Polymer comprising amide and ester groups method for production and use thereof

An amide-based, polymer-based technology for use in amides and esters to address incomplete, high exhaust filter and exhaust air loads, elevated distilled water contamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

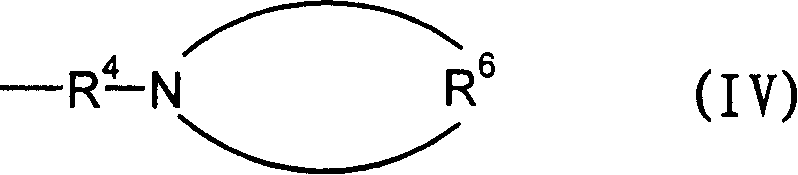

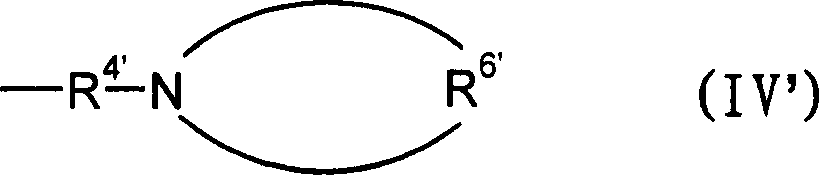

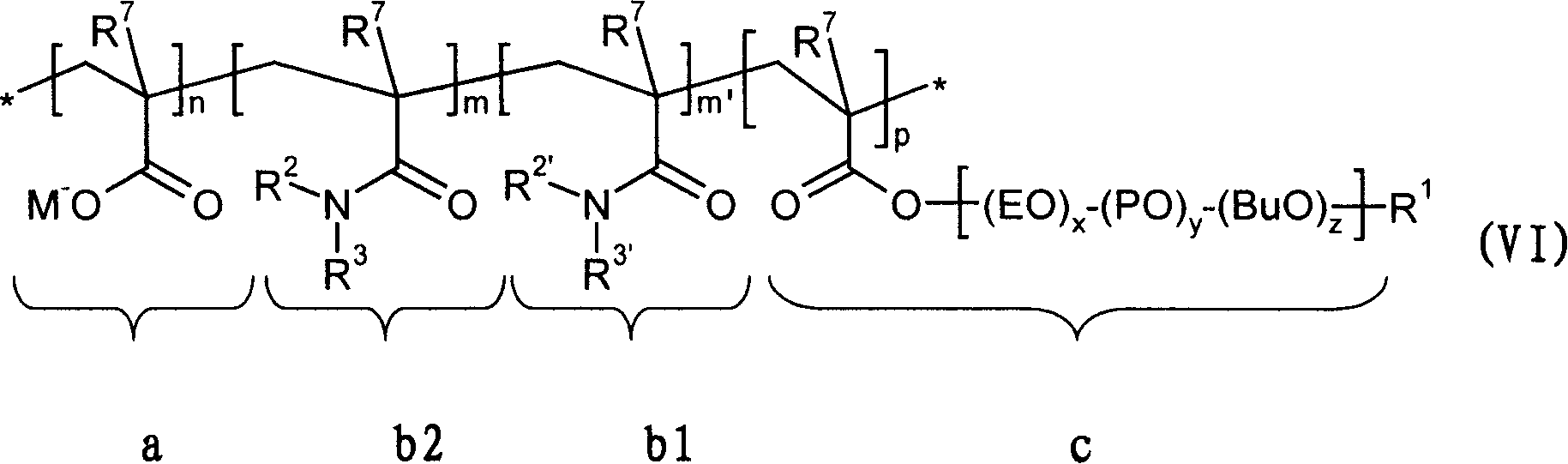

Method used

Image

Examples

Embodiment

[0081] Example series 1

[0082] First step: Esterification / amidation and anhydride formation

[0083] A reaction vessel with stirrer, thermometer, vacuum connection and distillation unit was prefilled with 960 g of a 40% aqueous solution of polymethacrylic acid with an average molecular weight of 5000 g / mol. Under stirring, 10 g of 50% sulfuric acid and 16 g of a copolymer formed from ethylene oxide and propylene oxide with an EO / PO ratio of 70:30 and a molecular weight of M w 2000 g / mol, with methoxy groups on one side and primary amino groups on the other side. 1200 g of polyethylene glycol endcapped on one side with methoxy groups and having an average molecular weight of 1100 g / mol were added in the melt, and the reaction mixture was heated slowly to 160° C. with stirring. Water is continuously distilled off during this process. Once the reaction mixture reached 160° C., the mixture was stirred at this temperature for 30 minutes and continued to distill off water. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com