Aluminum-based alloy

An aluminum alloy and alloy technology, applied in the field of products working at high temperature and low temperature, can solve the problems of insufficient high temperature heating tolerance and low strength performance level of semi-finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

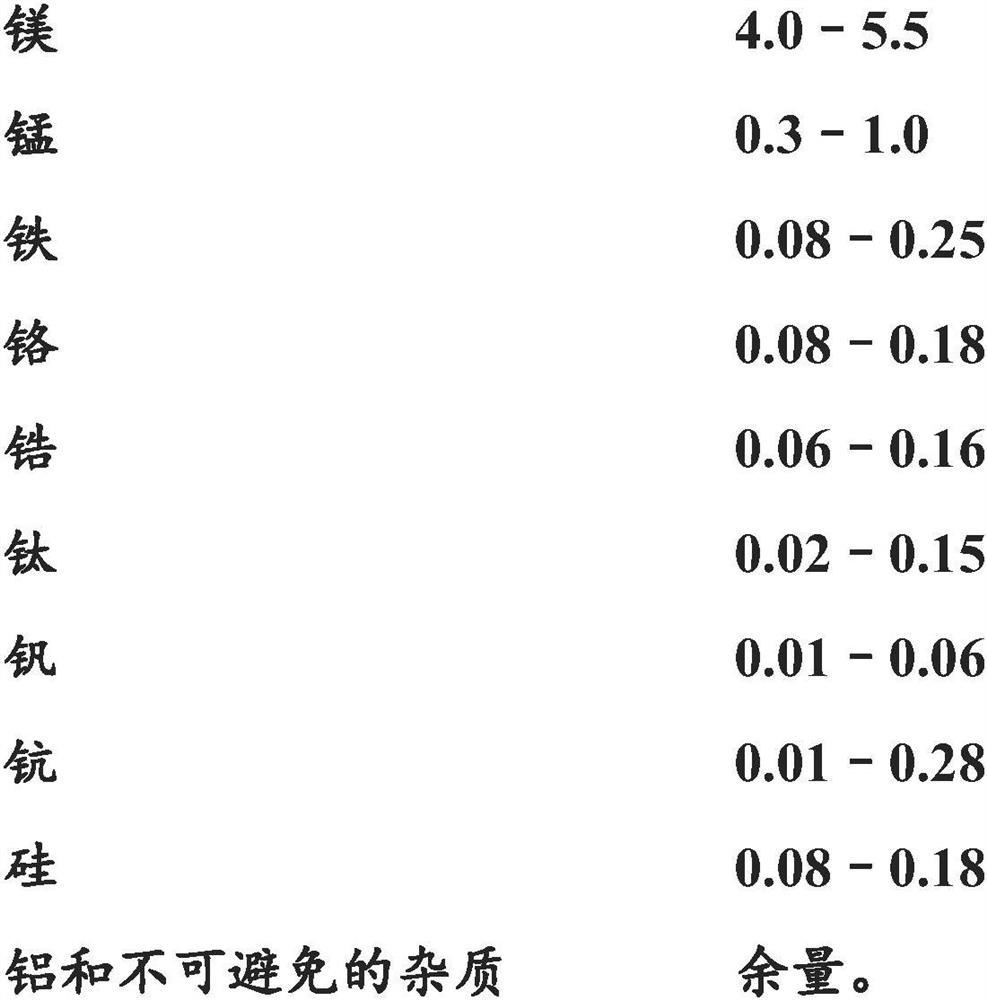

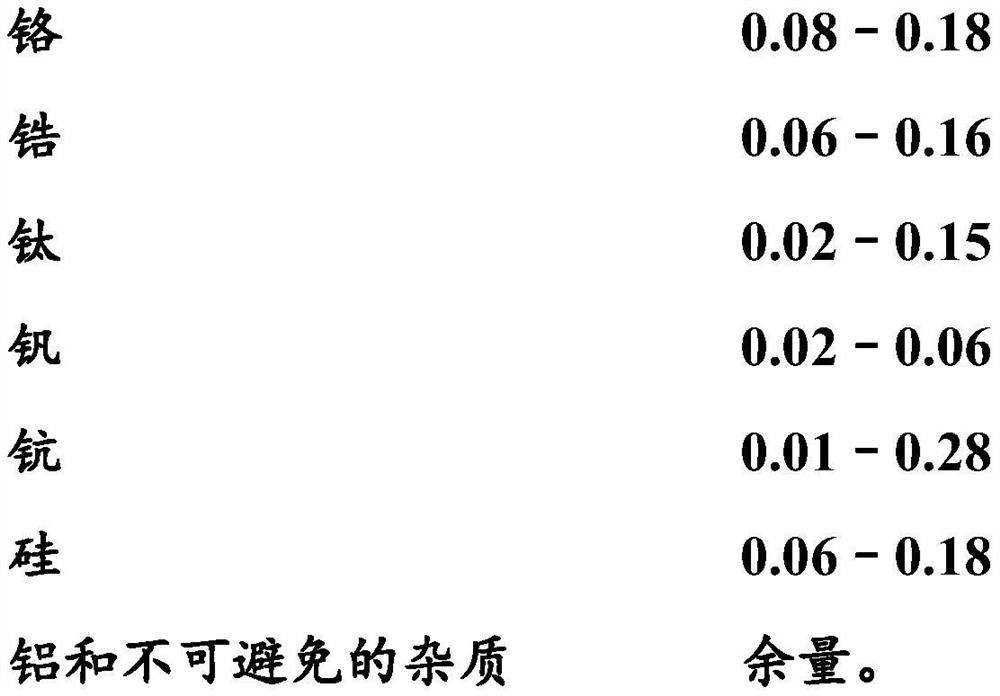

[0032] Eight alloys were prepared under laboratory conditions, and their chemical compositions are shown in Table 1.

[0033] Numbering Mg mn Fe Cr Zr Ti V sc Si Al 1 3.8 0.2 0.01 0.01 0.03 0.01 - - 0.25 margin 2 4.0 1.0 0.08 0.18 0.06 0.15 0.02 0.28 0.18 margin 3 4.1 0.5 0.15 0.10 0.16 0.02 - 0.01 0.09 margin 4 5.0 0.6 0.15 0.13 0.10 0.08 - 0.10 0.11 margin 5 5.1 0.5 0.16 0.12 0.16 05 0.04 - 0.10 margin 6 5.1 0.5 0.25 0.12 0.08 0.08 0.06 0.06 0.08 margin 7 5.5 0.6 0.15 0.08 0.10 0.09 - 0.10 0.10 margin 8 5.8 1.1 0.27 0.19 0.18 0.17 - 0.31 0.07 margin

[0034] Table 1: Chemical composition (wt%) of experimental alloys

[0035] The alloy is prepared in a laboratory induction furnace and each casting has a mass of at least 14kg. The following materials are used as charge (weight %): aluminum A99 (99.99% of Al), magnesium Mg90 (99.90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com