Beef jerky energy-saving container

A technology for beef jerky and containers, applied in containers, anti-rot containers, transportation and packaging, etc., can solve the problems of moisture not being discharged in time, energy waste, etc., to speed up drying, solve energy waste, and increase contact area effect

Inactive Publication Date: 2019-05-10

贵州金家食品有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention intends to provide an energy-saving container for beef jerky to solve the technical problem that the existing beef jerky container needs to be manually stirred during use, and the moisture emitted in the beef cannot be discharged in time, resulting in energy waste

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

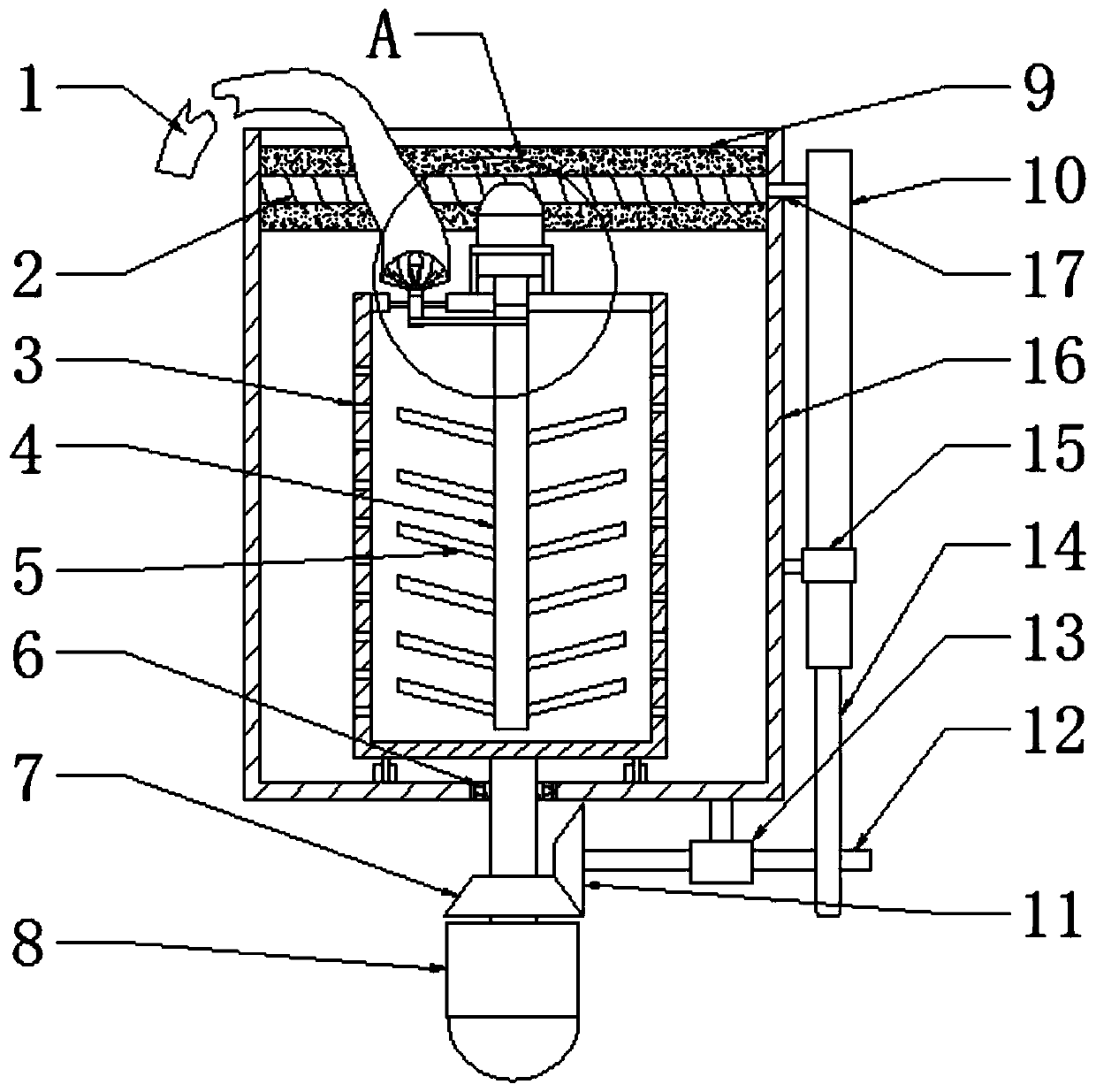

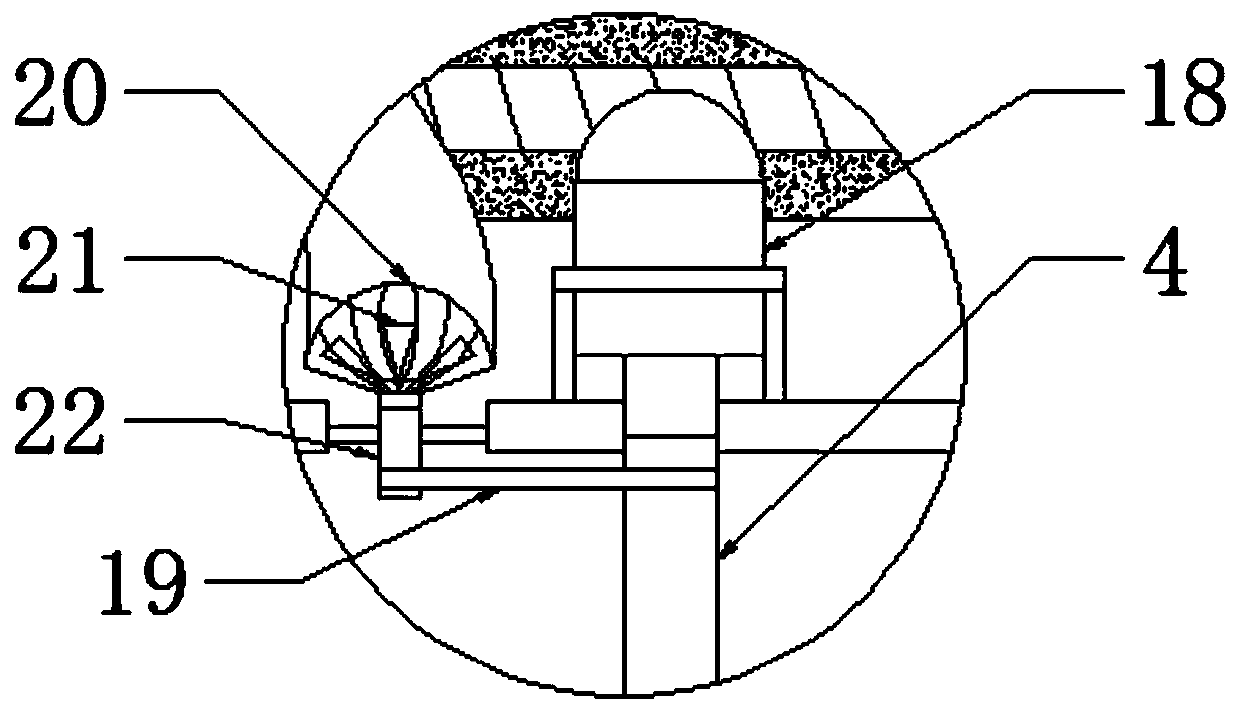

The invention discloses a beef jerky energy-saving container, and belongs to the field of beef jerky processing equipment. The beef jerky energy-saving container comprises a barrel body, the barrel body comprises an inner barrel and an outer barrel, the inner barrel is connected in the outer barrel, a gap is reserved between the inner barrel and the outer barrel, a plurality of air holes are formed in the barrel wall of the inner barrel, a supporting frame is arranged at the top of the inner barrel, a stirring motor and a dehumidifying mechanism are arranged on the supporting frame, an outputshaft of the stirring motor is connected with a stirring shaft, the stirring shaft extends into the inner barrel, the dehumidifying mechanism comprises a dehumidifying fan and a coil spring, the dehumidifying fan comprises a rotating shaft and fan blades, one end of the coil spring is connected with the stirring shaft, the other end of the coil spring is connected with the rotating shaft, the rotating shaft is further rotationally connected to the supporting frame, and the fan blades are connected to the top of the rotating shaft. According to the beef jerky energy-saving container, the stirring motor is arranged at the top of the inner barrel, so that the coil spring can store energy when the stirring motor operates, the dehumidifying fan can discharge a large amount of moisture from a high position, so that the energy-saving effect is achieved, and the problem of energy waste in the prior art is solved.

Description

technical field [0001] The invention relates to the field of beef jerky processing equipment, in particular to an energy-saving container for beef jerky. Background technique [0002] In the processing of beef jerky, one step is to dehydrate and dry the boiled beef base. There are three drying methods currently used, namely baking, air-drying and frying. Baking and air-drying take more time. Frying also needs to be baked or air-dried to a certain extent before frying. In addition to taking time, it is also unhealthy because of frying. [0003] In this regard, a drying method of beef jerky combined with hot air and microwave drying has also been proposed in the processing industry of beef jerky, which can solve the above-mentioned defects, but the beef to be dried in the prior art is all packed in conventional containers. Intermittent stirring is required during the drying process, and there is no structure in the container that can stir, so it is usually stirred manually. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): B65D81/18B65D81/26B01F7/16

Inventor 金武飞金祖汉

Owner 贵州金家食品有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap