Embossed furniture assembling equipment

A technology for assembling equipment and furniture, applied in the direction of manufacturing tools, wood processing utensils, etc., can solve the problems of no automatic machines, waste of manpower and time, and achieve the effect of reducing labor costs, improving efficiency, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

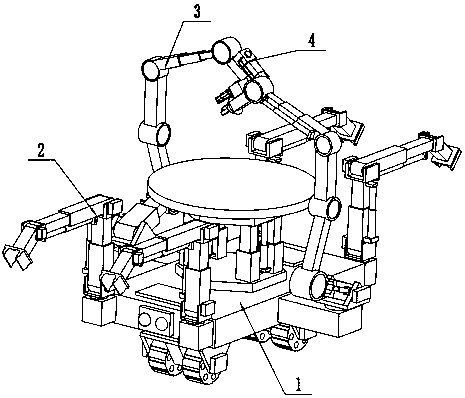

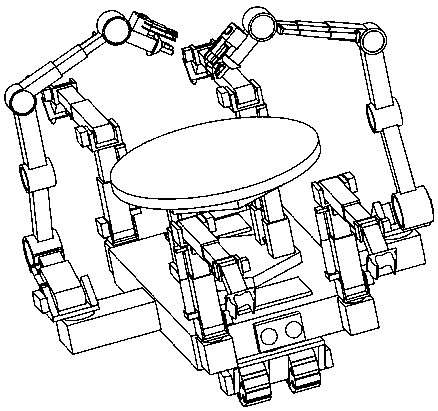

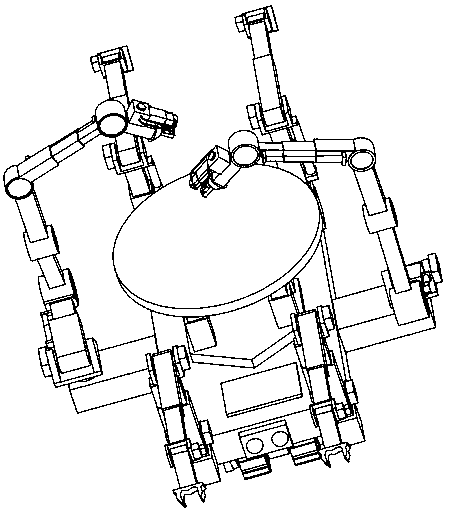

[0021] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, a relief furniture assembly equipment includes a base part 1, a grabbing part 2, a rotary nail gun part 3, and a glue part 4, and the grabbing part 2 is fixedly installed on the bottom plate 101 of the base part 1; The left and right sides of the bottom plate 101 of the base part 1 are respectively fixedly installed with the intelligent control box 301 of the rotating nail gun part 3;

[0022]Further, the base part 1 includes a bottom plate 101, a power controller 102, a first image acquisition and processing system 103, a wheel support 104, a first moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com