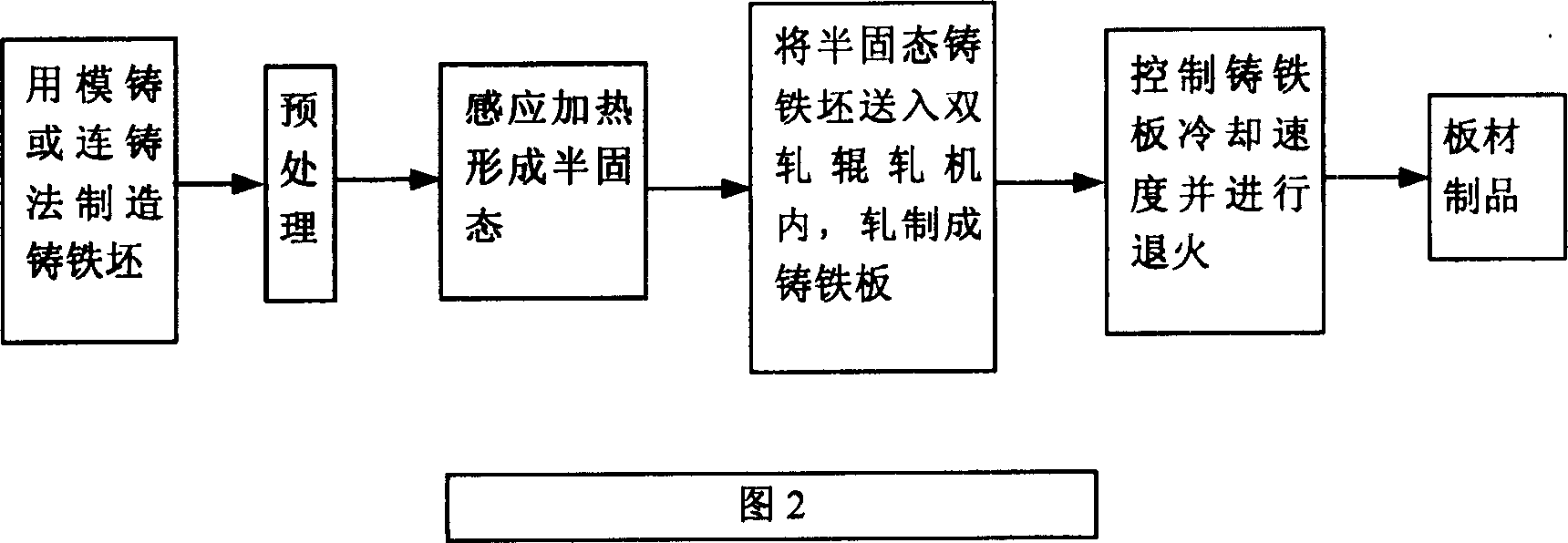

Semi-solid-state milling technology of cast iron plate material

A semi-solid, cast iron technology, used in metal rolling and other directions, can solve the problems of semi-solid continuous casting process design and control theory that have not been formed, cannot be solved, and cannot be lubricated by slag, and achieve low mechanical properties and production efficiency. The effect of low power and excellent cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: manufacture gained cast iron billet with mold casting or continuous casting method, the cross-sectional shape of cast iron billet is the square of 50mm * 50mm, length is 800mm, and chemical composition (mass percentage) is 2.1%C, 1.4%Si, 0.6% Mn, 0.1% P, 0.1% S, the semi-solid rolling process steps of rolling it into a 10mm thick cast iron plate are: ① die casting method to prepare a square cast iron billet with a cross-sectional size of 50 mm × 50 mm; ② preheat the billet to 1080°C for 2 hours and then cooled to room temperature; ③Reheat the billet to 1180°C for 60s and then enter the double-roller rolling mill for rolling. The deformation rate of the billet is 1s -1 ;④The rolled cast iron plate is properly water-cooled to 760-850°C, and then enters the follow-up annealing furnace for annealing treatment. The temperature in the annealing furnace is 780°C, and the annealing time is 10 minutes, and then slowly cooled to below 660°C and air-cooled After reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com