Automatic powder weighing device

An automatic weighing device and powder technology, applied in the field of powder weighing, can solve the problems of low powder micro-weighing efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

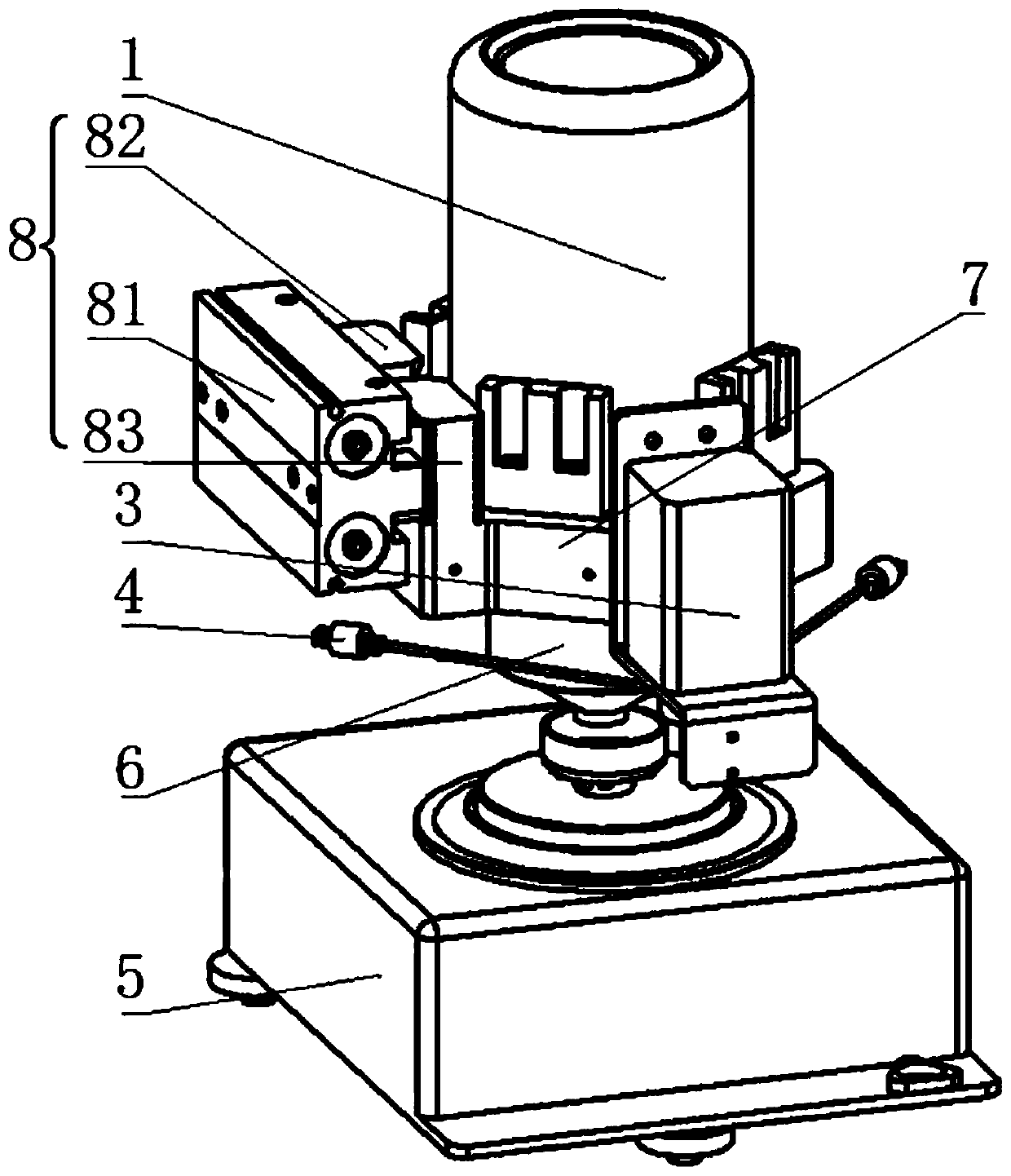

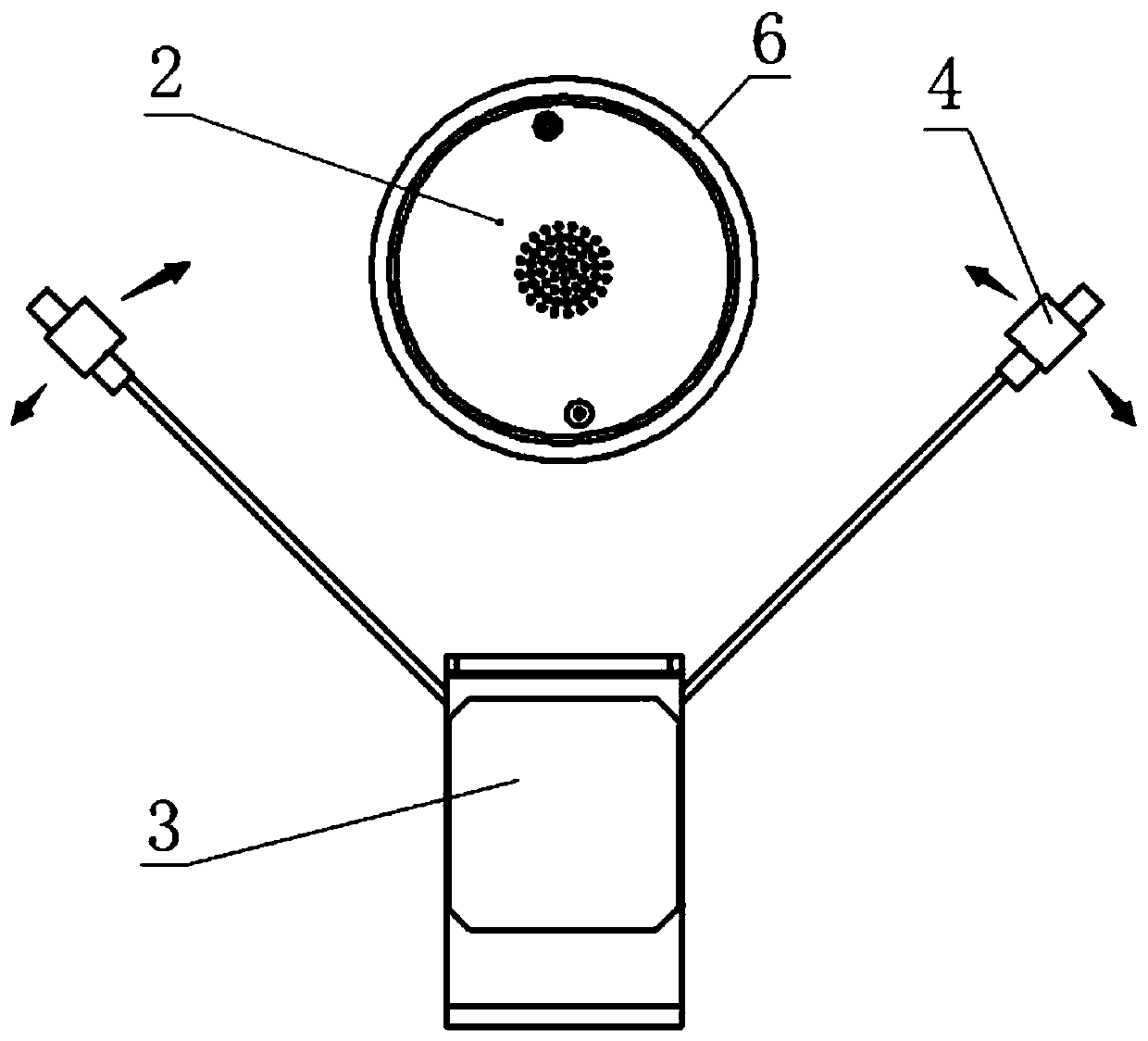

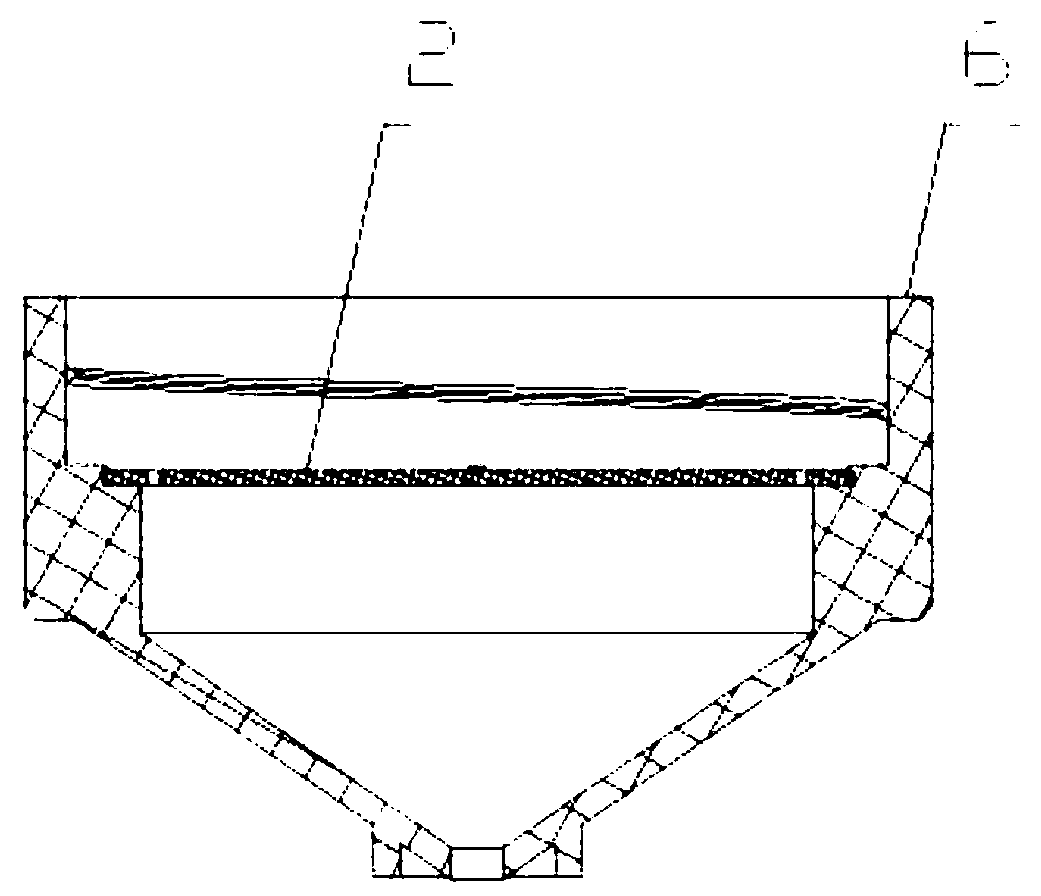

[0036] see figure 1 , figure 2 , Figure 9 , figure 1 It is a structural schematic diagram of an automatic weighing device for powder provided by the present invention, figure 2 It is a schematic diagram of the structure of the hammer, partition and cover of the automatic weighing device for powder. Figure 9 It is a structural schematic diagram of a plurality of small holes of the automatic weighing device provided by the present invention. The automatic weighing device of the powder comprises: a container 1, a partition 2, a motor 3, a percussion hammer 4, an electronic balance 5 and a control system. The outlet of the container 1 points vertically downward to the horizontal plane for containing the powder; the separator 2 is detachably arranged at the outlet of the container 1, and a plurality of small holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com