Composite fiber for inorganic binder applications

A fiber and two-component fiber technology, applied in the field of composite fibers for inorganic binder applications, can solve the problems of reduced fluidity and operability of mixtures, affecting rheological properties of inorganic binder mixtures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

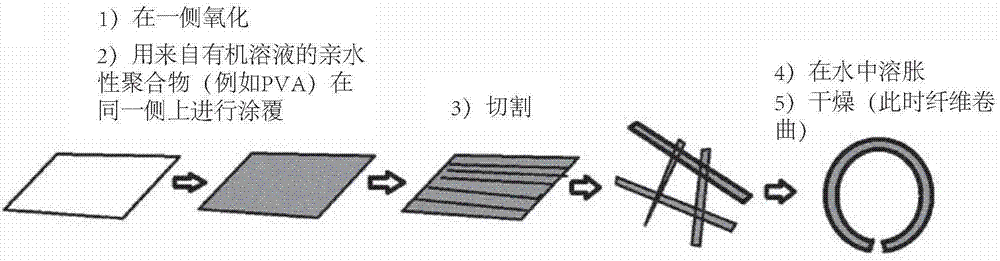

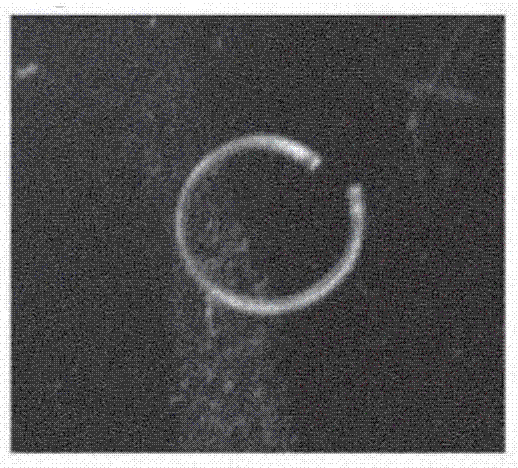

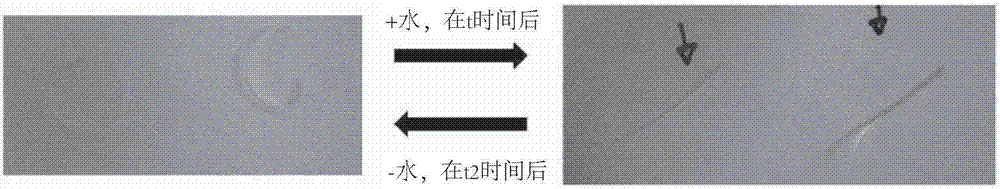

[0049] A 40 micron thick PP sheet oxidized with a 5% potassium persulfate solution for 6 hours at 60°C was coated with a saturated aqueous solution of polyvinyl alcohol (eg Mowiol 4-88; Kuraray Ltd.) and dried at 70°C . After this step, the sheet is cut longitudinally into crimped or instant crimped fibers ( figure 2 ). After being placed in water for 30min-60min, the resulting annular fiber element is stretched or stretched ( image 3 ). When the amount of hydrophilic polymer solution was doubled, the thickness of the resulting layer on PP doubled, which resulted in a stronger curling effect and took longer (over 60 minutes) to stretch when placed in water.

Embodiment 2

[0051] A 100 micron thick PP sheet oxidized with a 5% potassium persulfate solution for 6 hours at 60°C was coated with a saturated aqueous solution of polyvinyl alcohol (e.g. Mowiol 4-88; Kuraray Ltd.) plus 10% barium sulfate powder. Cover and dry at 70 °C. After this step, the sheet is cut longitudinally into fibers that are immediately crimped. When these coiled, looped fibers are placed in water, they stretch, or stretch.

Embodiment 3

[0053] A 40 micron thick PP foil oxidized with a 5% potassium persulfate solution for 6 hours at 60°C is coated with a saturated aqueous solution of polyacrylic acid (eg Sokalan PA 40 or Sokalan CP 12S; BASF SE) and dried at 70°C . After this step, the sheet is cut longitudinally into fibers that are immediately crimped. When these looped fibers are placed in water, they stretch, or stretch, as described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com