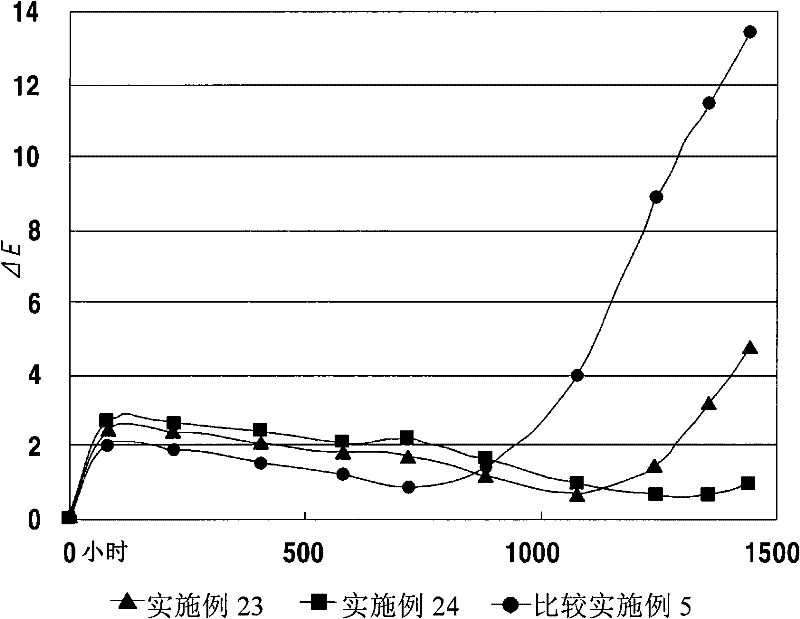

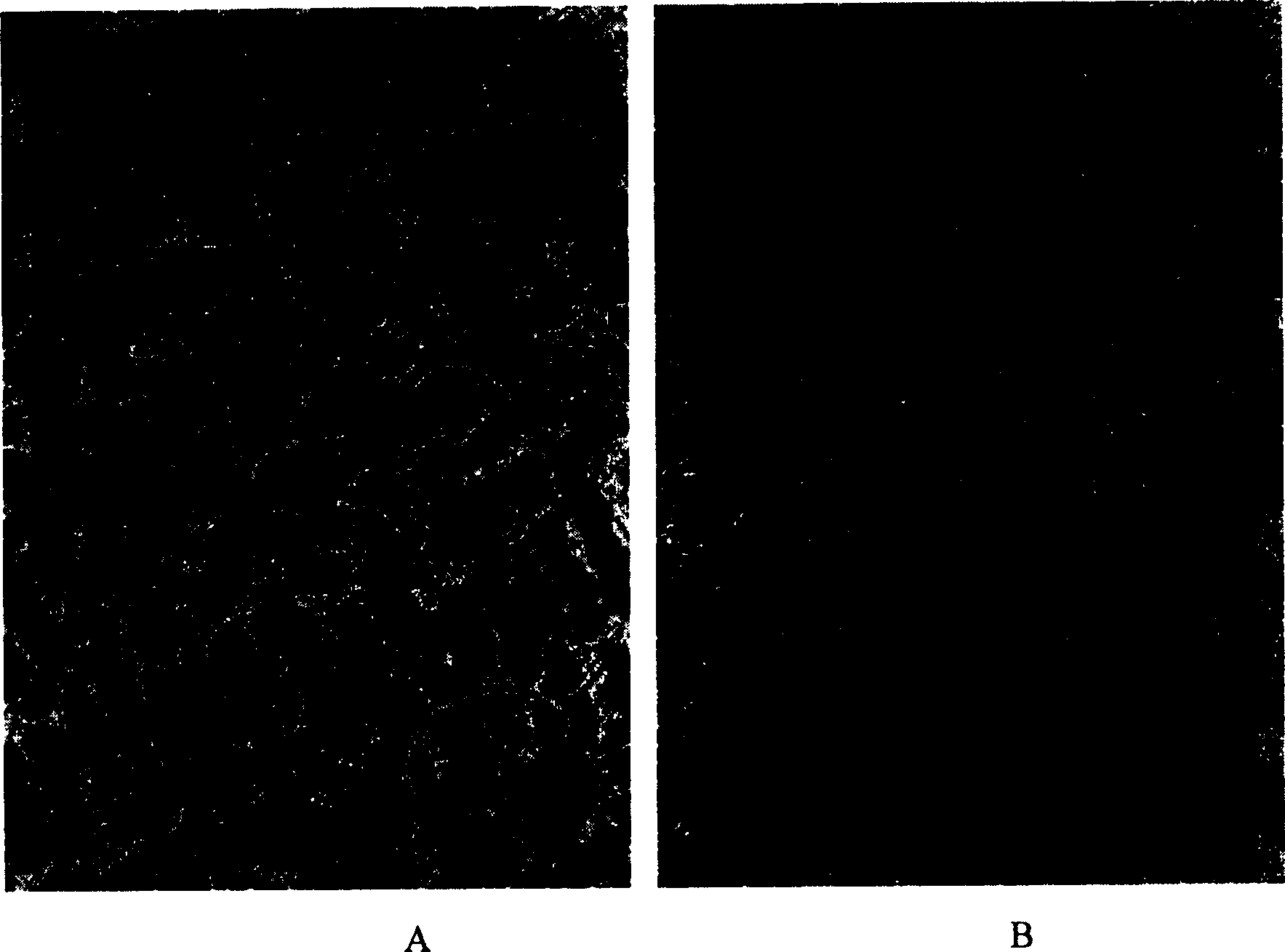

Low surface gloss styrene resin composition, low surface gloss sheet containing the same and preparing method thereof

The present invention relates to a low surface gloss styrene resin composition. The composition of the present invention is composed of (A) 80-99.9 weight% of the basic resin comprising rubber-modified styrene resin and (B) 0.1-20 weight% of syndiotactic polystyrene, the matting agent. The composition also includes (C) hydrogenated styrene block copolymer comprising styrene block and butadiene rubber block as a compatibilizer by 0.1-20 weight% for the total weight of the low surface gloss styrene resin composed of (A) the basic resin and (B) the matting agent and additionally includes (D) a plasticizer by 0.1-30 weight%. The composition of the present invention has excellent weatherability and impact-resistance in addition to the low surface gloss properties, so that it can be applied in various products, particularly exterior products for structures such as sidings and window frames, etc.

Owner:LG CHEM LTD

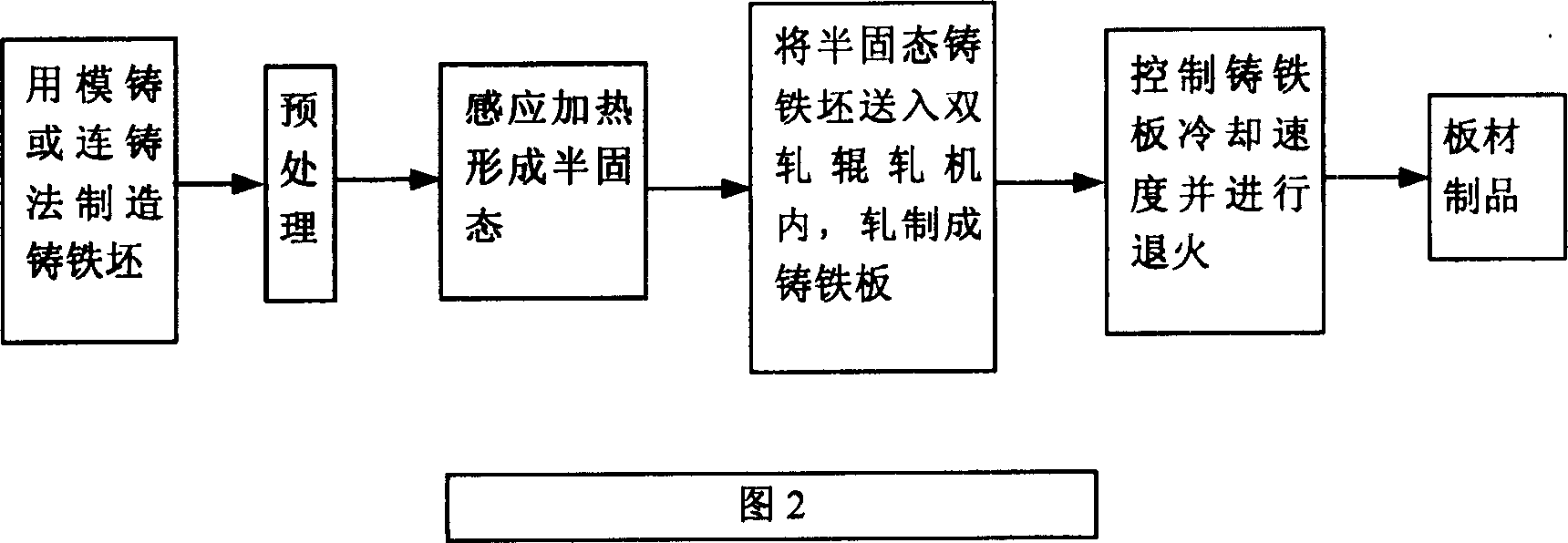

Semi-solid-state milling technology of cast iron plate material

InactiveCN1295036CRealize industrial mass productionLow powerMetal rolling arrangementsChemical compositionSemi solid

A semi-solid rolling technology for cast iron plate includes such steps as pretreating the cast iron plate, induction heating to become semi-solid, dual-roller rolling, proper cooling, and annealing. The thickness of cast iron plate can be regulated within 0.5 mm-50mm, the strength of extension is more than 400 MPa and the enlongation is greater than 5%.

Owner:NANJING NANGANG IND DEV CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com