Low internal resistance and high power graphene super capacitor electrode sheet and manufacturing method

A technology for supercapacitors and graphene electrodes, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., and can solve problems such as difficulty in the preparation of graphene electrode sheets, low density of graphene materials, and low solid content of slurry , achieve good mechanical properties, increase specific energy, and excellent specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

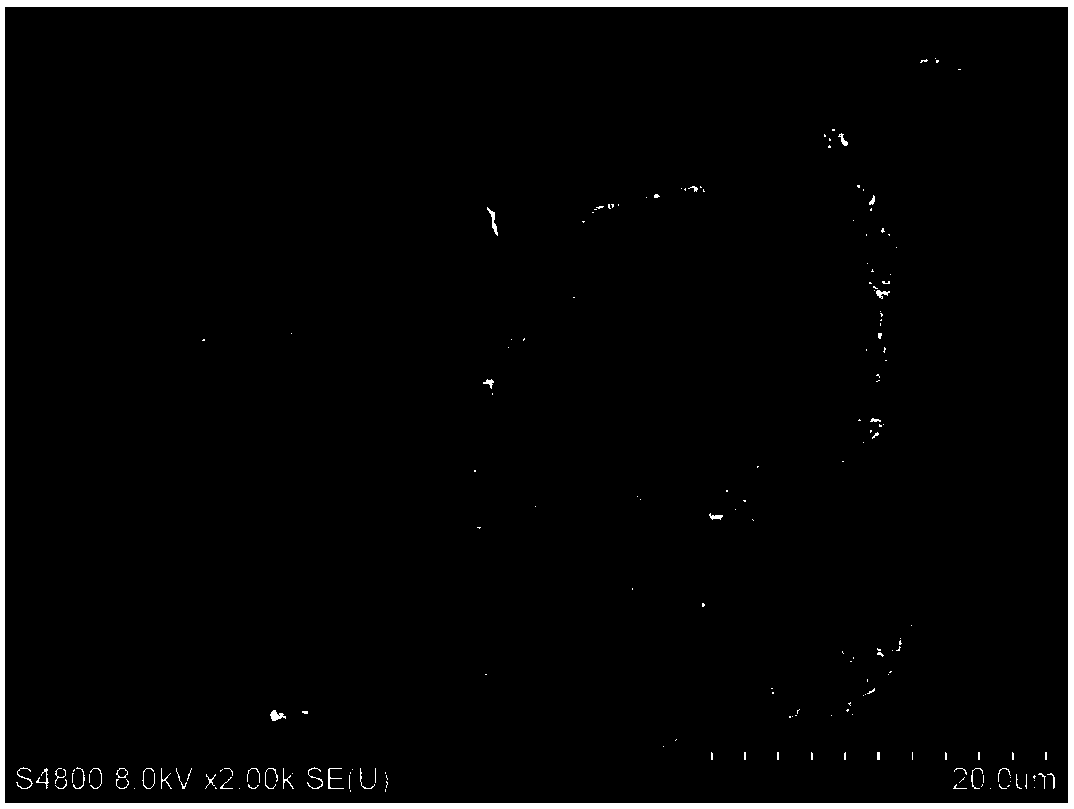

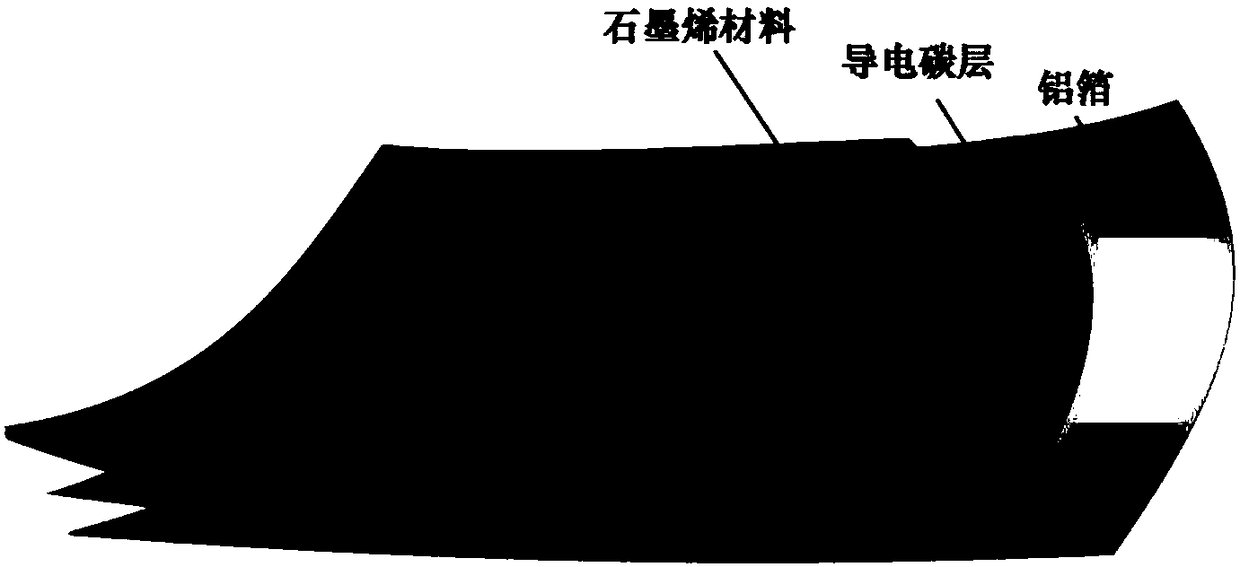

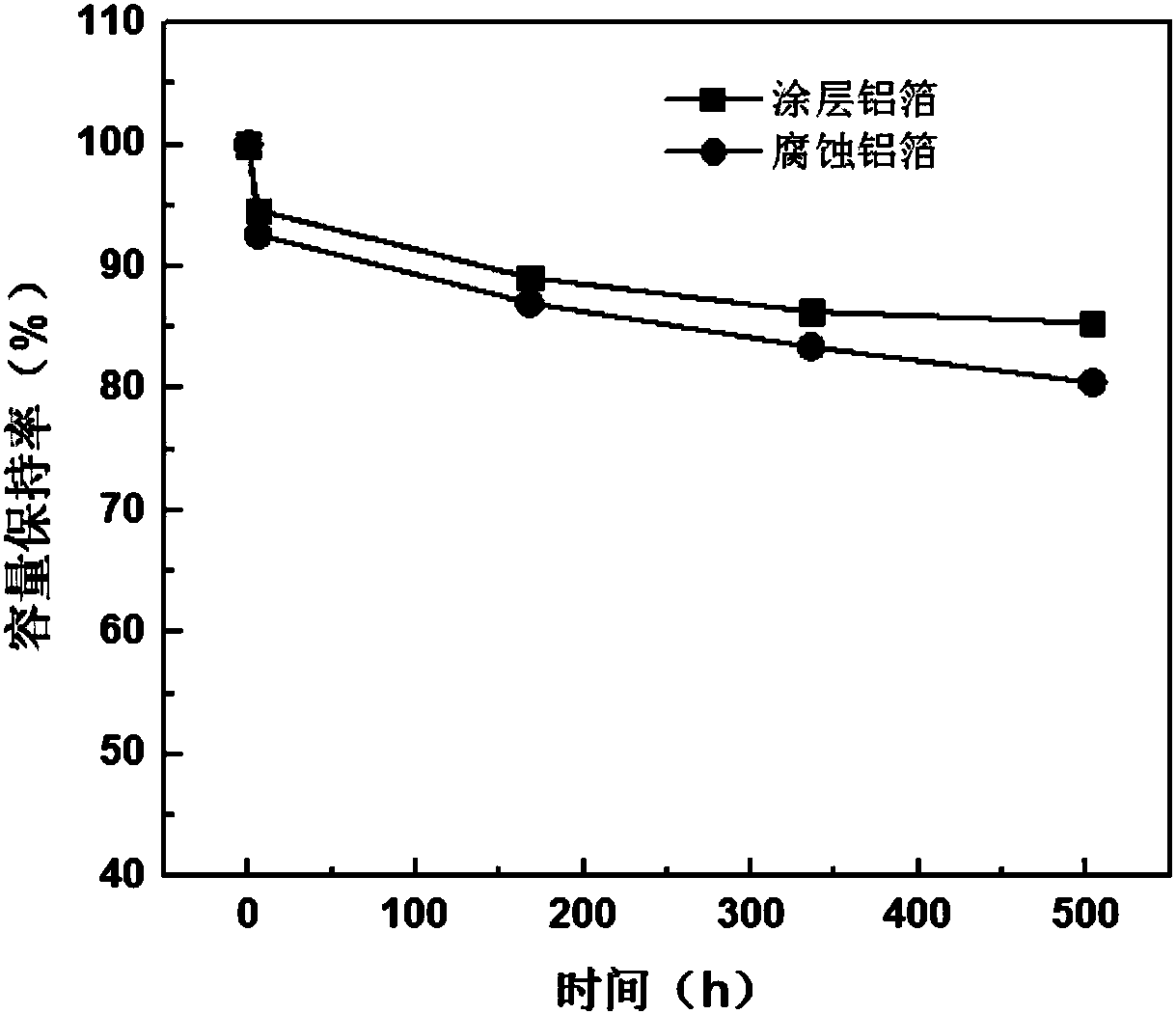

Embodiment 1

[0033] The graphene, the conductive agent and the adhesive are uniformly mixed in advance according to the mass percentage of 88:6:6, and the above-mentioned mixture is super-shear mixed at a shear rate of 10000rpm, and then under a pressure of 150MPa, the dry mixture is sequentially Carry out "vertical" and "horizontal" two-step rolling to obtain a graphene carbon film with uniform thickness. The specific surface area of described graphene is 1000-1500m 2 / g, the tap density is 0.2-0.5g / cm 3, the pore size is 2-10nm, the particle size is 7-10μm, the carbon content is greater than 99.8%, the oxygen-containing functional group content is less than 0.35meq / g, the water content is less than 0.40%, and the total metal content is less than 100ppm. Its microscopic appearance is as follows figure 1 shown. The conductive agent is a three-phase composite conductive agent of conductive carbon black, carbon nanotubes and graphene, and the mass ratio of the three is 1:1:1. The compos...

Embodiment 2

[0037] The graphene, conductive agent and adhesive are pre-mixed uniformly according to the mass percentage of 90:4:6, and the above-mentioned mixture is super-sheared and mixed under the condition of a shear speed of 11000rpm, and then under a pressure of 200MPa, the dry mixture is successively Carry out "vertical" and "horizontal" two-step rolling to obtain a graphene carbon film with uniform thickness. The specific surface area of described graphene is 1000-1500m 2 / g, the tap density is 0.2-0.5g / cm 3 , the pore size is 2-10nm, the particle size is 7-10μm, the carbon content is greater than 99.8%, the oxygen-containing functional group content is less than 0.35meq / g, the water content is less than 0.40%, and the total metal content is less than 100ppm. The conductive agent is a three-phase composite conductive agent of conductive carbon black, carbon nanotubes and graphene, and the mass ratio of the three is 1:1.1:0.9. The composite conductive agent powder is obtained b...

Embodiment 3

[0041] The graphene, conductive agent and adhesive are pre-mixed uniformly according to the mass percentage of 85:8:7, and the above-mentioned mixture is super-sheared and mixed under the condition of a shear speed of 9000rpm, and then under a pressure of 250MPa, the dry mixture is successively Carry out "vertical" and "horizontal" two-step rolling to obtain a graphene carbon film with uniform thickness. The specific surface area of described graphene is 1000-1500m 2 / g, the tap density is 0.2-0.5g / cm 3 , the pore size is 2-10nm, the particle size is 7-10μm, the carbon content is greater than 99.8%, the oxygen-containing functional group content is less than 0.35meq / g, the water content is less than 0.40%, and the total metal content is less than 100ppm. The conductive agent is a three-phase composite conductive agent of conductive carbon black, carbon nanotubes and graphene, and the mass ratio of the three is 1:0.9:1.1. The composite conductive agent powder is obtained by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com