Wind power blade pultrusion enhanced panel facilitating resin flowing and manufacturing method of wind power blade pultrusion enhanced panel

A technology for wind turbine blades and resin flow, applied in the field of pultrusion plates, can solve the problems of affecting the bonding strength of blade plates, the uniformity of resin infusion can not be self-balanced, and reduce the mechanical properties of blades, so as to reduce the risk of excessive or lack of glue, The effect of improving the uniformity of infusion and improving the bonding strength between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

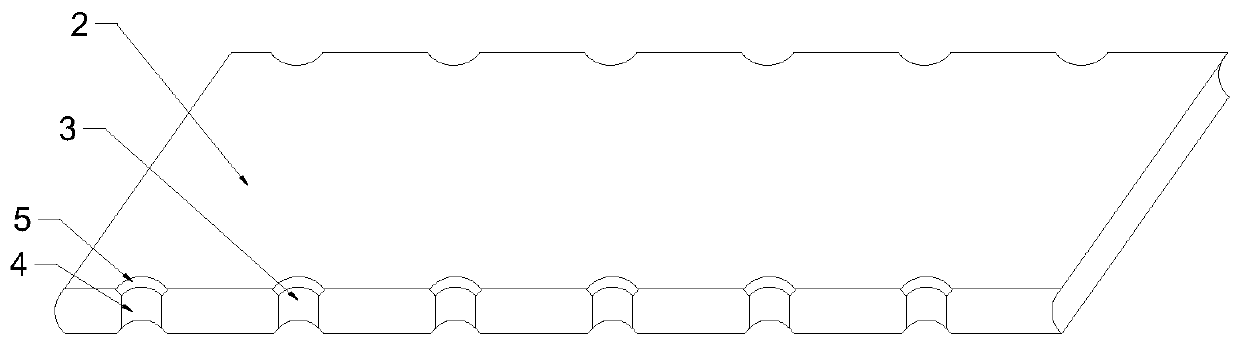

[0034] Figure 5 The first method of pultrusion showing the pre-curing stage:

[0035] S1. Stacking multiple layers of fiber sheets in parallel, infiltrating the stacked fiber sheets through the resin tank 6, so that the resin is immersed between the fiber sheets of each layer;

[0036] S2. The fiber sheet is pre-cured by the resin in the curing box 7, and the multi-layer fiber sheet is pre-cured into a layer of pultrusion board;

[0037] S3. The pre-cured pultruded sheet passes through the flow channel forming belt 8, and the punch 9 of the flow channel forming belt 8 squeezes the pultruded sheet on the left and right sides of the pultruded sheet to form several flow channels 3; The plate 2 is wound into a coil;

[0038] S4. Lay the multi-layer pultruded boards 2, and then infiltrate and solidify them into a pultruded reinforced board 1 through resin infiltration.

[0039] The length of the pultruded reinforced plate 1 can be infinitely extended theoretically, and can be s...

Embodiment 2

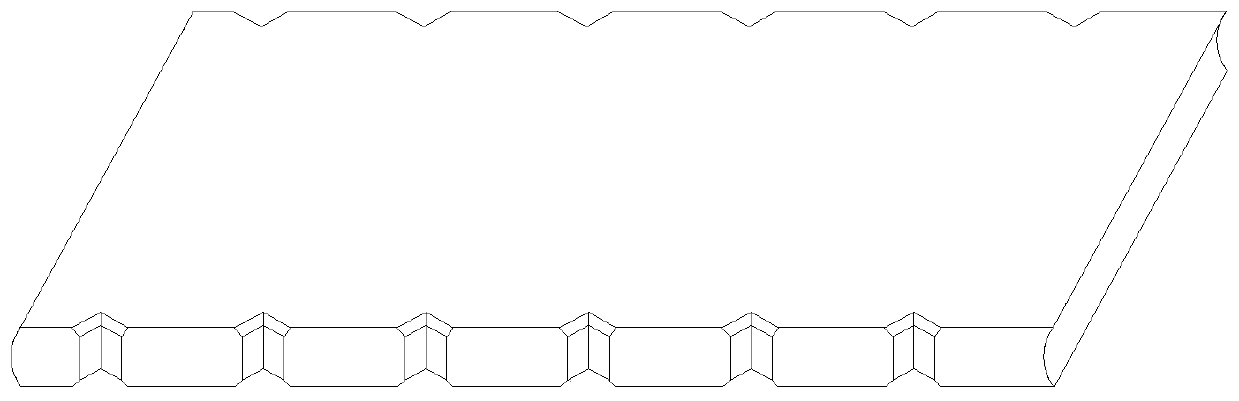

[0043] Image 6 It shows another method of pultruding the flow channel of the pultruded sheet in the pre-curing stage: the difference between this method and the first method is that in step S3: the pultruded sheet is passed through the flow channel while pre-curing The trough forming belt 8 and the flow trough forming belt 8 extrude the pultruded sheet on the left and right sides of the pultruded sheet 2 to form several flow troughs 3 . The convex mold forming side of the flow channel forming belt 8 is located in the curing box 7, which is convenient for forming the flow channel while pre-curing the pultruded sheet.

[0044] The method of reprocessing and forming in the post-curing stage may be to process flow grooves on the side of the pultruded sheet by means of compression molding, acid etching or grinding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com