Heating temperature control box of aircraft windshield glass

A temperature control box and windshield technology, applied in aircraft parts, deicing devices, transportation and packaging, etc., can solve the problems of difficult adjustment process, poor interchangeability, and large temperature dispersion, saving manpower and material resources and shortening maintenance. time, the effect of guaranteeing interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

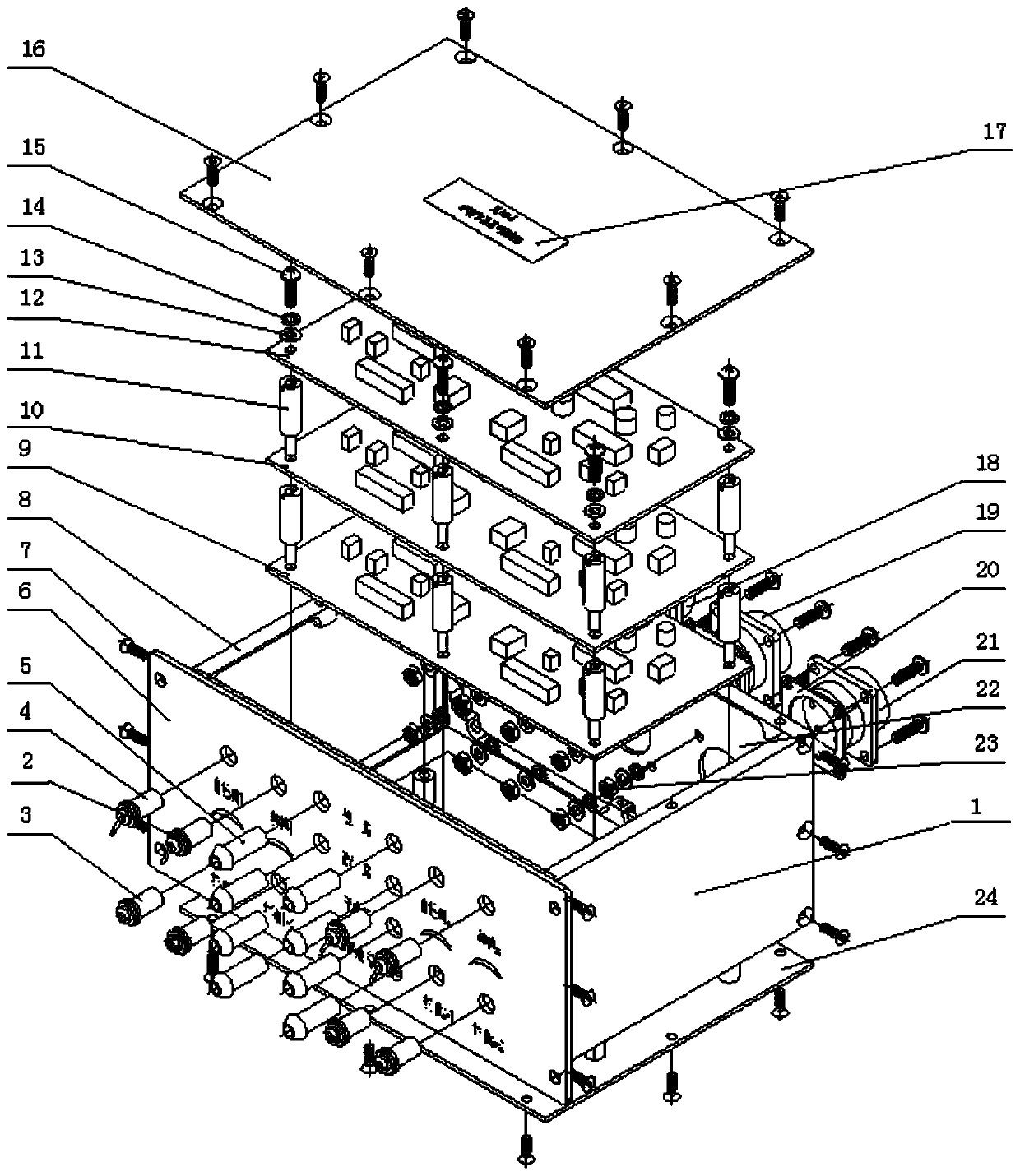

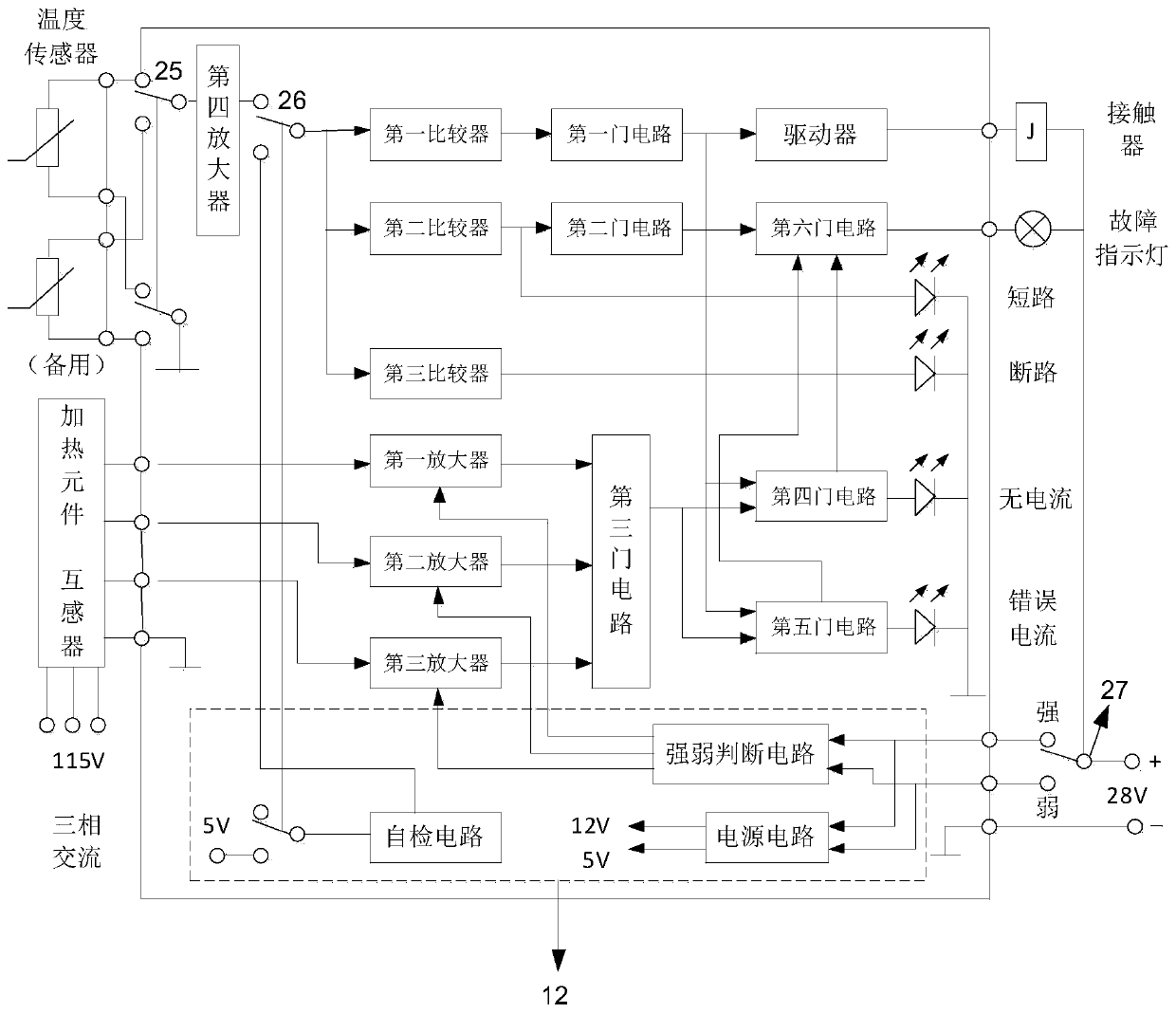

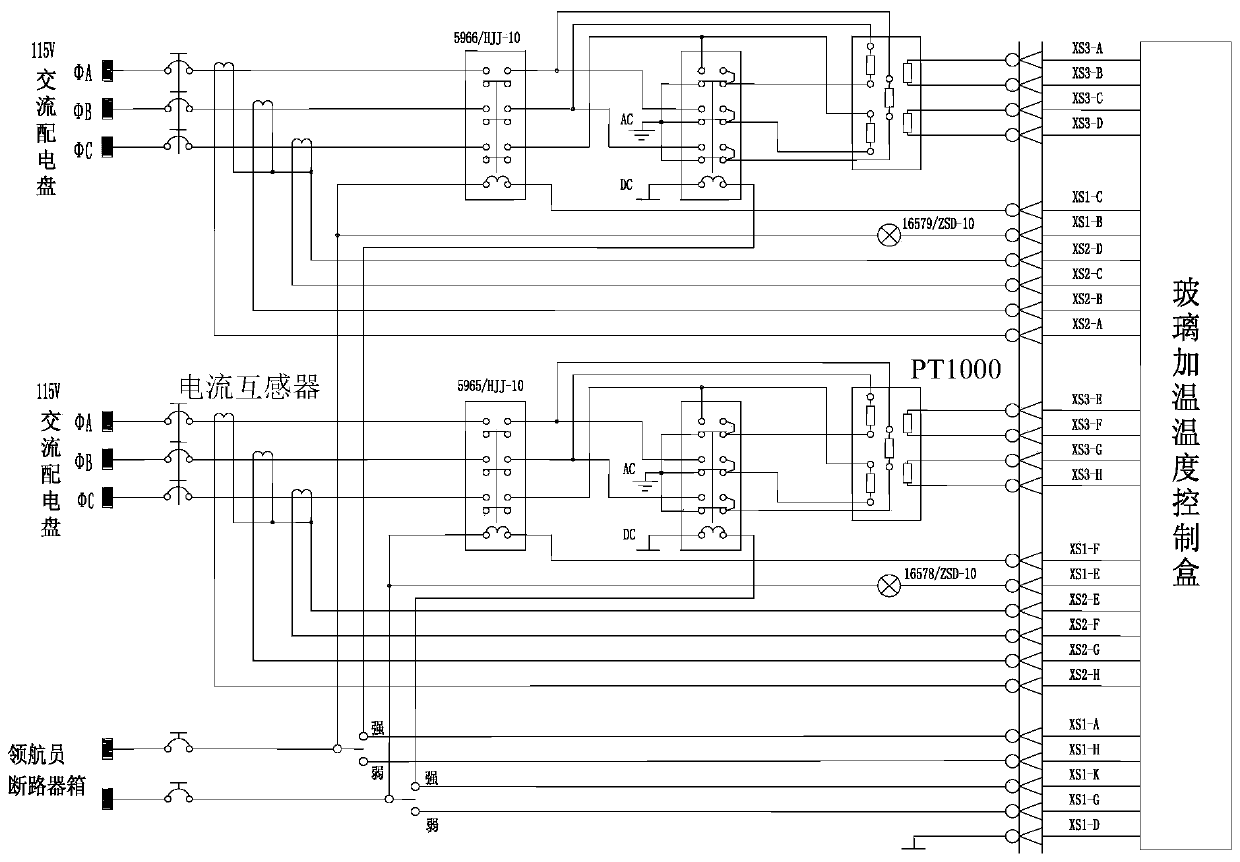

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

[0033] see figure 1 , the present invention is a glass heating temperature control box, the glass heating temperature control box includes a box body 1, a front panel 6, a rear panel 22, a bottom plate 24, a cover plate 16 and two side panels 8, a front panel 6, a rear panel The panel 22 and the two side plates 8 are fixedly connected by several first screws 7 to form a quadrilateral, that is, the side walls of the temperature control box. The upper ends of the four side plates are fixedly connected to the cover plate 16, and the lower ends are fixedly connected to the bottom plate 24. The front panel 6 , the rear panel 22 , the bottom plate 24 , the cover plate 16 and the two side plates 8 together constitute the box body 1 ; the cover plate 16 is provided with a label 17 .

[0034] The front panel 6 is divided into a left glass area and a right glass area, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com