A kind of cutting tool with superhard film coating and its preparation method

A hard coating and cutting tool technology, applied in coating, chemical instruments and methods, metal material coating technology, etc., can solve the problems of high surface roughness of thin films, fine grains and low roughness on the surface of nano-films, and improve the Finish and machining accuracy, excellent cutting performance, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

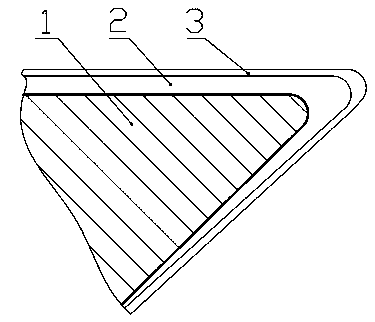

[0026] see figure 1 , embodiment 1 adopts cemented carbide tool substrate 1, and its surface deposits micron superhard film 2 and nanoscale superhard film 3 secondly, and preparation process is as follows:

[0027] (1) Substrate pretreatment: the tool substrate 1 is first ultrasonically cleaned with acetone for 20 minutes, then ultrasonically cleaned with ethanol for 20 minutes, then ultrasonically ground with diamond micropowder suspension for 20 minutes, and cleaned with an argon glow discharge plasma cleaner for 20 minutes for future use ;

[0028] (2) Deposition of crystalline micron carbon nitride film: a layer of about 10 μm thick crystalline micron carbon nitride film (micron superhard film 2 ) is directly deposited on the surface of tool substrate 1 by CVD method. CVD methods such as: radio frequency assisted HFCVD method, microwave plasma CVD method, plasma jet CVD method, etc.

[0029](3) Deposition of crystalline nano-superhard film: After the preparation of the c...

Embodiment 2

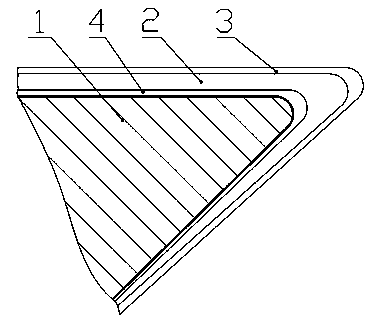

[0031] Such as figure 2 , embodiment 2 adopts cemented carbide cutter substrate 1, and its surface deposits transition layer 4, micron superhard film 2 and nanoscale superhard film 3 successively, and the preparation process is as follows:

[0032] (1) Substrate pretreatment: Take the tool substrate 1 and clean it ultrasonically with acetone for 20 minutes, and then with ethanol for 20 minutes. In order to reduce the influence of Co on the deposited diamond film, etch the cemented carbide with an acid etchant for about 2 minutes. Ultrasonic grinding with diamond micropowder suspension for 20 minutes, and cleaning with argon glow discharge plasma cleaning machine for 20 minutes for standby;

[0033] (2) Micro / nano-diamond composite transition layer deposition: Put the cemented carbide tool into the vacuum deposition equipment, and use the CVD method (bias-assisted HFCVD method, microwave plasma CVD method, plasma jet CVD method, etc.) to deposit on the tool surface A layer of...

Embodiment 3

[0037] Such as figure 2 , embodiment 3 adopts cemented carbide tool substrate 1, and its surface deposits transition layer 4, micron superhard film 2 and nanoscale superhard film 3 successively, and the preparation process is as follows:

[0038] (1) Substrate pretreatment: Take the tool substrate 1 and clean it ultrasonically for 20 minutes with acetone, then ultrasonically clean it with ethanol for 20 minutes, then ultrasonically grind it with diamond micropowder suspension for 20 minutes, and clean it with an argon glow discharge plasma cleaner for 20 minutes before use. ;

[0039] (2) Deposition of micron or nano-diamond transition layer: Put the cemented carbide tool into the vacuum deposition equipment, and use CVD method (bias-assisted HFCVD method, microwave plasma CVD method, plasma jet CVD method) to deposit a layer on the surface of the tool Micron or nanocrystalline diamond with a thickness of about 0.8 μm to obtain a micron or nanodiamond transition layer 4;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com