High-pressure and superhigh pressure canned-motor pump

An ultra-high pressure, shielded pump technology, applied in the direction of pumps, pump components, pump devices, etc., can solve the problems of unreliable sealing, inconvenient installation and maintenance, difficult connection of motor stator leads, etc., to achieve reliable sealing and convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

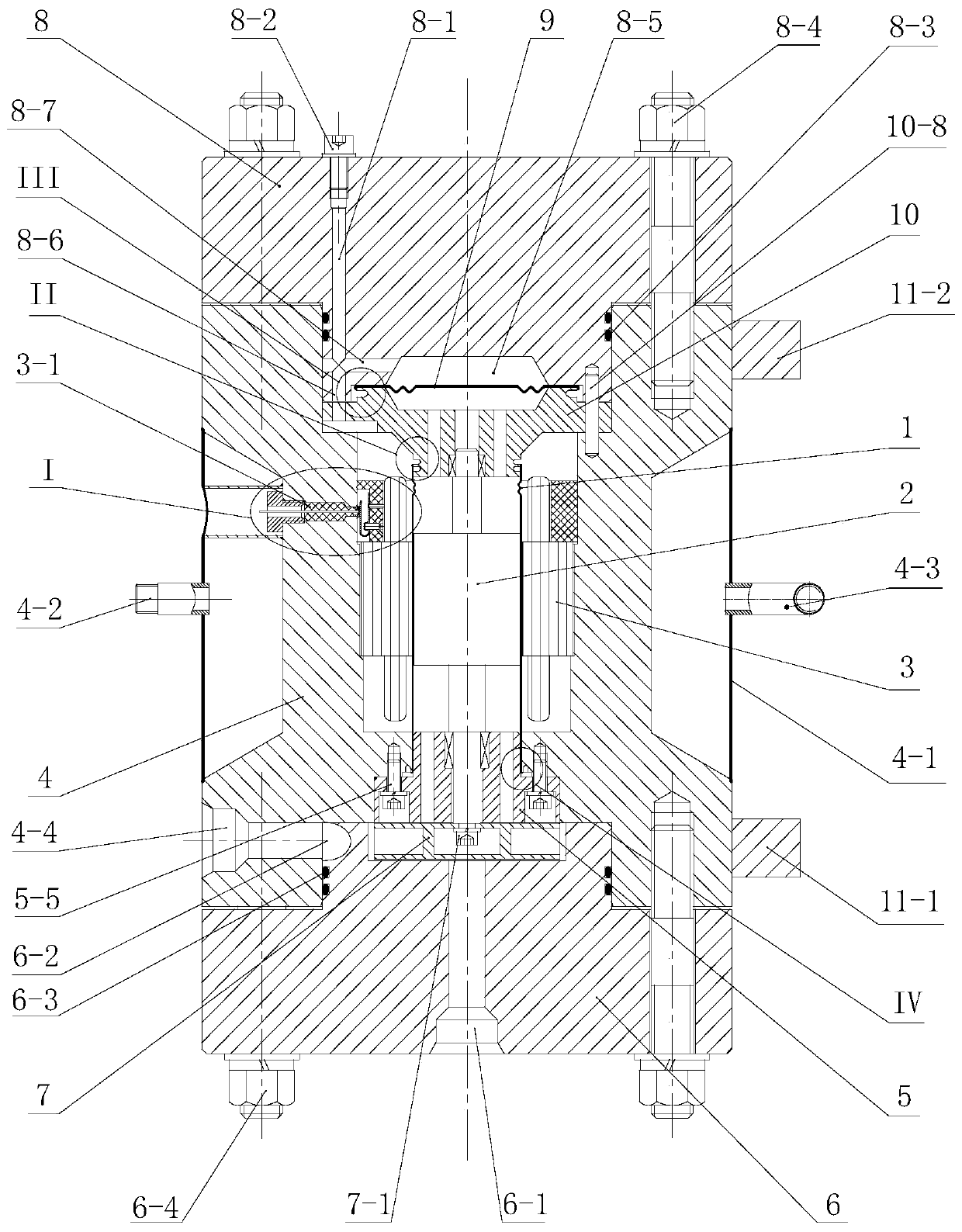

[0038] Such as figure 1 , the present invention consists of a pump head 6, an impeller 7, a motor housing 4, a motor stator 3, a motor lead assembly 3-1, a shielding sleeve 1, a motor rotor 2, a pump head bearing assembly 5, a rear cover 8, and a rear cover bearing Assembly 10, pressure balance diaphragm 9, support A 11-1, support B11-2 constitute.

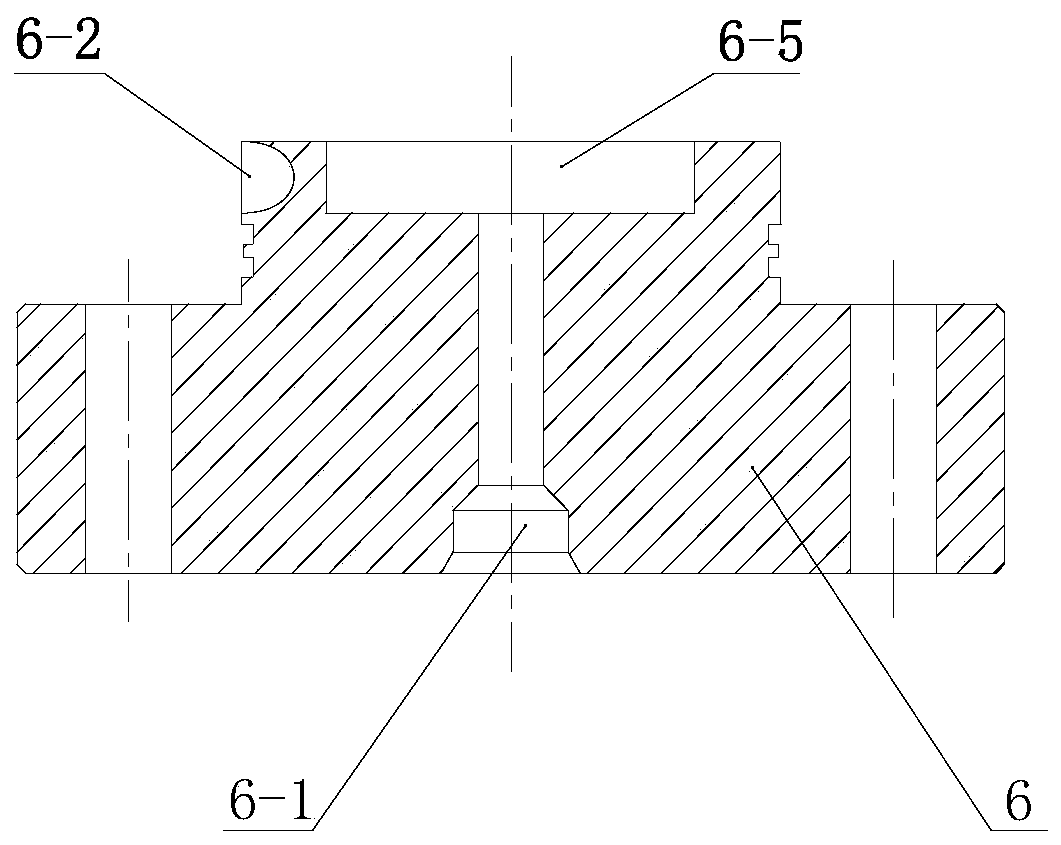

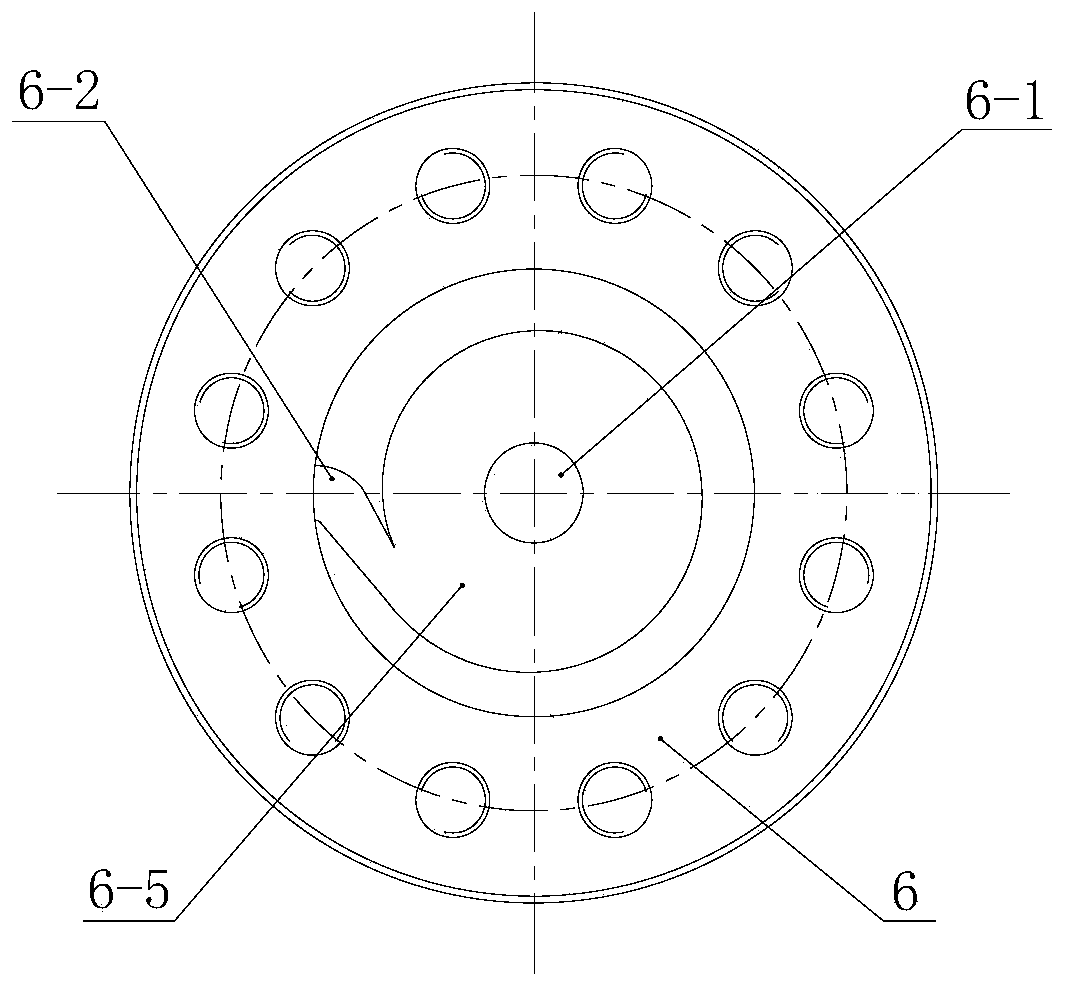

[0039] Such as figure 2 , image 3 As shown, the pump head 6 is a flat cover with a boss. S30408 stainless steel forgings are selected. A through hole is set at the axis of the flat cover as the pump inlet 6-1. The volute chamber 6-5, the volute chamber outlet 6-2 is set on the cylindrical surface of the radial boss of the pump volute chamber 6-5, the bottom of the cylindrical surface of the boss is provided with 2 sealing grooves, and the flat cover is evenly distributed on the electric pump 6 bolt h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com