An annealing device and annealing method

An annealing device and annealing technology, which are applied in the direction of heat treatment process control, furnace, furnace type, etc., can solve the problems that the physical properties of materials cannot meet the expected requirements, the annealing device is large in size, and cannot be clamped by steel sheets, etc., so as to eliminate tissue defects , simple structure, the effect of eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

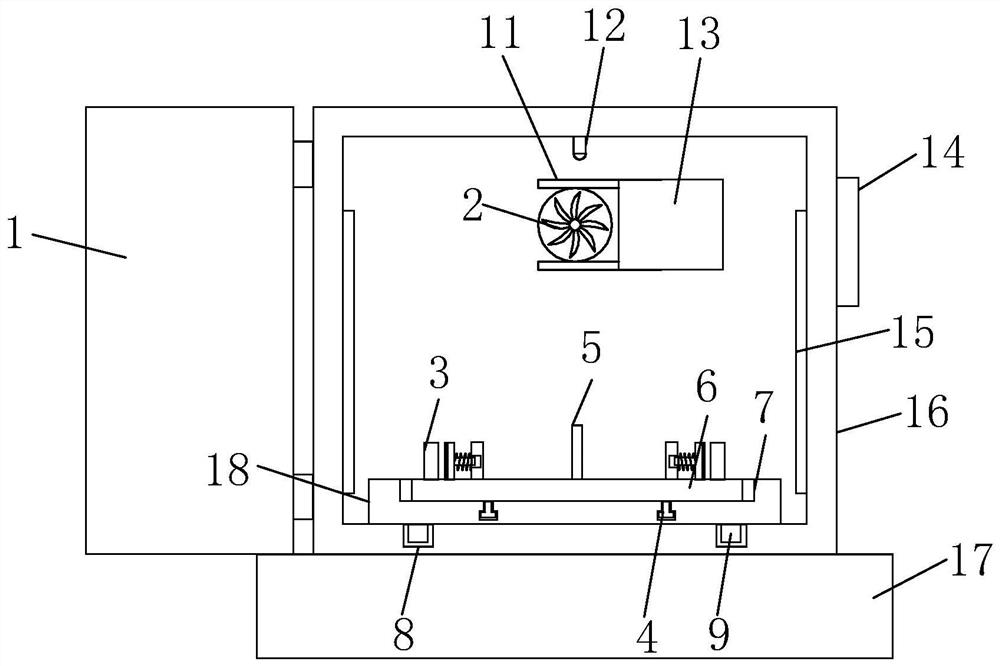

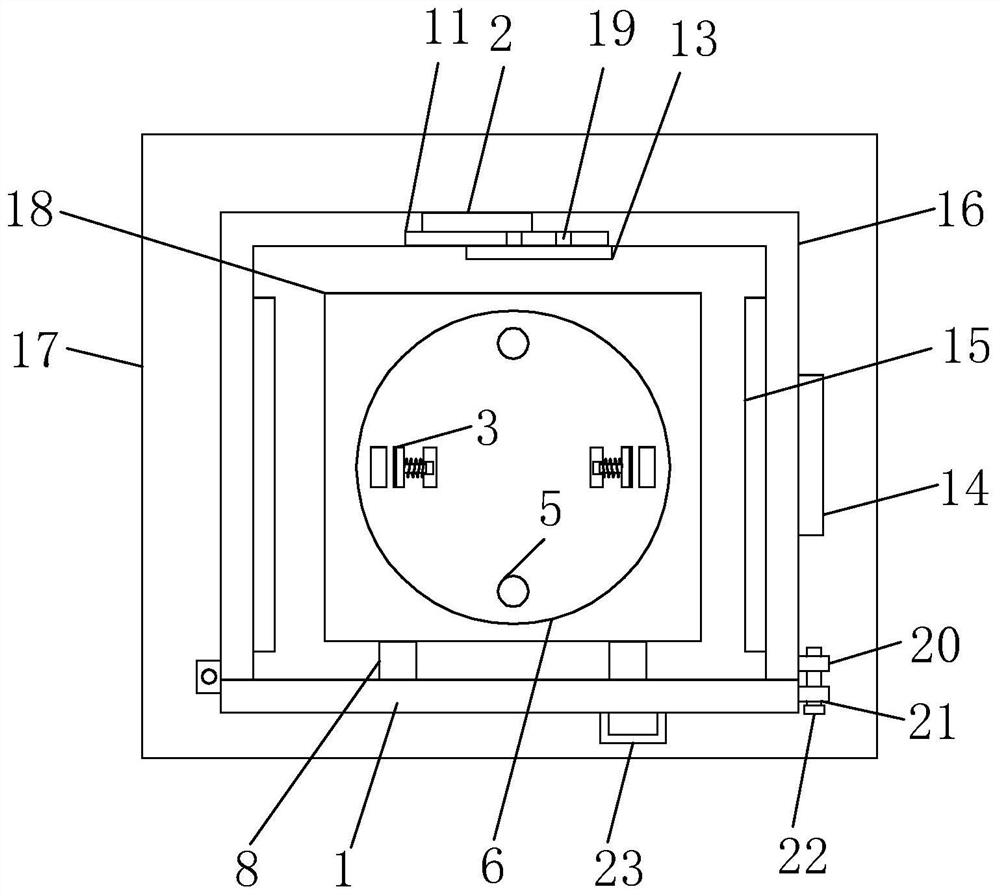

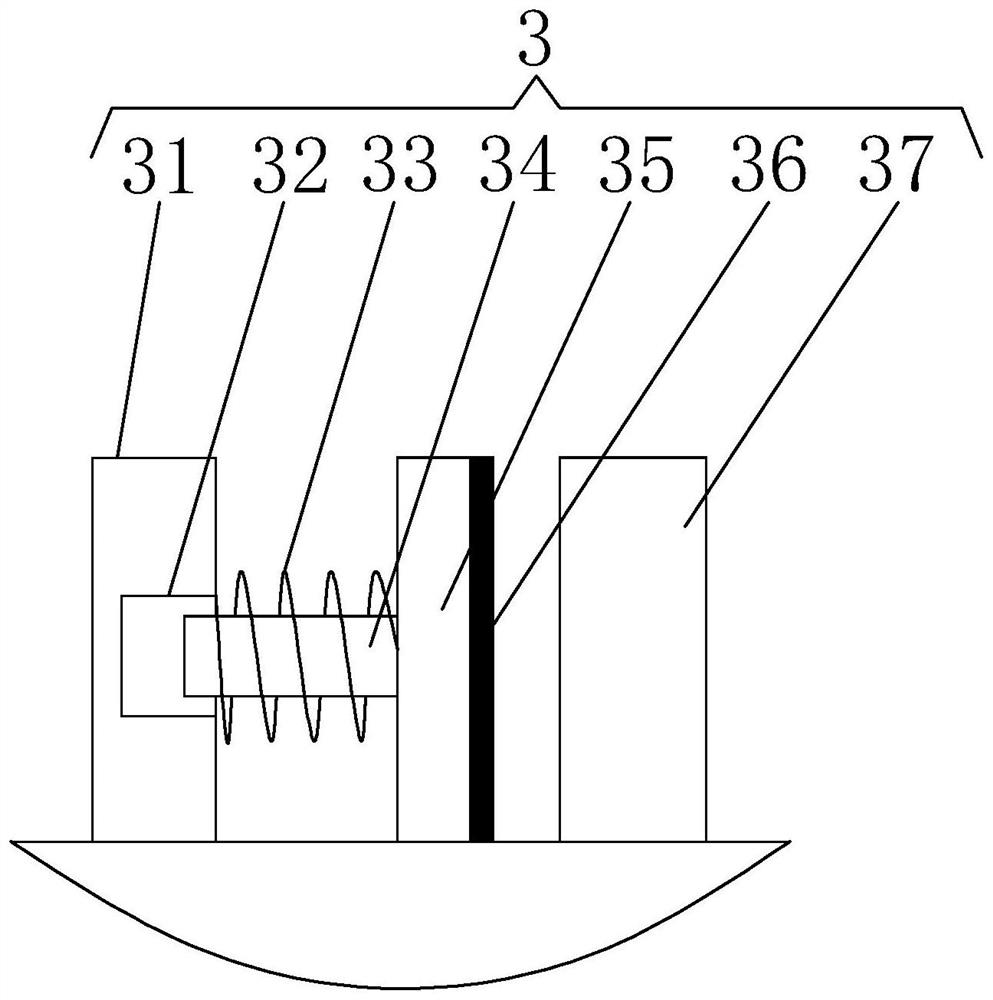

Embodiment 1

[0035] The present invention also provides an annealing method, comprising the steps of:

[0036] S1. After clamping the material to be processed in the device, heat the inside of the box 16 through the heating plate 15, heat it to 550°C at a speed of 100°C / h, and keep it warm for 2 hours;

[0037] S2. After S1 is completed, stop the continuous heating of the heating plate 15, so that the raw materials are naturally cooled to 450°C along with the box body 16;

[0038] S3. After completing S2, open the slide plate 13, open the radiator 2, and allow the raw material to fully contact with the air for cooling, so that the temperature is cooled to 180°C;

[0039] S4. After completing S3, turn off the radiator 2, turn on the heating plate 15, and continue heating. After heating the raw material to 220° C., keep it warm for 1 hour, and cool it to room temperature in the air.

Embodiment 2

[0041] S1. After clamping the material to be processed in the device, heat the inside of the box 16 through the heating plate 15, and heat it to 600°C at a speed of 110°C / h, then keep it warm for 3h;

[0042] S2. After S1 is completed, stop the continuous heating of the heating plate 15, so that the raw materials are naturally cooled to 475°C along with the box body 16;

[0043] S3. After completing S2, open the slide plate 13, open the radiator 2, and allow the raw materials to fully contact with the air for cooling, so that the temperature is cooled to 195°C;

[0044] S4. After completing S3, turn off the radiator 2, turn on the heating plate 15, and continue heating. After heating the raw material to 230° C., keep it warm for 2 hours, and then cool it to room temperature in the air.

Embodiment 3

[0046] S1. After clamping the material to be processed in the device, heat the inside of the box 16 through the heating plate 15, and heat it to 650°C at a speed of 120°C / h, and then keep it warm for 4 hours;

[0047] S2. After S1 is completed, stop the continuous heating of the heating plate 15, so that the raw materials are naturally cooled to 500°C along with the box body 16;

[0048] S3, after completing S2, open the slide plate 13, open the radiator 2, let the raw material fully contact with the air for cooling, so that the temperature is cooled to 210°C;

[0049] S4. After completing S3, turn off the radiator 2, turn on the heating plate 15, and continue heating. After heating the raw material to 240° C., keep it warm for 3 hours, and then cool it to room temperature in the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com