An automatic weighing and boxing device for powdery explosives

A technology of automatic weighing and pyrotechnics, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of dust explosion, high risk, and high work intensity, so as to eliminate dust explosion, improve the working environment, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

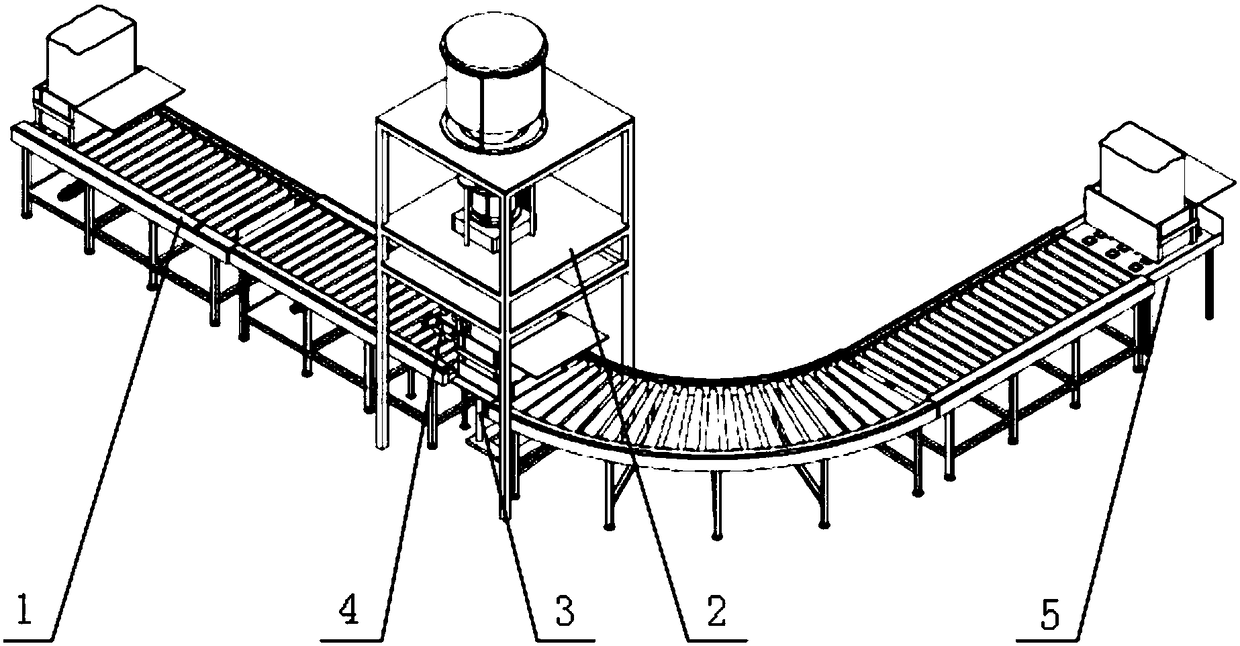

[0029] This embodiment is an automatic weighing and boxing device for powdered explosives.

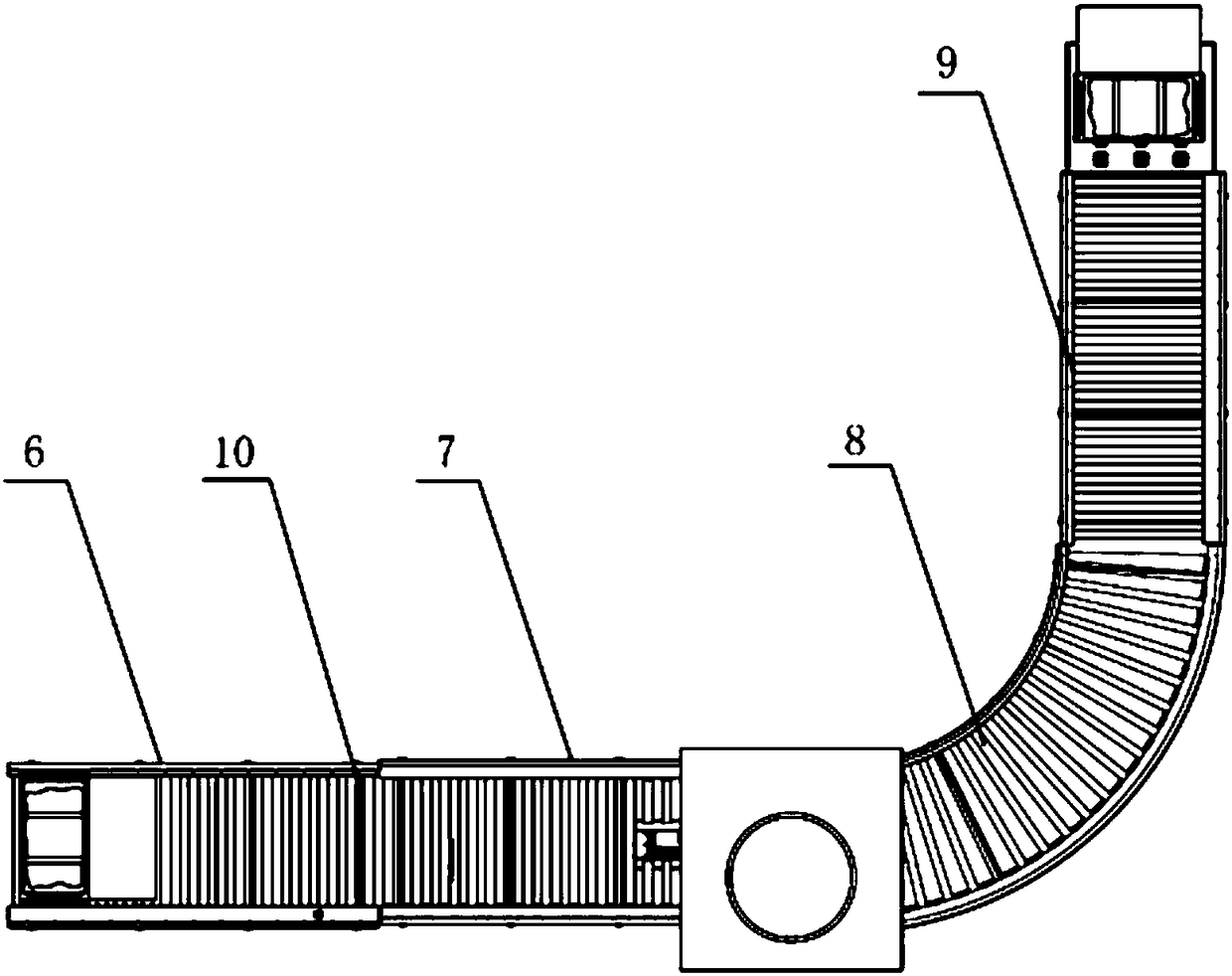

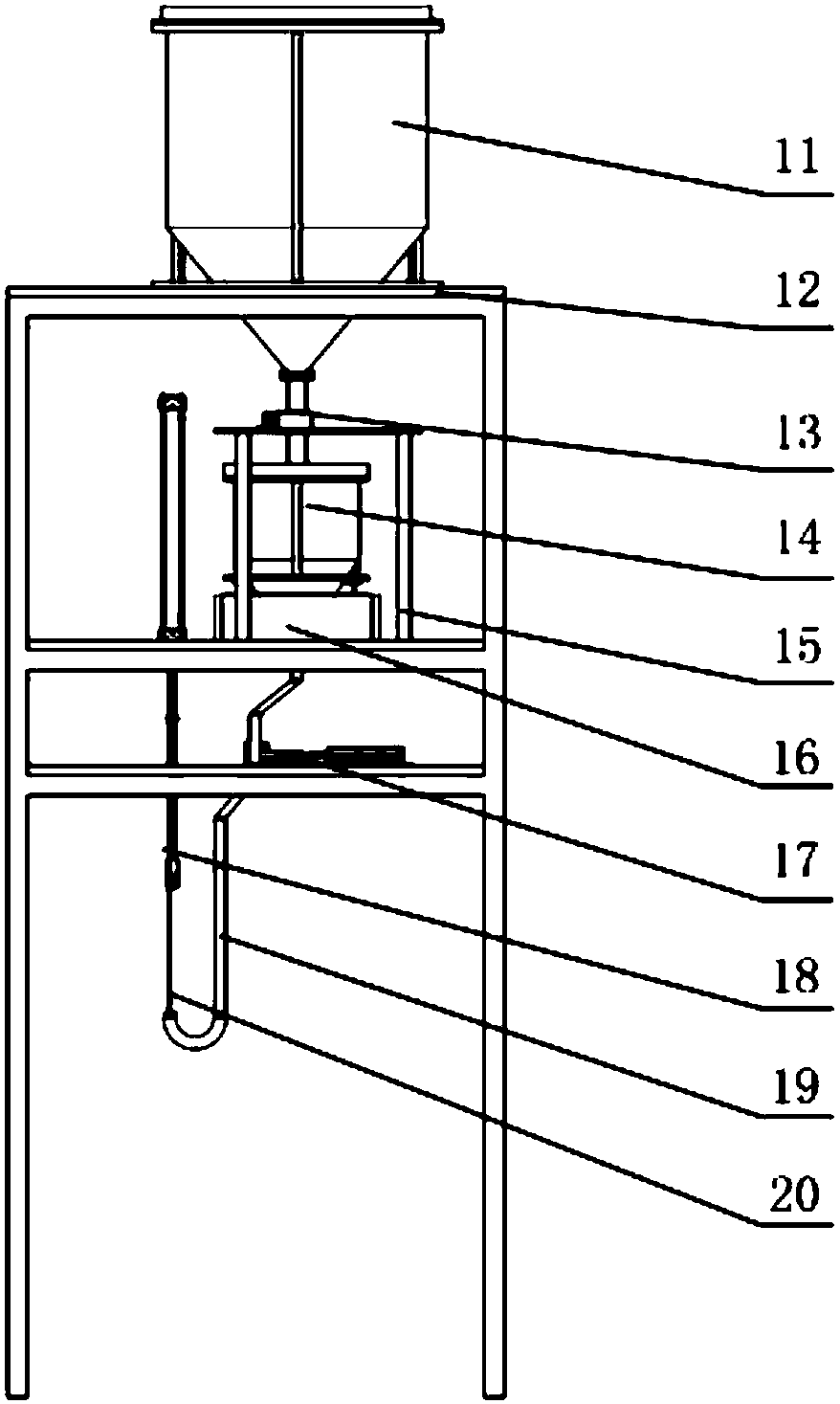

[0030] refer to Figure 1 to Figure 9, The automatic weighing and boxing device for powdery explosives in this embodiment is composed of a roller conveyor line 1, a blanking weighing device 2, a vibration platform 3, an auxiliary device 4, and a finished product packaging platform 5. The roller conveyor line is connected by the first roller conveyor 6, the second roller conveyor 7, the third roller conveyor 8, and the fourth roller conveyor 9 in order of transportation to realize the automatic transportation of products; the roller conveyor Explosion-proof motor, power sprocket roller, and dust-proof treatment; every two power rollers of the roller conveyor are connected by two interlaced chains, and the explosion-proof motor transmits power to the power roller through the sprocket to drive all the rollers Drum turns. Wherein the first roller conveyor 6, the second roller conveyor 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com