A soft crawling adsorption robot

A robot and software technology, applied in motor vehicles, transportation and packaging, etc., can solve the problems of four-legged software robots difficult to achieve continuous crawling forward, bonding and falling off, and inability to effectively control inflation and deflation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 A soft crawling adsorption robot

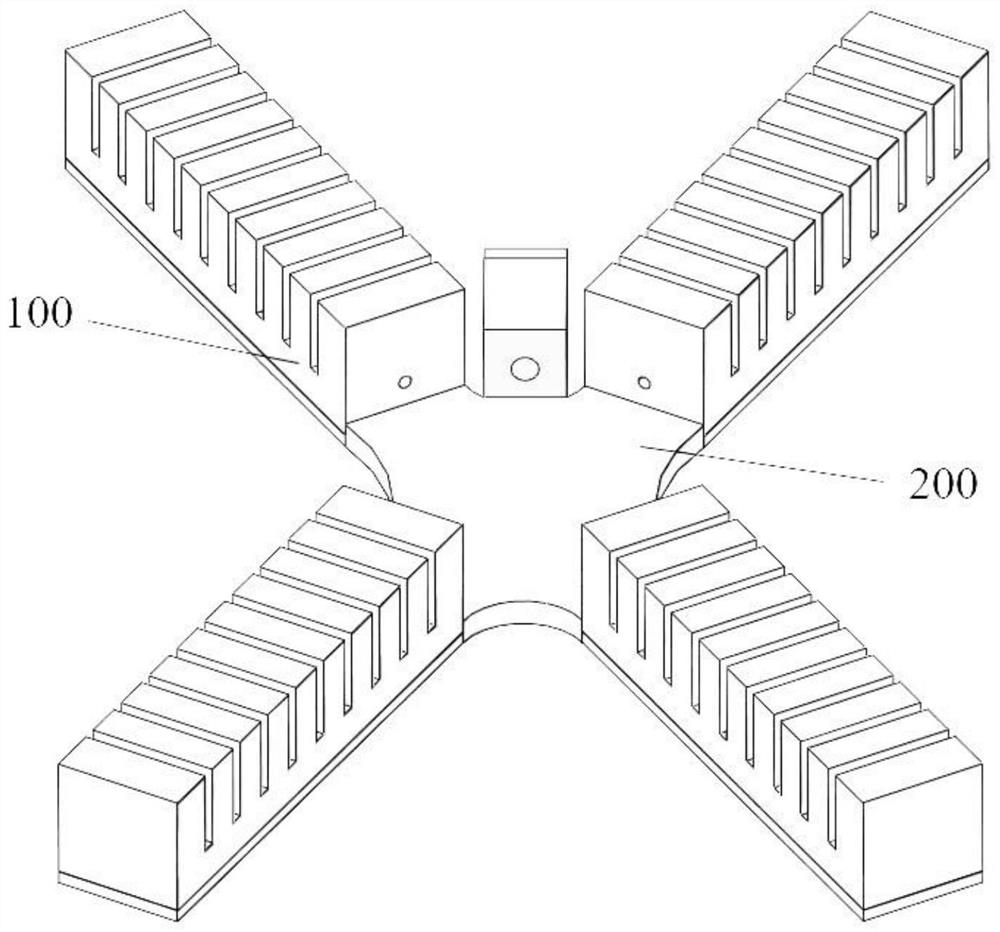

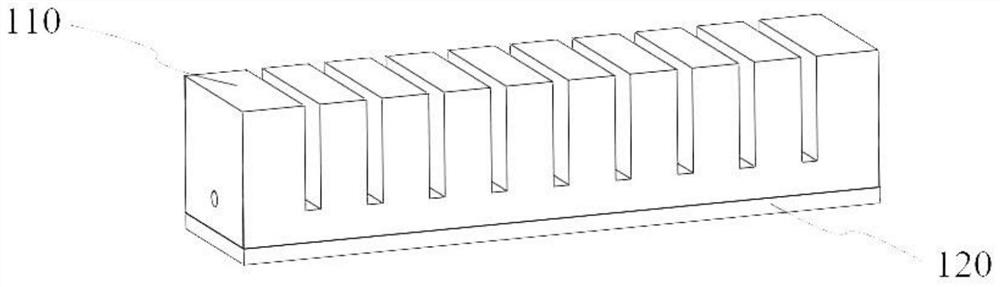

[0058] A kind of soft crawling adsorption robot of the present invention comprises crawling limb 100 and crawling base 200 ( figure 1 ), both of which are made of silicone. Reptiles 100( figure 2 ) including the pneumatic network 110 ( image 3 ) and bottom layer 120 ( Figure 4 ), through the adhesive bonding of the silicone material itself ( Figure 5 ).

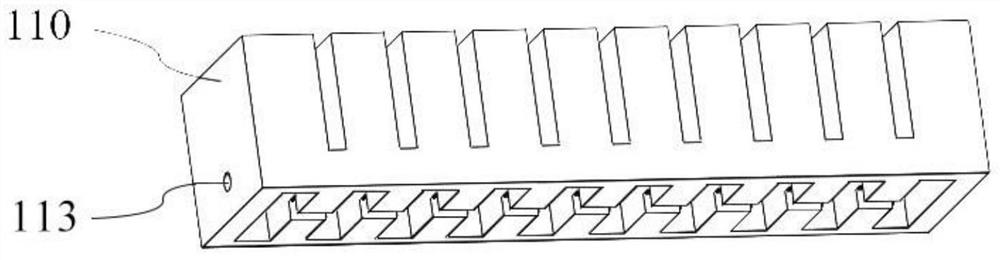

[0059] like image 3 As shown, the overall appearance of the pneumatic network 110 is comb-shaped, and is composed of ten comb units arranged in parallel. Wherein, the comb unit is hollow, the comb unit is partially connected with the unit, and there is a groove in the middle of the bottom of the connection. Figure 7 is a bottom view of the structure of the pneumatic network 110, Figure 8 is a front view of the construction of the pneumatic network 110, Figure 9 is the pneumatic network 110 at Figure 7 and Figure 8 The cross-section at A-A in the middl...

Embodiment 2

[0062] Embodiment 2 The making of soft crawling adsorption robot

[0063] (1) Prepare emulsion silica gel

[0064] Emulsion silica gel (Dragon Components A and B of Silicones 30) are mixed and stirred evenly in a ratio of 1:1, prepared into a viscous shape, put into a vacuum machine, and the air bubbles are removed to form a transparent emulsion, which is ready for use.

[0065] (2) Making the pneumatic network of reptile limbs

[0066] According to the shape, size and structure of the crawler limb pneumatic network 110, the bottom mold of the crawler limb pneumatic network 110 is designed and manufactured ( Figure 13 ) and peripheral mold ( Figure 14 ). The above two parts of the mold are assembled together to form the overall structure of the pneumatic network 110 mold ( Figure 15 ). Pour the prepared latex silica gel into the Figure 15 In the mold shown, let stand for 12 to 16 hours. After the emulsion-like silica gel is dried and cured, it is demoulded to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com